Augmented Reality (AR) has emerged as a transformative technology in various sectors, with manufacturing being one of the most significantly impacted industries. By overlaying digital information onto the physical world, AR enhances the way workers interact with machinery, tools, and processes. This technology allows for real-time data visualization, which can lead to improved decision-making and operational efficiency.

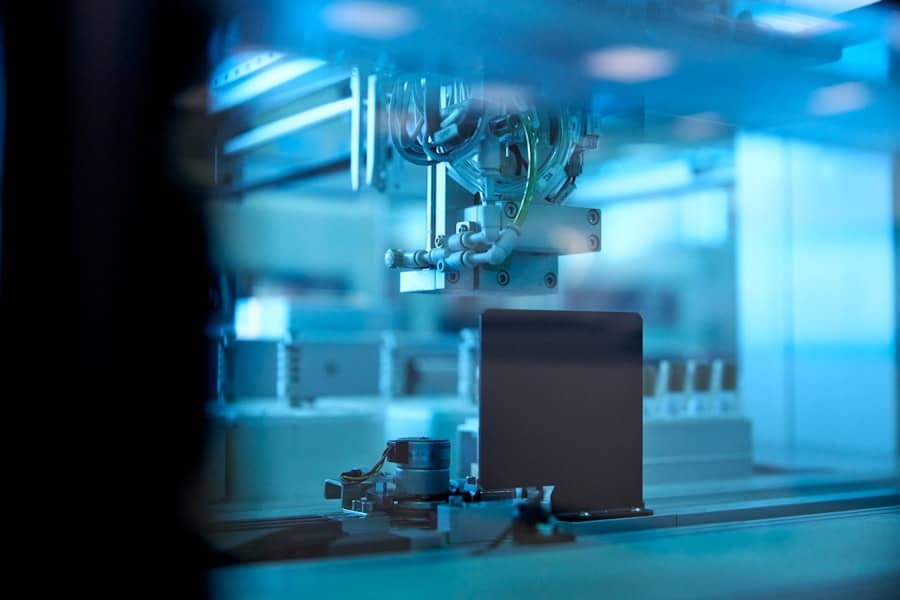

In manufacturing, where precision and speed are paramount, AR provides a unique solution to age-old challenges, such as training inefficiencies, maintenance delays, and error-prone manual processes. The integration of AR into manufacturing processes is not merely a trend; it represents a paradigm shift in how companies approach production and maintenance. With the advent of smart glasses and mobile devices equipped with AR capabilities, workers can access critical information hands-free while performing their tasks.

This capability is particularly beneficial in complex environments where multitasking is essential. As manufacturers continue to seek ways to optimize their operations, the adoption of AR technologies is becoming increasingly prevalent, paving the way for a more connected and efficient future.

Key Takeaways

- AR enhances maintenance and repair by providing real-time, hands-on guidance in manufacturing settings.

- Case studies show AR improves efficiency, accuracy, and reduces downtime during maintenance tasks.

- AR plays a crucial role in training and onboarding, accelerating skill development for maintenance workers.

- Challenges include technical limitations, cost, and integration with existing systems in manufacturing environments.

- Future trends point to more advanced AR features, greater adoption, and seamless integration in manufacturing maintenance.

The Benefits of AR for Maintenance and Repair

One of the most significant advantages of AR in maintenance and repair is its ability to provide real-time guidance to technicians. By superimposing digital instructions directly onto the equipment being serviced, AR enables workers to follow step-by-step procedures without needing to consult manuals or other resources. This immediate access to information reduces the time spent searching for solutions and minimizes the risk of errors during repairs.

For instance, a technician repairing a complex assembly line machine can see visual cues indicating where to apply tools or how to adjust components, streamlining the entire process. Moreover, AR enhances collaboration among team members, especially in scenarios where expertise is required from remote locations. With AR-enabled devices, technicians can share their view of the equipment with experts who may be miles away.

This capability allows for real-time troubleshooting and guidance, significantly reducing downtime. For example, if a machine malfunctions, an on-site technician can connect with a remote specialist who can see exactly what they see and provide immediate assistance. This collaborative approach not only speeds up repairs but also fosters knowledge sharing within organizations.

Case Studies of AR Implementation in Manufacturing

Several companies have successfully implemented AR technologies in their manufacturing processes, showcasing the tangible benefits of this innovation. One notable example is Boeing, which has integrated AR into its assembly lines for aircraft manufacturing. By using AR glasses, technicians can visualize wiring diagrams and assembly instructions directly overlaid on the aircraft components they are working on.

This application has led to a significant reduction in assembly errors and has improved overall efficiency by allowing workers to complete tasks more quickly and accurately. Another compelling case is that of Siemens, which has utilized AR for maintenance training in its gas turbine manufacturing facilities. Siemens developed an AR application that provides trainees with interactive 3D models of gas turbines, allowing them to explore components and understand their functions in a virtual environment.

This immersive training experience has proven to be more effective than traditional methods, resulting in faster onboarding times and better-prepared employees. The success of these implementations highlights how AR can revolutionize not only maintenance practices but also training methodologies within the manufacturing sector.

How AR is Improving Efficiency and Accuracy in Maintenance and Repair

The efficiency gains from AR in maintenance and repair are multifaceted. First and foremost, the technology reduces the cognitive load on technicians by providing them with contextual information at their fingertips. Instead of memorizing complex procedures or constantly referring to manuals, workers can focus on executing tasks with the guidance of AR overlays.

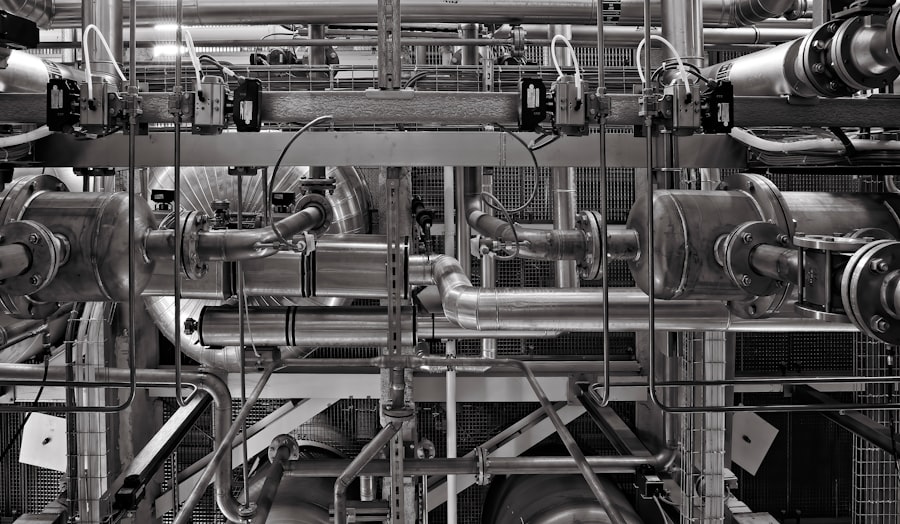

This shift not only speeds up the repair process but also enhances accuracy by minimizing the likelihood of human error. Additionally, AR facilitates predictive maintenance by integrating with IoT sensors embedded in machinery. These sensors collect data on equipment performance and health, which can be analyzed to predict potential failures before they occur.

When combined with AR, this data can be visualized in real-time, allowing technicians to address issues proactively rather than reactively. For instance, if a sensor detects abnormal vibrations in a motor, an AR application can alert the technician while providing visual instructions on how to inspect or replace the component before it leads to a breakdown. This proactive approach not only saves time but also extends the lifespan of equipment.

The Role of AR in Training and Onboarding Maintenance and Repair Workers

| Metric | Before AR Implementation | After AR Implementation | Improvement | Source/Notes |

|---|---|---|---|---|

| Average Maintenance Time | 4 hours | 2.5 hours | 37.5% reduction | AR-guided step-by-step instructions reduce troubleshooting time |

| First-Time Fix Rate | 65% | 85% | 20 percentage points increase | Remote expert assistance and real-time data improve accuracy |

| Downtime per Incident | 6 hours | 3.5 hours | 41.7% reduction | Faster diagnostics and repair with AR overlays |

| Training Time for Technicians | 40 hours | 25 hours | 37.5% reduction | AR simulations and interactive manuals accelerate learning |

| Error Rate During Repairs | 12% | 5% | 58.3% reduction | Real-time guidance minimizes human errors |

| Cost of Maintenance per Incident | 1200 | 800 | 33.3% reduction | Efficiency gains and reduced downtime lower costs |

Training new maintenance and repair workers has traditionally been a resource-intensive process that often relies on shadowing experienced technicians or studying lengthy manuals. However, AR is revolutionizing this aspect of workforce development by providing immersive training experiences that enhance learning retention and engagement. Through interactive simulations and guided tutorials, new hires can practice their skills in a risk-free environment before working on actual equipment.

For example, companies like General Electric have developed AR training programs that allow employees to interact with virtual representations of complex machinery. Trainees can manipulate 3D models to understand how different components fit together and function without the fear of damaging real equipment. This hands-on approach not only accelerates the learning curve but also instills confidence in new workers as they transition into their roles.

Furthermore, as experienced technicians share their knowledge through AR applications, they contribute to a culture of continuous learning within the organization.

Challenges and Limitations of AR in Maintenance and Repair

Despite its numerous advantages, the implementation of AR in maintenance and repair is not without challenges. One significant barrier is the initial investment required for AR technology deployment. Companies must consider the costs associated with hardware, software development, and training personnel to use these new systems effectively.

For smaller manufacturers or those operating on tight budgets, these upfront costs can be prohibitive. Another challenge lies in the integration of AR with existing systems and workflows. Many manufacturing environments rely on legacy systems that may not be compatible with modern AR applications.

Ensuring seamless integration requires careful planning and may necessitate additional investments in infrastructure upgrades or custom software solutions. Additionally, there may be resistance from employees who are accustomed to traditional methods of working and may be hesitant to adopt new technologies.

Future Trends and Developments in AR for Manufacturing Maintenance and Repair

As technology continues to evolve, so too will the applications of AR in manufacturing maintenance and repair. One emerging trend is the increasing use of artificial intelligence (AI) alongside AR technologies. AI algorithms can analyze vast amounts of data collected from machinery and provide insights that enhance AR applications’ effectiveness.

For instance, AI could help identify patterns in equipment failures that inform predictive maintenance strategies displayed through AR interfaces. Furthermore, advancements in wearable technology are likely to play a crucial role in the future of AR in manufacturing. Smart glasses equipped with enhanced capabilities will become more prevalent, allowing technicians to access information more intuitively while keeping their hands free for tasks.

As 5G networks expand globally, the speed and reliability of data transmission will improve significantly, enabling more complex AR applications that require real-time data processing.

Conclusion and Recommendations for Implementing AR in Manufacturing

To successfully implement AR technologies in manufacturing maintenance and repair processes, organizations should begin by conducting a thorough assessment of their current workflows and identifying areas where AR could provide the most significant impact. Engaging stakeholders from various departments—such as IT, operations, and human resources—will ensure that all perspectives are considered during the planning phase. Investing in pilot programs can also be an effective strategy for testing AR applications before full-scale deployment.

By starting small and gradually expanding based on feedback and results, companies can mitigate risks associated with large-scale implementation while demonstrating tangible benefits to stakeholders. Additionally, fostering a culture of innovation within the organization will encourage employees to embrace new technologies like AR rather than resist them.

By leveraging this technology effectively, manufacturers can enhance efficiency, accuracy, and training outcomes—ultimately leading to improved operational performance and competitiveness in an increasingly digital landscape.

Augmented Reality (AR) is revolutionizing the maintenance and repair processes in manufacturing by providing technicians with real-time, interactive guidance, which significantly reduces downtime and enhances efficiency. For those interested in exploring how technology can further optimize manufacturing processes, a related article on 3D printing software can be insightful. You can read more about it in this article: Best Software for 3D Printing.

FAQs

What is Augmented Reality (AR) in manufacturing maintenance?

Augmented Reality (AR) in manufacturing maintenance refers to the use of AR technology to overlay digital information, such as instructions, diagrams, or real-time data, onto physical equipment. This helps technicians perform maintenance and repair tasks more efficiently and accurately.

How does AR improve maintenance and repair processes?

AR improves maintenance and repair by providing technicians with hands-free access to step-by-step instructions, real-time diagnostics, and remote expert support. This reduces errors, shortens downtime, and speeds up troubleshooting and repairs.

What types of AR devices are commonly used in manufacturing?

Common AR devices in manufacturing include smart glasses, head-mounted displays, tablets, and smartphones. These devices enable technicians to view augmented information while working on machinery without interrupting their workflow.

Can AR be integrated with existing manufacturing systems?

Yes, AR can be integrated with existing manufacturing systems such as Enterprise Resource Planning (ERP), Computerized Maintenance Management Systems (CMMS), and Internet of Things (IoT) platforms to provide real-time data and streamline maintenance operations.

What are the benefits of using AR for maintenance training?

AR enhances maintenance training by offering immersive, interactive simulations that allow technicians to practice procedures safely and repeatedly. This leads to faster skill acquisition, better retention, and reduced training costs.

Does AR help reduce maintenance costs?

Yes, AR helps reduce maintenance costs by minimizing equipment downtime, decreasing the need for expert travel, lowering error rates, and improving overall maintenance efficiency.

Is AR suitable for all types of manufacturing equipment?

AR is versatile and can be adapted for a wide range of manufacturing equipment, from simple machines to complex automated systems. However, the effectiveness depends on the availability of digital models and integration capabilities.

How does AR support remote assistance in maintenance?

AR enables remote experts to see what on-site technicians see through AR devices and provide real-time guidance, annotations, and instructions. This reduces the need for expert travel and accelerates problem resolution.

What challenges might manufacturers face when implementing AR?

Challenges include the initial cost of AR hardware and software, integration with legacy systems, training employees to use AR tools effectively, and ensuring data security and privacy.

What is the future outlook for AR in manufacturing maintenance?

The future outlook is positive, with ongoing advancements in AR technology expected to further enhance predictive maintenance, automation, and real-time data analytics, making maintenance and repair processes even more efficient and cost-effective.