The integration of artificial intelligence (AI) algorithms into food processing has revolutionized the industry, enhancing efficiency, safety, and quality. AI algorithms, which are designed to analyze data, learn from patterns, and make decisions, have found numerous applications in food processing, from supply chain management to quality control. The food industry, characterized by its complexity and the need for precision, has increasingly turned to AI to address challenges such as waste reduction, product consistency, and labor shortages.

By leveraging vast amounts of data generated throughout the food production process, AI algorithms can optimize operations and improve decision-making. The adoption of AI in food processing is not merely a trend; it represents a fundamental shift in how food is produced, processed, and delivered. Traditional methods often rely on manual labor and experience-based decision-making, which can lead to inefficiencies and inconsistencies.

In contrast, AI algorithms can process large datasets in real-time, enabling companies to respond swiftly to changing conditions. For instance, predictive analytics can forecast demand more accurately, allowing producers to adjust their operations accordingly. This shift towards data-driven decision-making is essential for meeting the growing demands of consumers for quality and sustainability in food products.

Key Takeaways

- AI algorithms play a crucial role in optimizing food processing operations by improving efficiency and accuracy.

- Robotics in food processing benefit from AI technology by enhancing automation, precision, and speed.

- AI algorithms contribute to improving robotic efficiency in food processing by reducing waste, increasing productivity, and ensuring consistent quality.

- Examples of AI applications in food processing robotics include sorting, grading, packaging, and quality control tasks.

- Challenges and limitations of AI algorithms in food processing include high initial investment, technical complexity, and potential job displacement, while future trends focus on enhanced machine learning, predictive maintenance, and collaborative robotics.

The Role of AI in Robotics for Food Processing

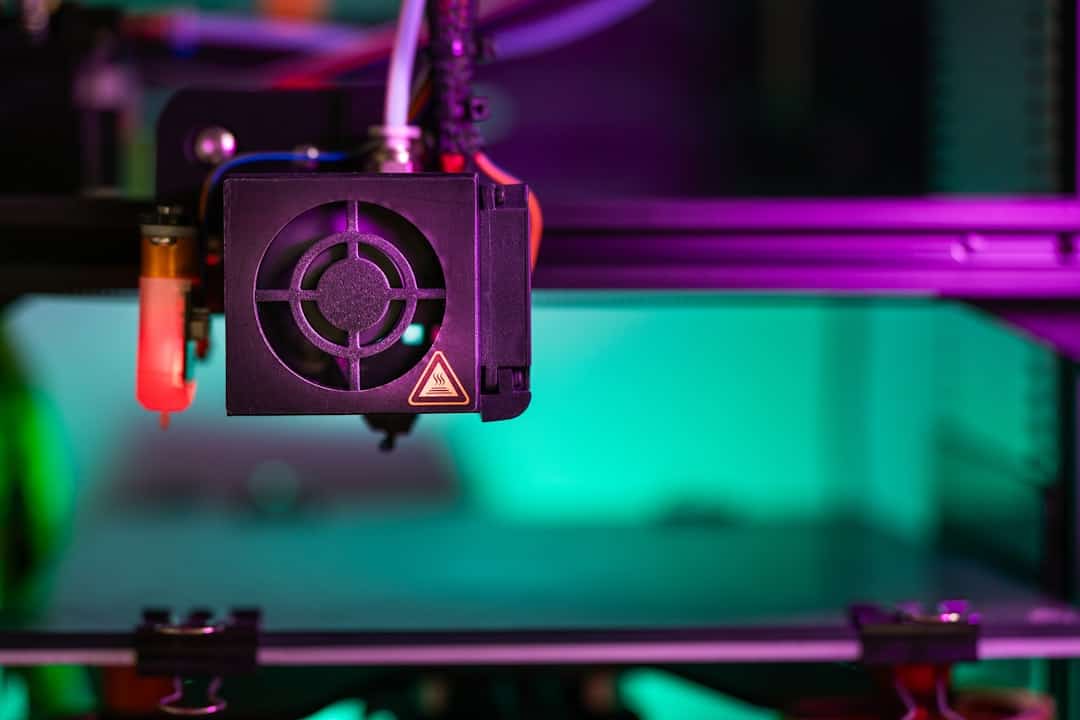

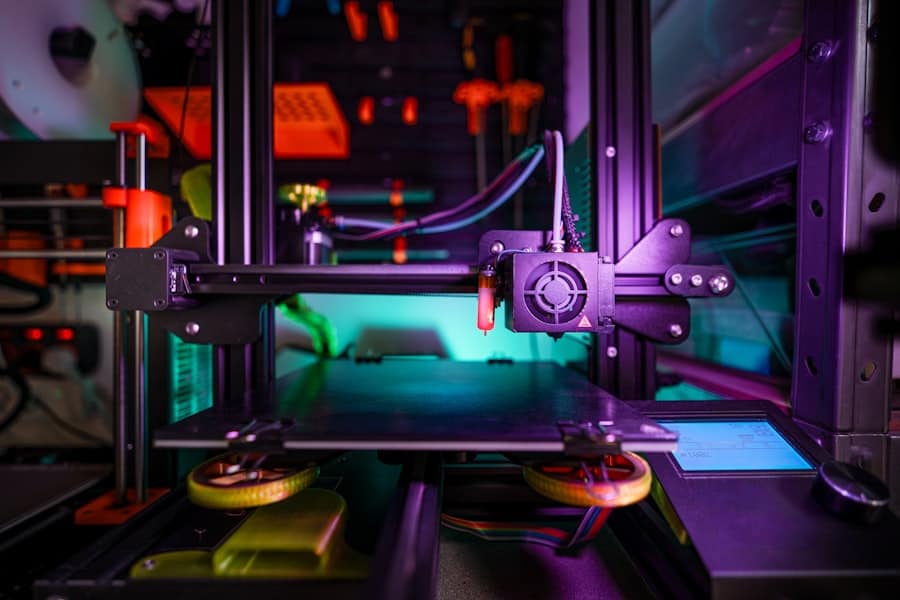

Robotics has become an integral part of modern food processing, with AI algorithms enhancing the capabilities of robotic systems. These robots are designed to perform repetitive tasks such as sorting, packaging, and quality inspection with high precision and speed. By incorporating AI, these robotic systems can adapt to variations in the production environment, improving their performance and reliability.

For example, AI-powered vision systems enable robots to identify defects in products or packaging materials, ensuring that only high-quality items reach consumers. Moreover, the role of AI in robotics extends beyond simple automation. Advanced machine learning techniques allow robots to learn from their experiences and improve their performance over time.

This capability is particularly valuable in dynamic environments where conditions can change rapidly. For instance, a robotic arm equipped with AI can adjust its grip strength based on the texture and weight of different food items, reducing the risk of damage during handling. This adaptability not only enhances efficiency but also contributes to better product quality and reduced waste.

Benefits of AI Algorithms in Improving Robotic Efficiency

The implementation of AI algorithms in food processing robotics offers numerous benefits that significantly enhance operational efficiency. One of the primary advantages is the ability to optimize workflows by analyzing data from various stages of production. For instance, AI can identify bottlenecks in the processing line and suggest adjustments to alleviate delays.

This real-time analysis allows companies to streamline their operations, reducing downtime and increasing throughput. Additionally, AI algorithms can improve predictive maintenance for robotic systems. By continuously monitoring the performance of machinery and analyzing historical data, AI can predict when a robot is likely to fail or require maintenance.

This proactive approach minimizes unexpected breakdowns and extends the lifespan of equipment. For example, a food processing plant that employs AI-driven predictive maintenance can schedule repairs during off-peak hours, ensuring that production remains uninterrupted while maintaining equipment efficiency.

Examples of AI Applications in Food Processing Robotics

Several companies have successfully implemented AI applications in their food processing robotics, showcasing the transformative potential of this technology. One notable example is the use of AI-powered robots in fruit harvesting. Companies like Agrobot have developed robotic systems that utilize computer vision and machine learning algorithms to identify ripe fruits and harvest them with precision.

These robots can operate autonomously in orchards, significantly reducing labor costs while increasing harvesting efficiency. Another example is the use of AI in packaging operations. Companies such as Soft Robotics have created robotic systems that employ AI algorithms to adapt their gripping mechanisms based on the shape and size of various food products.

This flexibility allows for efficient handling of diverse items without the need for extensive reprogramming or manual intervention. As a result, food processors can achieve higher levels of automation while maintaining product integrity during packaging.

Challenges and Limitations of AI Algorithms in Food Processing

Despite the numerous advantages of AI algorithms in food processing robotics, several challenges and limitations must be addressed for widespread adoption. One significant challenge is the need for high-quality data to train AI models effectively.

Ensuring that data is clean, relevant, and representative is crucial for developing robust AI algorithms that can perform reliably in real-world scenarios. Another limitation is the initial investment required for implementing AI technologies in food processing operations. While the long-term benefits may outweigh these costs, many smaller companies may struggle to justify the upfront expenditure on advanced robotics and AI systems.

Additionally, there may be resistance to change within organizations accustomed to traditional methods of operation.

Future Trends and Developments in AI for Food Processing Robotics

Smart Food Processing Systems

The integration of Internet of Things (IoT) devices with AI algorithms is an emerging trend, enabling the creation of smart food processing systems. By connecting various machines and sensors throughout the production line, companies can gather real-time data on equipment performance, environmental conditions, and product quality.

Enhanced Analytics and Decision-Making

This interconnectedness will facilitate more sophisticated analytics and decision-making capabilities. With access to real-time data, companies can optimize their production processes, reduce waste, and improve overall efficiency.

Human-Robot Collaboration

Advances in natural language processing (NLP) are likely to enhance human-robot collaboration in food processing environments. As robots become more capable of understanding human instructions and responding appropriately, they will be able to work alongside human operators more effectively, leading to increased productivity and improved safety.

Ethical and Safety Considerations in Implementing AI in Food Processing

As with any technological advancement, the implementation of AI algorithms in food processing raises ethical and safety considerations that must be carefully addressed. One primary concern is the potential impact on employment within the industry. While automation can lead to increased efficiency and reduced labor costs, it may also result in job displacement for workers performing repetitive tasks.

It is essential for companies to consider strategies for reskilling employees and creating new opportunities within the evolving landscape of food processing. Safety is another critical aspect that must be prioritized when integrating AI into food processing robotics. Ensuring that robotic systems operate safely alongside human workers is paramount to preventing accidents and injuries.

This includes implementing robust safety protocols, conducting regular training sessions for employees on working with robots, and designing machines with built-in safety features such as emergency stop buttons and collision detection systems.

The Impact of AI Algorithms on Robotic Efficiency in Food Processing

The impact of AI algorithms on robotic efficiency in food processing is profound and multifaceted. By enhancing automation capabilities through advanced machine learning techniques and data analytics, these technologies are transforming how food is produced and processed. The ability to optimize workflows, improve predictive maintenance, and adapt to changing conditions has made AI-powered robotics indispensable tools for modern food manufacturers.

As the industry continues to evolve, addressing challenges related to data quality, investment costs, and ethical considerations will be crucial for maximizing the benefits of AI in food processing robotics. The future holds exciting possibilities as innovations such as IoT integration and improved human-robot collaboration pave the way for smarter, safer, and more efficient food production systems. The journey towards fully realizing the potential of AI algorithms in this sector will undoubtedly shape the future landscape of food processing for years to come.

If you are interested in the latest advancements in technology, you may also want to check out this article on the best tech products to look out for in 2023. Just like how AI algorithms are improving robotic efficiency in food processing, these upcoming tech products are sure to revolutionize various industries and enhance productivity.

FAQs

What are AI algorithms in the context of food processing robotics?

AI algorithms in food processing robotics refer to the use of artificial intelligence to improve the efficiency and performance of robotic systems in the food processing industry. These algorithms enable robots to make autonomous decisions, learn from data, and adapt to changing conditions in order to optimize processes such as sorting, packaging, and quality control.

How do AI algorithms improve robotic efficiency in food processing?

AI algorithms improve robotic efficiency in food processing by enabling robots to perform tasks with greater speed, accuracy, and consistency. These algorithms can analyze large amounts of data to identify patterns and optimize processes, as well as make real-time adjustments to improve performance and reduce waste.

What are some specific applications of AI algorithms in food processing robotics?

Some specific applications of AI algorithms in food processing robotics include quality inspection, sorting and grading of products, packaging optimization, predictive maintenance, and autonomous navigation within processing facilities. These applications help to streamline operations, reduce labor costs, and improve overall product quality.

What are the benefits of using AI algorithms in food processing robotics?

The benefits of using AI algorithms in food processing robotics include increased productivity, improved product quality, reduced waste, lower operating costs, and enhanced worker safety. By leveraging AI algorithms, food processing companies can gain a competitive edge in the market and meet the growing demand for efficient and sustainable production methods.

Are there any challenges or limitations associated with the use of AI algorithms in food processing robotics?

Some challenges and limitations associated with the use of AI algorithms in food processing robotics include the initial investment in technology and training, potential job displacement for human workers, and the need to ensure the security and reliability of AI systems. Additionally, integrating AI algorithms into existing robotic systems may require careful planning and coordination to ensure seamless operation.