In-situ resource utilization (ISRU) refers to the practice of collecting and processing materials available at a celestial body to create products useful for robotic or human space missions. On Mars, ISRU is a cornerstone for sustainable future exploration, mitigating the prohibitive costs and logistical challenges of transporting everything from Earth. The concept is analogous to pioneers on Earth utilizing local timber and water, rather than shipping all their necessities across oceans. This article focuses on a critical aspect of Martian ISRU: the production of oxygen, a vital component for propulsion, life support, and industrial processes.

The Imperative of Oxygen Production on Mars

Transporting oxygen from Earth to Mars is exceptionally resource-intensive. Every kilogram of oxygen launched from Earth represents a significant investment in fuel, rocket stages, and complex launch infrastructure. For sustained human presence or return missions from Mars, the sheer volume of oxygen required for breathable air and rocket propellant (oxidizer) makes Earth-sourcing impractical. Consider the “tyranny of the rocket equation”: each kilogram of payload requires many more kilograms of propellant to escape Earth’s gravity. Carrying oxygen for both life support and propellant dramatically increases the initial mass, creating a compounding problem. Therefore, producing oxygen directly on Mars is not merely an advantage; it is an enabling technology.

Historical Context and Early Concepts

The idea of using extraterrestrial resources is not new. Early science fiction often depicted resource extraction on other worlds. Scientifically, early proposals for Martian ISRU focused on the atmosphere, recognizing its primary constituent, carbon dioxide, as a potential feedstock. Concepts for oxygen extraction matured alongside advances in material science and energy systems, transitioning from theoretical discussions to concrete engineering proposals in the late 20th and early 21st centuries.

In the context of In-Situ Resource Utilization (ISRU) and the ambitious goal of making oxygen on Mars, it’s interesting to explore how advancements in technology can support space exploration. A related article discusses the latest innovations in smartwatches, which can play a crucial role in monitoring health and performance during space missions. For more insights on cutting-edge technology, you can read the article here: Smartwatches: Fossil Review 2023.

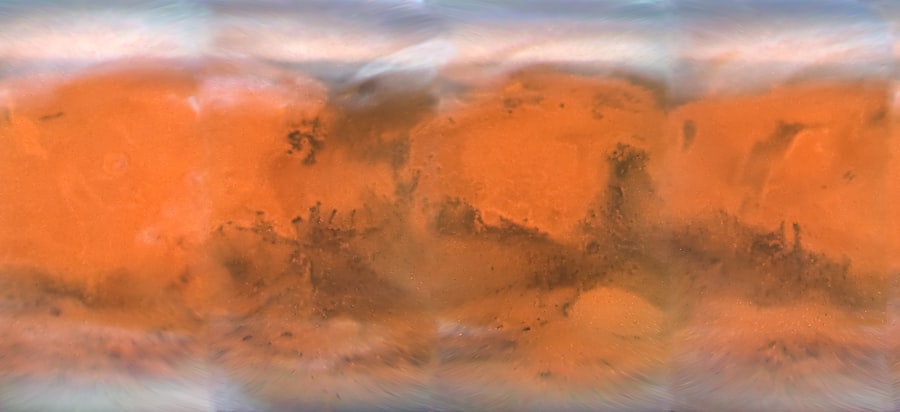

The Martian Atmosphere as a Resource

The Martian atmosphere, while thin, is a readily accessible resource. Its composition, predominantly carbon dioxide (approximately 95.3%), makes it a prime candidate for oxygen production. Despite its low density, the atmosphere is ubiquitous and requires minimal energy to access compared to subsurface or rock-based resources.

Composition and Properties

| Constituent | Percentage (by volume) |

|||

| Carbon Dioxide (CO2) | ~95.32% |

| Nitrogen (N2) | ~2.7% |

| Argon (Ar) | ~1.6% |

| Oxygen (O2) | ~0.13% |

| Carbon Monoxide (CO) | ~0.08% |

| Water Vapor (H2O) | Variable (trace) |

The Martian atmospheric pressure averages around 6 to 10 millibars, less than 1% of Earth’s atmospheric pressure at sea level. This low pressure presents challenges for gas handling, requiring compression systems to achieve sufficient density for processing. The low oxygen content illustrates why direct atmospheric breathing is impossible for humans and why its production is paramount.

Extraction Feasibility

While thin, the Martian atmosphere is a pervasive and replenishable resource. Unlike water ice deposits, which are localized, atmospheric gases are available globally. This simplifies preliminary exploration and site selection for oxygen production facilities. The primary challenge lies in the energy-intensive process of separating and converting carbon dioxide into oxygen.

Primary Methods for Oxygen Production from CO2

Several technologies are being developed and tested for converting atmospheric carbon dioxide into oxygen. These methods generally involve either electrochemical processes or thermal decomposition.

Electrolysis of Carbon Dioxide (Solid Oxide Electrolysis)

One of the most promising methods for oxygen production on Mars is Solid Oxide Electrolysis (SOE). This process utilizes a solid oxide electrolyte (often zirconium dioxide, stabilized with yttria) to conduct oxygen ions at high temperatures (typically 700-1000°C).

The MOXIE Experiment

The Mars Oxygen In-Situ Resource Utilization Experiment (MOXIE) onboard NASA’s Perseverance rover is a pioneering demonstration of SOE technology on Mars. MOXIE was specifically designed to demonstrate the feasibility of producing oxygen directly from the Martian atmosphere.

- Process: Martian atmospheric carbon dioxide is first drawn into MOXIE and filtered to remove dust. It is then compressed and heated. The heated CO2 flows over porous electrodes on opposite sides of a solid oxide electrolyte. A voltage is applied across the electrolyte, causing oxygen atoms from the CO2 molecules to lose electrons at the cathode (negative electrode), become oxygen ions (O2-), and migrate through the electrolyte to the anode (positive electrode). At the anode, these oxygen ions recombine, gaining electrons to form diatomic oxygen molecules (O2), which are then vented. The remaining carbon monoxide (CO) is also vented.

- Outputs: MOXIE produces pure oxygen gas and carbon monoxide as a byproduct. While MOXIE’s primary objective is oxygen production, the carbon monoxide byproduct is also a potential propellant component or industrial feedstock.

- Significance: MOXIE has successfully demonstrated the production of oxygen on Mars under actual Martian conditions since April 2021. This proof of concept is a critical step towards establishing full-scale oxygen production plants. The continuous operation of MOXIE, even in small quantities (approximately 6 grams per hour, equivalent to what a small tree produces on Earth), validates the core technology.

Advantages and Challenges of SOE

- Advantages:

- High efficiency at high temperatures.

- Direct conversion of CO2 to O2.

- Proven technology (on Earth for industrial applications, and now demonstrated on Mars).

- Potential for integration with nuclear power sources providing consistent high temperature.

- Challenges:

- Requires high operating temperatures, necessitating robust heaters and insulation.

- Vulnerable to thermal cycling stresses.

- Contaminants in the CO2 stream (e.g., dust) can degrade electrolyte performance.

- Requires significant power input.

Reverse Water-Gas Shift Reaction (RWGS) and Electrolysis

Another approach involves a two-step process:

- Reverse Water-Gas Shift (RWGS) Reaction: CO2 + H2 → CO + H2O

This reaction converts carbon dioxide and hydrogen into carbon monoxide and water. The hydrogen can be recycled or sourced from water ice if available.

- Water Electrolysis: 2H2O → 2H2 + O2

The water produced in the RWGS reaction is then electrolyzed to produce oxygen and regenerate hydrogen.

Synergies with Hydrogen Resources

The RWGS approach emphasizes the importance of hydrogen. If hydrogen can be efficiently sourced from Martian water ice, this method becomes particularly attractive. The ability to recycle hydrogen within the system would make it a closed-loop operation for oxygen production from CO2. The challenge lies in initially acquiring that hydrogen.

Advantages and Challenges of RWGS + Electrolysis

- Advantages:

- Lower operating temperatures than SOE for the RWGS step.

- Water electrolysis is a well-understood and reliable technology.

- Potentially higher overall oxygen output if hydrogen is readily available.

- Challenges:

- Requires a supply of hydrogen, which is a resource that needs to be generated or transported.

- Two separate reactors and processes, increasing system complexity.

- Potential for catalyst degradation in RWGS.

Molten Carbonate Electrolysis

This method operates at intermediate temperatures (approx. 500-700°C) using a molten carbonate salt as the electrolyte. Carbon dioxide dissolves in the molten salt and is then electrolyzed.

- Process: CO2 + 2e− → CO + O2− (at cathode) and O2− → ½O2 + 2e− (at anode)

- Advantages: Can achieve high current densities. Lower operating temperatures than SOE.

- Challenges: Corrosive nature of molten salts. Containment and management of molten salts in microgravity or reduced gravity environments.

Energy Requirements and Power Sources

Oxygen production on Mars is an energy-intensive endeavor. The power source is as critical as the oxygen extraction technology itself.

Solar Power

Solar panels are a proven technology for powering Mars missions, as demonstrated by numerous rovers and landers.

Advantages and Limitations

- Advantages: Relatively straightforward to deploy, no fuel required, mature technology.

- Limitations:

- Dust Accumulation: Martian dust storms and daily dust deposition significantly reduce solar panel efficiency and output. Regular cleaning mechanisms (e.g., electrostatic dust wipers or robot brushes) would be necessary.

- Nighttime Operations: Solar panels cease to produce power during the Martian night. For continuous oxygen production, a robust energy storage system (batteries) would be needed, adding mass and complexity.

- Seasonal and Latitudinal Dependence: Solar insolation varies with seasons and latitude on Mars, impacting power availability. Higher latitudes experience longer periods of darkness during winter.

Nuclear Power (Radioisotope Thermoelectric Generators & Fission Reactors)

Nuclear power offers a consistent and high-output energy solution, largely independent of solar cycles or dust storms.

Radioisotope Thermoelectric Generators (RTGs)

RTGs use the heat generated by the decay of a radioactive isotope (e.g., Plutonium-238) to produce electricity via thermocouples.

- Advantages: Continuous power output, robust, long lifespan.

- Limitations: Low power output compared to fission reactors, limited supply of Plutonium-238, safety concerns during launch. Suitable for small-scale applications.

Fission Reactors

Small fission reactors are being developed for space applications, offering significantly higher power output than RTGs.

- Advantages: High power output, continuous operation, independent of solar conditions.

- Limitations: Complex shielding requirements, significant mass, regulatory hurdles, safety considerations. Fission reactors are considered essential for large-scale industrial ISRU operations, acting as the “heart” of the Martian factory.

In the quest for sustainable human exploration of Mars, In-Situ Resource Utilization (ISRU) plays a crucial role, particularly in the production of oxygen from the Martian atmosphere. This innovative approach not only aims to support life but also reduces the need to transport large quantities of supplies from Earth. For those interested in learning more about the advancements in space technology, a related article discusses the latest developments in this field and can be found here. Understanding ISRU is essential for future missions, as it represents a significant step toward making long-term human presence on Mars a reality.

Storage and Utilization of Produced Oxygen

| Metric | Value | Unit | Description |

|---|---|---|---|

| Oxygen Production Rate | 10 | grams/hour | Amount of oxygen produced by MOXIE prototype on Mars |

| Carbon Dioxide Concentration | 95.3 | percent | Concentration of CO2 in Martian atmosphere used for oxygen extraction |

| Power Consumption | 300 | watts | Energy required to operate oxygen production unit |

| Operating Temperature | 800 | °C | Temperature at which CO2 is electrolyzed to produce oxygen |

| Oxygen Purity | 99.6 | percent | Purity level of oxygen produced by ISRU system |

| System Mass | 17 | kilograms | Mass of MOXIE oxygen production unit |

| Duration of Operation | 4 | hours | Typical continuous operation time for oxygen production test |

Producing oxygen is only part of the equation; it must also be stored and utilized effectively.

Oxygen Storage Mechanisms

- Cryogenic Storage: Storing oxygen as a liquid (LOX) requires extremely low temperatures (-183°C), necessary for high-density storage. This involves complex cryogenic chillers and insulated tanks, which are energy-intensive to operate and maintain, but offer the most efficient volume storage.

- High-Pressure Gas Storage: Storing oxygen as a high-pressure gas is simpler than cryogenic storage but requires larger, heavier tanks for the same amount of oxygen. This method is less ideal for large volumes needed for rocket propellant.

- Adsorption/Absorption: Utilizing materials that can reversibly bind oxygen. This method is still largely in research and development for space applications, potentially offering a safer alternative to high-pressure or cryogenic storage.

Applications of Martian Oxygen

Life Support

Oxygen is the fundamental component of breathable air for human habitats on Mars. A typical human requires about 0.84 kilograms of oxygen per day. For a crew of four, this translates to over 3 kilograms daily, highlighting the continuous demand.

Propellant Production

A critical application is as an oxidizer for rocket propellant. Methane/oxygen (CH4/O2) or hydrogen/oxygen (H2/O2) are common propellant combinations. For humans to return from Mars, a substantial amount of oxygen (tens of tons) is needed to fuel the ascent vehicle. This is likely the single largest demand for Martian oxygen. For example, a Mars Ascent Vehicle might require 25-30 tons of oxygen.

Industrial Processes

Beyond life support and propulsion, oxygen could be used in various industrial processes, such as:

- Processing of Martian Regolith: Oxygen can be used in chemical reactions to extract metals or other valuable materials from the Martian soil.

- Construction: As part of construction material fabrication, though the exact methods are still exploratory.

- Scientific Instruments: Some scientific instruments might require oxygen for specific operations or calibrations.

Future Outlook and Challenges

The successful demonstration of MOXIE is a significant milestone, but large-scale oxygen production on Mars faces numerous engineering, logistical, and economic challenges.

Scaling Up Production

MOXIE produces oxygen at a rate suitable for a small proof-of-concept. Scaling up to meet the demands of human missions (tens of tons) requires significantly larger reactors, more powerful energy sources, and robust dust mitigation systems. This transition from laboratory-scale to industrial-scale represents a substantial engineering hurdle.

Reliability and Longevity

Any ISRU system on Mars must operate reliably for extended periods in a harsh, remote environment without direct human intervention for troubleshooting. The Martian dust and extreme temperature swings pose significant challenges to the longevity of mechanical and electrical systems.

Dust Mitigation

Martian dust is ubiquitous and highly abrasive. It can clog filters, coat solar panels, abrade moving parts, and interfere with electronics. Effective, self-cleaning dust mitigation strategies are essential for sustained operations.

Integration with Other ISRU Technologies

Oxygen production is part of a larger ISRU ecosystem. Its effectiveness will be amplified when integrated with other resource extraction methods, such as water ice mining for hydrogen (for RWGS or direct H2/O2 propellant), and mineral processing. A truly sustainable Martian outpost will function as a self-sufficient industrial complex, with oxygen production as a cornerstone.

Economic Viability

Ultimately, the long-term success of ISRU on Mars depends on its economic viability. While the initial investment is high, the cost savings from not transporting resources from Earth are substantial. Detailed economic models are crucial to guide investment and development decisions, illustrating that the “return on investment” isn’t purely monetary, but measured in mission capability and human survival.

The journey to making oxygen on Mars is a testament to human ingenuity and our relentless push to expand our presence beyond Earth. It encapsulates the spirit of space exploration: not just visiting, but truly living and thriving on another world.

FAQs

What is In-Situ Resource Utilization (ISRU)?

In-Situ Resource Utilization (ISRU) refers to the practice of collecting and using materials found or manufactured on other planets or moons to support space missions, rather than bringing all supplies from Earth. This approach helps reduce mission costs and increases sustainability.

Why is making oxygen on Mars important for space missions?

Producing oxygen on Mars is crucial because it supports human life by providing breathable air and can be used as rocket propellant. Generating oxygen locally reduces the need to transport large amounts of oxygen from Earth, making long-term missions more feasible.

How is oxygen produced on Mars using ISRU technology?

Oxygen on Mars can be produced by extracting it from the carbon dioxide-rich Martian atmosphere. One common method involves using a device called a MOXIE (Mars Oxygen In-Situ Resource Utilization Experiment), which electrolyzes carbon dioxide (CO2) to separate oxygen (O2) and carbon monoxide (CO).

What are the challenges of producing oxygen on Mars?

Challenges include the harsh Martian environment, such as low temperatures, dust storms, and limited energy availability. Additionally, the technology must be reliable and efficient to operate autonomously for extended periods without maintenance.

Has oxygen production on Mars been tested in space missions?

Yes, NASA’s Perseverance rover, which landed on Mars in 2021, carries the MOXIE experiment. MOXIE has successfully demonstrated the production of oxygen from the Martian atmosphere, marking a significant milestone for ISRU technology.