Predictive maintenance is an advanced approach to equipment management that leverages data analysis and monitoring techniques to anticipate when machinery is likely to fail. This proactive strategy contrasts sharply with traditional maintenance methods, which often rely on scheduled inspections or reactive repairs after a failure has occurred. By utilizing predictive maintenance, organizations can optimize their maintenance schedules, reduce downtime, and extend the lifespan of their equipment. The concept has gained traction in various industries, including manufacturing, transportation, and energy, as businesses seek to enhance operational efficiency and reduce costs.

The rise of the Internet of Things (IoT) and advancements in data analytics have significantly contributed to the evolution of predictive maintenance. With the ability to collect real-time data from sensors embedded in machinery, organizations can monitor performance metrics continuously. This data-driven approach allows for more informed decision-making regarding maintenance activities. As industries increasingly adopt digital technologies, predictive maintenance is becoming a critical component of asset management strategies.

In exploring the significance of predictive maintenance in preventing industrial failures, it is also essential to consider how technology impacts various aspects of our daily lives, including consumer electronics. A related article that discusses the importance of making informed choices when selecting devices is available at How to Choose a Smartphone for Your Girlfriend. This article highlights the decision-making process in selecting the right technology, which parallels the strategic planning required in implementing predictive maintenance systems in industrial settings.

Key Takeaways

- Predictive maintenance uses data and analytics to anticipate equipment failures before they occur.

- It is crucial in industrial settings for reducing downtime and maintenance costs.

- Key technologies include IoT sensors, machine learning, and real-time monitoring tools.

- Successful implementations demonstrate improved asset lifespan and operational efficiency.

- Challenges include data quality issues and integration complexities, but future trends point to more advanced AI and automation.

The Importance of Predictive Maintenance in Industrial Settings

In industrial environments, equipment reliability is paramount. Unexpected failures can lead to costly downtime, production delays, and safety hazards. Predictive maintenance plays a crucial role in mitigating these risks by enabling organizations to identify potential issues before they escalate into significant problems. By predicting when a machine is likely to fail, companies can schedule maintenance activities during non-peak hours, minimizing disruptions to production processes.

Moreover, predictive maintenance contributes to cost savings by reducing the frequency of unnecessary maintenance tasks. Traditional maintenance schedules often lead to over-maintenance, where equipment is serviced more frequently than necessary. This not only incurs additional labor costs but can also lead to premature wear and tear on components.

By adopting a predictive approach, organizations can focus their resources on maintaining only those assets that require attention, thereby optimizing their maintenance budgets.

How Predictive Maintenance Works

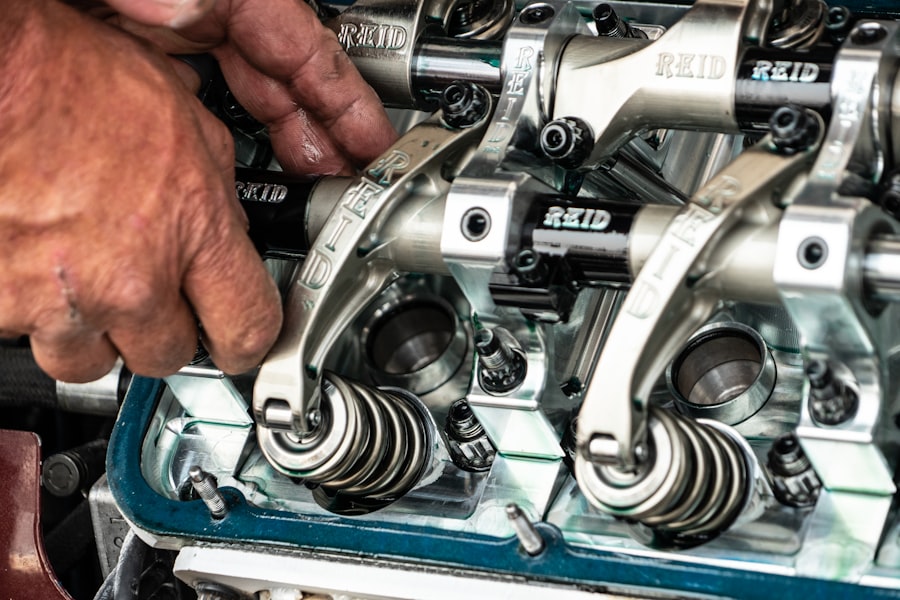

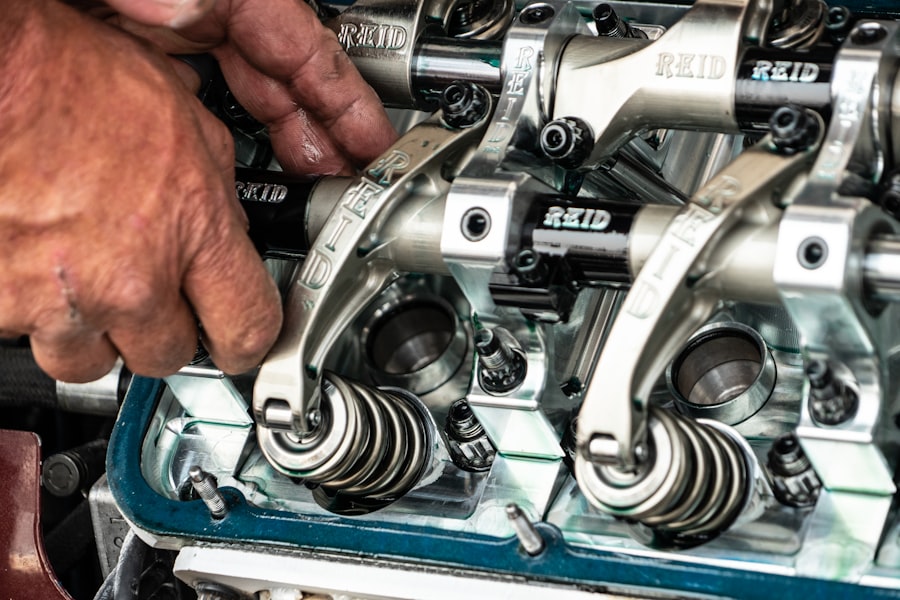

The foundation of predictive maintenance lies in data collection and analysis. Sensors installed on machinery gather various types of data, including temperature, vibration, pressure, and operational speed. This data is transmitted to a centralized system where it is analyzed using algorithms and machine learning techniques. These analytical tools identify patterns and anomalies that may indicate impending failures.

Once potential issues are detected, maintenance teams can be alerted to take action before a breakdown occurs. This process often involves setting thresholds for specific metrics; when these thresholds are exceeded, an alert is generated. Additionally, historical data can be used to refine predictive models, improving their accuracy over time. The integration of artificial intelligence (AI) further enhances the capability of predictive maintenance systems by enabling them to learn from past incidents and adapt to changing conditions.

Benefits of Implementing Predictive Maintenance

The implementation of predictive maintenance offers numerous advantages for organizations across various sectors. One of the most significant benefits is the reduction in unplanned downtime. By addressing potential failures before they occur, companies can maintain continuous operations and avoid the financial repercussions associated with halted production lines. This reliability not only enhances productivity but also improves customer satisfaction by ensuring timely delivery of products and services.

Another key benefit is the extension of equipment lifespan. Regularly monitoring the condition of machinery allows for timely interventions that can prevent severe damage and prolong the operational life of assets. This proactive approach not only saves money on replacement costs but also contributes to sustainability efforts by reducing waste associated with discarded equipment. Furthermore, predictive maintenance fosters a culture of continuous improvement within organizations as teams become more engaged in monitoring performance and optimizing processes.

In exploring the significance of predictive maintenance in preventing industrial failures, it is also interesting to consider how advancements in technology can enhance operational efficiency. For instance, a related article discusses the innovative features of the Samsung Galaxy Chromebook 2 360, which can be leveraged in various industrial applications to streamline processes and improve communication among teams. You can read more about these possibilities in the article found here.

Common Technologies and Tools Used in Predictive Maintenance

| Metric | Description | Impact on Industrial Failures | Example Value |

|---|---|---|---|

| Failure Rate Reduction | Percentage decrease in equipment failures due to predictive maintenance | Lower failure rates lead to fewer unplanned downtimes and increased reliability | 30-50% |

| Mean Time Between Failures (MTBF) | Average operational time between failures | Higher MTBF indicates improved equipment reliability | Increased by 20-40% |

| Maintenance Cost Savings | Reduction in maintenance expenses by avoiding unnecessary repairs | Optimizes resource allocation and reduces operational costs | 15-25% |

| Downtime Reduction | Decrease in unplanned downtime hours | Improves production efficiency and reduces losses | 25-45% |

| Equipment Lifespan Extension | Increase in operational life of machinery | Delays capital expenditure on replacements | 10-20% |

| Early Fault Detection Rate | Percentage of faults detected before failure occurs | Enables proactive maintenance and prevents catastrophic failures | 70-90% |

A variety of technologies and tools are employed in predictive maintenance initiatives. One of the most common is condition monitoring systems that utilize sensors to collect real-time data from equipment. These sensors can measure various parameters such as vibration, temperature, and acoustic emissions, providing valuable insights into the health of machinery.

Data analytics platforms play a crucial role in processing the information gathered from sensors. These platforms often incorporate machine learning algorithms that analyze historical data alongside real-time inputs to identify trends and predict failures. Additionally, visualization tools help maintenance teams interpret complex data sets through dashboards and graphical representations, making it easier to understand equipment performance at a glance.

Cloud computing has also become integral to predictive maintenance strategies, allowing for scalable data storage and processing capabilities. By leveraging cloud-based solutions, organizations can access their data from anywhere and collaborate more effectively across teams. Furthermore, mobile applications enable technicians to receive alerts and access information on-the-go, enhancing responsiveness to potential issues.

In exploring the significance of predictive maintenance in preventing industrial failures, it is also valuable to consider how technology impacts various fields, including the world of design and animation. For instance, a related article discusses the best laptops for Blender in 2023, which can be crucial for professionals looking to enhance their creative workflows. You can read more about it in this