The advent of 3D printing technology has revolutionized various industries on Earth, and its potential applications in space construction are equally transformative. As humanity sets its sights on long-term habitation beyond our planet, the need for efficient, sustainable, and innovative construction methods becomes paramount. Traditional construction techniques, which rely heavily on transporting materials from Earth, are not feasible for extraterrestrial environments due to the immense costs and logistical challenges involved.

3D printing offers a solution by enabling the creation of structures using in-situ resources, thereby reducing the need for extensive supply chains and minimizing waste.

This method not only allows for the rapid prototyping of habitats and other essential infrastructure but also facilitates the customization of designs to meet specific environmental challenges.

As missions to the Moon, Mars, and beyond become more ambitious, the integration of 3D printing into space architecture is poised to play a critical role in establishing sustainable human presence in outer space.

Key Takeaways

- 3D printing in space construction is a revolutionary technology that allows for on-demand manufacturing of tools, parts, and even entire structures in the harsh environment of space.

- The benefits of 3D printing for space construction include reduced cost and time, increased flexibility in design, and the ability to utilize local resources such as lunar or Martian regolith.

- Challenges of 3D printing in space construction include the need for reliable and efficient printing technology, the development of suitable materials for the space environment, and the impact of microgravity on the printing process.

- Current applications of 3D printing in space construction include the production of spare parts on the International Space Station and the development of habitat prototypes for future lunar or Martian missions.

- The future potential of 3D printing in space construction is vast, with possibilities ranging from building large-scale structures on other planets to creating customized tools and equipment for astronauts on long-duration missions.

Benefits of 3D Printing for Space Construction

One of the most significant advantages of 3D printing in space construction is its ability to utilize local materials, a concept known as in-situ resource utilization (ISRU). By leveraging materials found on celestial bodies, such as lunar regolith or Martian soil, 3D printing can drastically reduce the amount of material that needs to be transported from Earth. This not only cuts costs but also minimizes the environmental impact associated with launching heavy payloads into space.

For instance, NASA’s Artemis program aims to use lunar regolith to create building materials for habitats on the Moon, showcasing the practical application of ISRU. Additionally, 3D printing allows for unprecedented design flexibility. Architects and engineers can create complex geometries that would be impossible or prohibitively expensive to achieve with traditional construction methods.

This capability is particularly beneficial in the harsh environments of space, where structures must withstand extreme temperatures, radiation, and micrometeorite impacts. The ability to rapidly iterate designs through digital modeling and printing means that solutions can be tailored specifically to the unique challenges posed by extraterrestrial environments.

Challenges of 3D Printing in Space Construction

Despite its numerous advantages, 3D printing in space construction is not without its challenges. One of the primary obstacles is the development of suitable materials that can withstand the extreme conditions of space. Materials must not only be strong and durable but also lightweight and resistant to radiation.

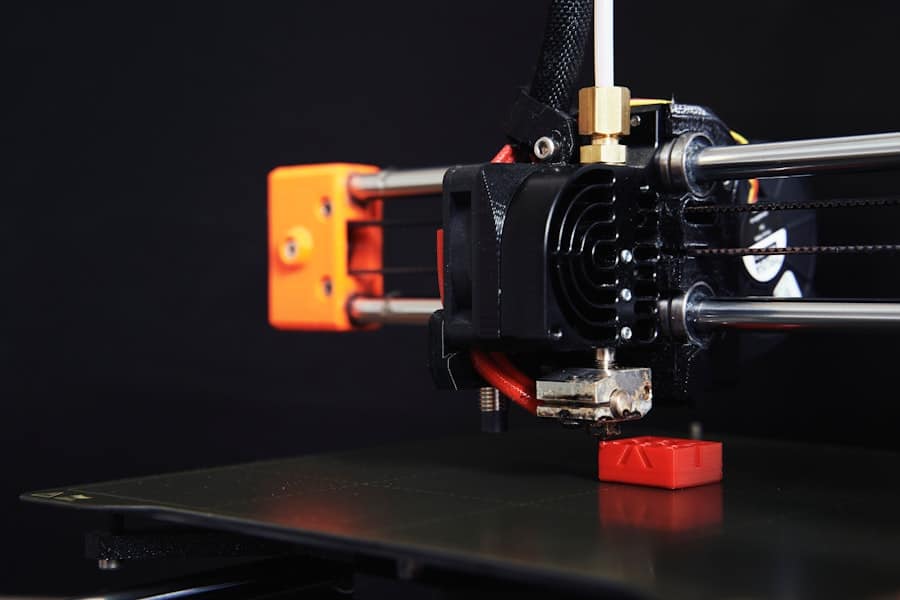

Current research is focused on creating composites that can endure these harsh conditions while still being amenable to 3D printing processes. For example, researchers are exploring the use of polymers infused with carbon nanotubes to enhance strength and thermal stability. Another significant challenge is the reliability and precision of 3D printing technology in microgravity environments.

The absence of gravity can affect the way materials behave during the printing process, leading to potential defects in the final product. Ensuring that 3D printers can operate effectively in such conditions requires extensive testing and adaptation of existing technologies. Moreover, the logistics of transporting and maintaining 3D printers on distant celestial bodies present additional hurdles that must be addressed before widespread implementation can occur.

Current Applications of 3D Printing in Space Construction

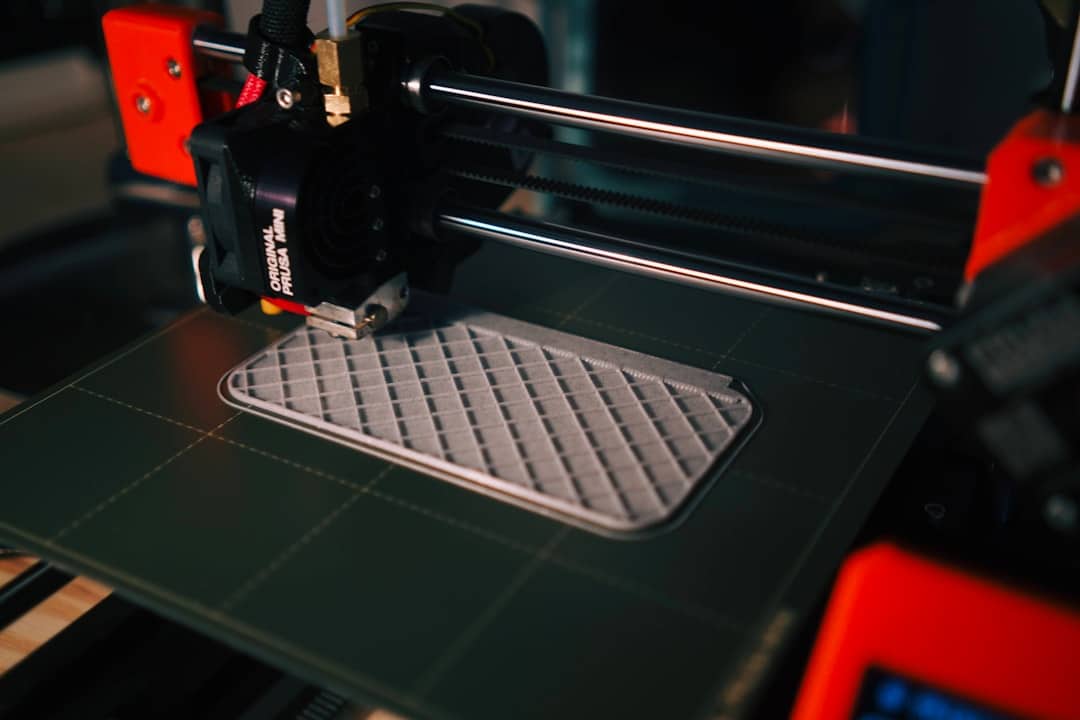

Currently, several organizations are actively exploring and implementing 3D printing technologies for space construction. NASA has been at the forefront of this initiative, conducting experiments aboard the International Space Station (ISS) to assess the feasibility of 3D printing components in microgravity. One notable project is the “Made In Space” initiative, which successfully demonstrated the ability to print tools and components on the ISS using a commercial 3D printer.

In addition to NASA, private companies like ICON and Relativity Space are making strides in this field. ICON has developed a concrete 3D printer called Vulcan that is designed for terrestrial applications but has potential implications for lunar construction as well.

Meanwhile, Relativity Space is pioneering a unique approach by using 3D printing to manufacture entire rockets, significantly reducing production time and costs. These advancements illustrate how both governmental and private entities are recognizing the importance of integrating 3D printing into their space exploration strategies.

Future Potential of 3D Printing in Space Construction

The future potential of 3D printing in space construction is vast and multifaceted. As technology continues to advance, we can expect to see more sophisticated printers capable of utilizing a wider range of materials, including metals and composites that are currently difficult to work with in space environments. The development of autonomous 3D printing systems could further enhance efficiency by allowing machines to construct habitats without direct human intervention, which is particularly valuable during long-duration missions where crew safety is paramount.

Moreover, as international collaboration in space exploration increases, so too will opportunities for shared research and development in 3D printing technologies. Collaborative efforts could lead to standardized practices and materials that facilitate construction across different celestial bodies. For instance, a consortium of nations working together on lunar bases could share insights gained from their respective 3D printing projects, accelerating progress and innovation in this critical area.

3D Printing Materials for Space Construction

The selection of materials for 3D printing in space construction is a critical factor that influences both performance and feasibility. Traditional materials like plastics may not provide the necessary strength or durability required for structures exposed to harsh space conditions. Therefore, researchers are investigating alternative materials that can be sourced from extraterrestrial environments or engineered specifically for space applications.

Lunar regolith is one promising material that has garnered significant attention due to its abundance on the Moon’s surface. Studies have shown that regolith can be processed into a form suitable for 3D printing, allowing for the creation of habitats that blend seamlessly with the lunar landscape. Similarly, Martian soil could be utilized for constructing bases on Mars, reducing the need for transporting building materials from Earth.

Additionally, advancements in metal alloys and composites are being explored to create stronger structures capable of withstanding extreme temperatures and radiation exposure.

Collaboration in 3D Printing for Space Construction

Collaboration among various stakeholders is essential for advancing 3D printing technologies in space construction. Government agencies like NASA and ESA (European Space Agency) are partnering with private companies and academic institutions to pool resources and expertise. These collaborations foster innovation by combining cutting-edge research with practical applications, ultimately leading to more effective solutions for space construction challenges.

For example, NASA’s partnership with Made In Space has resulted in significant advancements in additive manufacturing technologies tailored for microgravity environments. Similarly, initiatives like the Lunar Gateway project involve multiple international partners working together to develop infrastructure that will support future lunar missions. By sharing knowledge and resources, these collaborations not only enhance technological capabilities but also promote a unified approach to addressing the complexities of building in space.

The Role of 3D Printing in the Future of Space Construction

As humanity embarks on an era of exploration beyond Earth, 3D printing stands out as a pivotal technology that will shape the future of space construction. Its ability to utilize local resources, coupled with design flexibility and rapid prototyping capabilities, positions it as an essential tool for establishing sustainable habitats on other celestial bodies. While challenges remain—ranging from material development to operational reliability—the ongoing research and collaboration among various stakeholders indicate a promising trajectory.

The integration of 3D printing into space construction not only holds potential for building habitats but also extends to creating essential infrastructure such as landing pads, research facilities, and even spacecraft components. As we continue to push the boundaries of exploration, embracing innovative technologies like 3D printing will be crucial in ensuring that humanity can thrive beyond our home planet. The journey toward establishing a permanent presence on the Moon or Mars will undoubtedly be influenced by how effectively we harness this transformative technology in our quest for knowledge and discovery among the stars.

In the rapidly evolving field of space exploration, 3D printing is playing a pivotal role in supporting construction efforts beyond Earth. This innovative technology is not only revolutionizing how structures are built in space but also paving the way for sustainable living on other planets. For those interested in the broader implications of technological advancements, an article on CNET’s tracking of the latest consumer technology breakthroughs provides a comprehensive overview of how cutting-edge technologies are shaping various sectors, including space exploration. This resource offers valuable insights into the intersection of technology and its applications in both terrestrial and extraterrestrial environments.

FAQs

What is 3D printing in the context of construction in space?

3D printing in the context of construction in space refers to the use of additive manufacturing technology to create structures, tools, and other necessary items for construction projects in space.

How is 3D printing supporting construction in space?

3D printing is supporting construction in space by enabling the on-demand production of construction materials, tools, and components, reducing the need to transport pre-fabricated materials from Earth.

What are the benefits of using 3D printing for construction in space?

The benefits of using 3D printing for construction in space include reduced reliance on Earth-based supply chains, the ability to create complex and customized structures, and the potential for cost savings and increased efficiency.

What are some examples of 3D printing being used in construction projects in space?

Some examples of 3D printing being used in construction projects in space include the creation of habitat structures, tools, and spare parts for space missions and the development of technologies for in-situ resource utilization on other celestial bodies.

What are the challenges of using 3D printing for construction in space?

Challenges of using 3D printing for construction in space include the need to develop and test materials that can withstand the harsh conditions of space, the limitations of current 3D printing technology in terms of scale and speed, and the integration of 3D printing processes into existing space construction workflows.