The increasing volume of waste generated globally has necessitated the development of more efficient waste management systems. Robotics has emerged as a pivotal technology in the field of waste sorting and recycling, offering innovative solutions to address the challenges posed by traditional methods.

As urbanization and consumerism continue to rise, the need for effective waste management becomes more pressing.

Robotics in this sector not only enhances operational efficiency but also contributes to environmental sustainability by improving recycling rates and reducing landfill dependency.

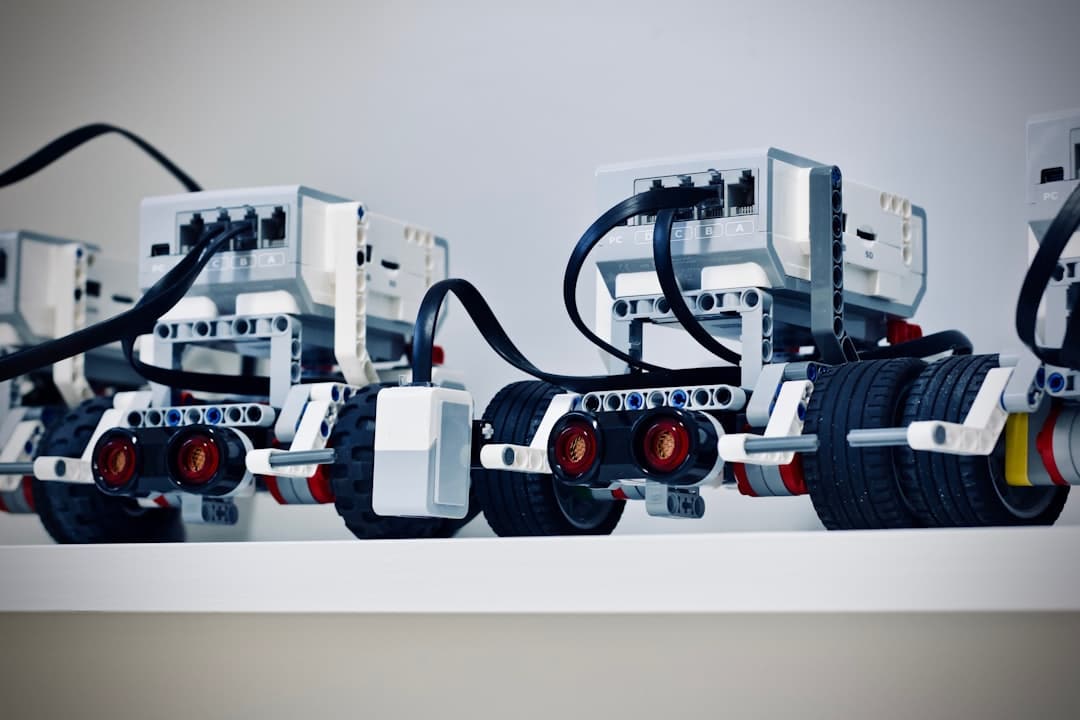

The integration of robotics into waste sorting processes represents a significant shift in how materials are processed. Automated systems are being designed to handle various types of waste, from plastics to metals, with the aim of maximizing recovery rates. This technological advancement is not merely about replacing human labor; it is about augmenting existing processes to create a more streamlined and effective waste management system. As the industry evolves, the role of robotics is expected to expand, leading to more sophisticated solutions that can adapt to changing waste streams and recycling requirements.

In exploring the advancements in technology that enhance waste management processes, a related article discusses the latest innovations in laptops, which can play a crucial role in developing software for robotics in recycling. For instance, the article on the best HP laptops of 2023 highlights powerful computing devices that can support sophisticated algorithms used in robotics for waste sorting. You can read more about it here: the best HP laptop 2023.

Key Takeaways

- Robotics significantly improves waste sorting and recycling efficiency through automation.

- Enhanced accuracy and speed reduce errors and increase processing capacity.

- Integration with AI and machine learning enables smarter, adaptive sorting systems.

- Robotics reduces human exposure to hazardous waste, improving workplace safety.

- Future innovations promise greater sustainability and cost-effective resource management.

Automation of Sorting Processes

The automation of sorting processes in waste management has revolutionized how materials are separated and processed. Traditional sorting methods often rely on manual labor, which can be slow and inconsistent. In contrast, robotic systems utilize advanced sensors and mechanical arms to identify and sort materials with precision. These automated systems can operate continuously, significantly increasing throughput and efficiency in recycling facilities. By automating the sorting process, facilities can handle larger volumes of waste while maintaining a high level of accuracy.

Moreover, automation allows for the implementation of standardized sorting protocols that can be replicated across different facilities. This consistency is crucial for ensuring that recyclable materials are properly identified and processed. Automated sorting systems can be programmed to recognize various materials based on size, shape, and composition, enabling them to sort items more effectively than human workers. As technology advances, these systems are becoming increasingly sophisticated, incorporating features such as real-time data analysis and adaptive learning capabilities that enhance their performance over time.

Enhanced Accuracy and Speed in Sorting

One of the primary advantages of robotics in waste sorting is the enhanced accuracy and speed with which materials can be processed.

Robotic systems equipped with advanced imaging technologies, such as machine vision, can quickly analyze items on a conveyor belt and make sorting decisions in fractions of a second.

This rapid processing capability not only increases the volume of materials sorted but also reduces contamination rates, which is critical for maintaining the quality of recyclables.

In addition to speed, the accuracy of robotic sorting systems minimizes the risk of misclassification. Human workers may inadvertently overlook or misidentify items due to fatigue or distraction, leading to inefficiencies and increased costs. In contrast, robots can consistently apply their programmed criteria without variation. This reliability is particularly important in recycling operations where the purity of sorted materials directly impacts their market value. As a result, facilities that implement robotic sorting technologies often see improved financial returns from their recycling efforts.

Reduction of Human Error and Occupational Hazards

The introduction of robotics into waste sorting processes significantly reduces human error and mitigates occupational hazards associated with manual sorting. Waste management can be a dangerous field, with workers exposed to sharp objects, hazardous materials, and unsanitary conditions. By employing robotic systems for sorting tasks, facilities can minimize the risk of injury to human workers while also improving overall safety standards.

Furthermore, robots are not susceptible to fatigue or stress, which are common factors that contribute to human error in high-pressure environments. This reliability ensures that sorting processes remain consistent throughout operational hours. The reduction of human involvement in potentially hazardous tasks allows workers to focus on more complex roles that require human judgment and decision-making skills. As a result, the workforce can be reallocated to areas where their expertise is most valuable, enhancing both safety and productivity within the facility.

In exploring the potential of robotics to enhance efficiency in waste sorting and recycling, it is also valuable to consider how technology can streamline other sectors. For instance, the article on the best software for social media content provides insights into how automation can optimize content management and distribution, much like robotics can improve the sorting process in recycling facilities. This intersection of technology across different fields highlights the broader implications of automation in enhancing operational efficiency.

Integration of Robotics with AI and Machine Learning

| Metric | Traditional Waste Sorting | Robotics-Enhanced Waste Sorting | Improvement |

|---|---|---|---|

| Sorting Speed (tons/hour) | 1.5 | 5.0 | 233% increase |

| Sorting Accuracy (%) | 85 | 98 | 15% increase |

| Labor Requirement (workers per shift) | 20 | 5 | 75% reduction |

| Contamination Rate in Sorted Materials (%) | 12 | 3 | 75% reduction |

| Operational Hours (hours/day) | 16 | 24 | 50% increase |

| Energy Consumption (kWh/ton) | 50 | 40 | 20% reduction |

| Recycling Yield (%) | 60 | 85 | 42% increase |

The integration of robotics with artificial intelligence (AI) and machine learning has further advanced the capabilities of waste sorting systems. AI algorithms enable robots to learn from their environment and improve their sorting accuracy over time. By analyzing vast amounts of data from previous sorting operations, these systems can adapt to new types of waste and optimize their performance accordingly.

Machine learning models can also enhance predictive maintenance for robotic systems, allowing facilities to anticipate equipment failures before they occur. This proactive approach minimizes downtime and ensures that sorting operations run smoothly. Additionally, AI-driven analytics can provide insights into waste composition trends, helping facilities make informed decisions about resource allocation and operational improvements. The synergy between robotics and AI is transforming waste management into a more intelligent and responsive industry.

In exploring the advancements in waste management, a fascinating article discusses how social media platforms are adapting to user preferences, which indirectly highlights the importance of personalization in technology. You can read more about this in the article on Instagram’s new feature for pronouns, which emphasizes the growing trend of tailoring technology to individual needs. This concept of customization is also relevant in the context of robotics, as innovations in waste sorting and recycling can significantly enhance efficiency and effectiveness in managing our resources. For more insights, check out the article here.

Cost Efficiency and Resource Optimization

Implementing robotics in waste sorting not only enhances operational efficiency but also leads to significant cost savings for recycling facilities. The initial investment in robotic technology can be offset by reductions in labor costs and increased throughput. Automated systems require less human oversight, allowing facilities to operate with fewer staff while maintaining or even increasing productivity levels.

Resource optimization is another critical benefit of robotic sorting systems. By improving the accuracy of material separation, facilities can maximize the recovery of valuable recyclables while minimizing contamination rates. This optimization translates into higher-quality output that commands better prices in the recycling market. Additionally, efficient sorting processes reduce the amount of waste sent to landfills, contributing to overall cost savings associated with disposal fees and environmental compliance.

Environmental Impact and Sustainability

The environmental impact of robotics in waste sorting extends beyond operational efficiency; it plays a crucial role in promoting sustainability within the waste management sector. By enhancing recycling rates and reducing landfill dependency, robotic systems contribute to a circular economy where materials are reused rather than discarded. This shift not only conserves natural resources but also reduces greenhouse gas emissions associated with waste decomposition.

Moreover, the ability of robotic systems to accurately sort materials ensures that more recyclables are diverted from landfills, thereby decreasing the environmental footprint of waste management operations. As public awareness of environmental issues grows, there is increasing pressure on industries to adopt sustainable practices. Robotics offers a viable solution for meeting these demands while simultaneously improving economic outcomes for recycling facilities.

Future Trends and Innovations in Robotics for Waste Management

Looking ahead, the future of robotics in waste management is poised for continued innovation and growth. Emerging technologies such as collaborative robots (cobots) are expected to play a significant role in enhancing human-robot interactions within recycling facilities. These cobots can work alongside human workers, assisting them with tasks that require precision while allowing humans to focus on more complex decision-making processes.

Additionally, advancements in sensor technology and AI will likely lead to even more sophisticated sorting capabilities. Future robotic systems may be able to identify not only traditional recyclables but also complex composite materials that are currently challenging to sort effectively. As research continues into new materials and recycling methods, robotics will remain at the forefront of developing solutions that address evolving waste management challenges.

In conclusion, robotics has fundamentally transformed the landscape of waste sorting and recycling by enhancing efficiency, accuracy, safety, and sustainability. As technology continues to advance, its integration into waste management practices will likely expand further, paving the way for innovative solutions that address both current challenges and future demands in this critical sector.

FAQs

What role do robots play in waste sorting and recycling?

Robots assist in waste sorting and recycling by automating the identification, separation, and processing of recyclable materials. They use sensors, cameras, and AI algorithms to accurately sort different types of waste, improving efficiency and reducing human error.

How does robotics improve the efficiency of waste sorting?

Robotics improves efficiency by speeding up the sorting process, increasing accuracy in material identification, reducing contamination, and enabling continuous operation without fatigue. This leads to higher throughput and better quality of sorted recyclables.

What technologies are commonly used in robotic waste sorting systems?

Common technologies include machine learning, computer vision, infrared sensors, robotic arms, and conveyor systems. These technologies work together to detect, classify, and separate various types of waste materials.

Can robotics reduce the environmental impact of waste management?

Yes, robotics can reduce environmental impact by enhancing recycling rates, minimizing landfill use, and lowering the energy consumption associated with manual sorting. Efficient sorting also helps recover more materials for reuse, conserving natural resources.

Are robotic waste sorting systems cost-effective?

While initial investment in robotic systems can be high, they often prove cost-effective over time by reducing labor costs, increasing sorting speed, and improving material recovery rates, which can generate additional revenue from recyclables.

What types of waste can robots sort?

Robots can sort a variety of waste types including plastics, metals, paper, glass, and electronic waste. Advanced systems can differentiate between subtypes, such as different plastic polymers, to enhance recycling quality.

How do robots handle hazardous or complex waste materials?

Robotic systems can be equipped with specialized sensors and safety protocols to identify and safely handle hazardous or complex waste, reducing risks to human workers and ensuring proper disposal or recycling.

Is human involvement still necessary in robotic waste sorting?

Yes, human oversight is typically required for system maintenance, quality control, and handling materials that robots cannot process. Humans also manage exceptions and ensure the overall system operates effectively.

What are the future trends in robotics for waste sorting and recycling?

Future trends include increased use of AI for better material recognition, integration with smart waste management systems, development of more adaptable and flexible robots, and expansion into sorting more complex waste streams like textiles and organics.