Traditional manufacturing processes have long been associated with significant environmental consequences. These methods often rely on the extraction and use of non-renewable resources, leading to depletion of natural reserves. The production processes typically involve high energy consumption, which contributes to greenhouse gas emissions. Factories emit pollutants into the air and water, affecting local ecosystems and human health. Additionally, traditional manufacturing often generates substantial waste, as materials are cut, shaped, and assembled, leaving behind scraps that may not be recyclable.

The transportation of raw materials and finished products further exacerbates the environmental footprint of traditional manufacturing. The logistics involved in moving goods across long distances contribute to carbon emissions, while the packaging materials used to protect products during transit often end up in landfills. As global demand for manufactured goods continues to rise, the cumulative impact of these practices poses a significant challenge to sustainability efforts. Addressing these issues is crucial for mitigating climate change and promoting a more sustainable future.

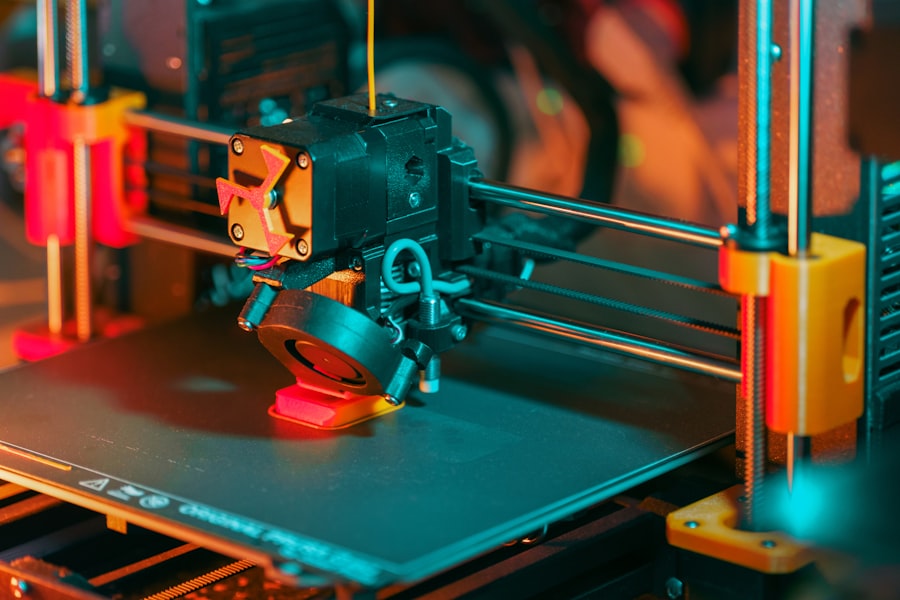

The rise of 3D printing with sustainable materials is not only revolutionizing manufacturing but also reshaping our approach to environmental responsibility in production processes. For a deeper understanding of how technology is influencing various industries, you can read the article on Recode, which explores the latest advancements in tech and their implications for the future. Check it out here: Recode Technology News.

Key Takeaways

- Traditional manufacturing has significant environmental impacts, including high waste and resource consumption.

- 3D printing with sustainable materials is emerging as an eco-friendly alternative in manufacturing.

- Using sustainable materials in 3D printing reduces waste and enhances design flexibility.

- Despite benefits, challenges like material limitations and cost remain in sustainable 3D printing.

- Successful case studies highlight the promising future of sustainable 3D printing in industry.

The Rise of 3D Printing with Sustainable Materials

In recent years, 3D printing has emerged as a transformative technology in the manufacturing sector, offering an alternative to traditional methods. This additive manufacturing process allows for the creation of objects layer by layer, using digital models. One of the most promising aspects of 3D printing is its potential to utilize sustainable materials, which can significantly reduce the environmental impact associated with production. As awareness of environmental issues grows, manufacturers are increasingly exploring options that align with sustainability goals.

The development of sustainable materials for 3D printing has gained momentum, with innovations in bioplastics, recycled plastics, and other eco-friendly substances. These materials not only reduce reliance on fossil fuels but also minimize waste generation during production. As companies adopt 3D printing technologies, they are finding ways to integrate these sustainable materials into their processes, leading to a more responsible approach to manufacturing. This shift represents a significant step toward reducing the overall ecological footprint of production activities.

Advantages of 3D Printing with Sustainable Materials

One of the primary advantages of 3D printing with sustainable materials is the reduction in material waste. Traditional manufacturing often involves subtractive processes that cut away excess material, resulting in significant scrap. In contrast, 3D printing is an additive process that builds objects layer by layer, using only the material necessary for the final product. This efficiency not only conserves resources but also lowers production costs over time.

Additionally, 3D printing allows for greater design flexibility compared to traditional methods. Designers can create complex geometries and customized products without the constraints imposed by conventional manufacturing techniques. This capability enables companies to produce items tailored to specific customer needs while minimizing excess inventory. The ability to rapidly prototype and iterate designs further enhances innovation, allowing businesses to respond quickly to market demands while maintaining a focus on sustainability.

The Role of Sustainable Materials in Reducing Waste

Sustainable materials play a crucial role in minimizing waste throughout the manufacturing process. By utilizing biodegradable or recyclable materials, manufacturers can significantly decrease the amount of waste generated at the end of a product’s life cycle. For instance, bioplastics derived from renewable resources can break down naturally in composting environments, reducing landfill contributions and pollution.

Moreover, the use of recycled materials in 3D printing helps close the loop on resource consumption. By repurposing plastics and other materials that would otherwise be discarded, manufacturers can create new products without depleting virgin resources. This circular economy approach not only conserves natural resources but also reduces energy consumption associated with material extraction and processing. As more companies adopt sustainable materials in their 3D printing processes, the potential for waste reduction becomes increasingly significant.

The rise of 3D printing with sustainable materials is revolutionizing the manufacturing industry, offering innovative solutions that reduce waste and promote eco-friendly practices. For those interested in exploring how technology is reshaping various sectors, a related article discusses the best tablet for on-stage lyrics, highlighting the intersection of technology and performance. You can read more about it here. This synergy between sustainable manufacturing and advanced technology showcases the potential for a greener future in multiple fields.

Sustainable Materials and Design Flexibility

| Metric | Traditional Manufacturing | 3D Printing with Sustainable Materials | Impact |

|---|---|---|---|

| Material Waste | Up to 90% | Less than 10% | Significant reduction in waste generation |

| Energy Consumption | High (due to mass production and machining) | Lower (additive process uses less energy) | Reduced carbon footprint |

| Production Time | Weeks to months | Hours to days | Faster prototyping and production cycles |

| Material Types | Primarily non-renewable plastics and metals | Biodegradable plastics, recycled composites, bio-based resins | Promotes circular economy and sustainability |

| Customization | Limited and costly | Highly flexible and cost-effective | Enables personalized manufacturing |

| Supply Chain Impact | Complex, global logistics | Localized production possible | Reduces transportation emissions and delays |

The integration of sustainable materials into 3D printing processes enhances design flexibility in several ways. Designers can experiment with various materials that offer different properties, such as strength, flexibility, and thermal resistance. This versatility allows for the creation of innovative products that meet specific performance criteria while adhering to sustainability principles.

Furthermore, 3D printing enables rapid prototyping, allowing designers to test and refine their ideas quickly. This iterative process encourages experimentation with sustainable materials that may not have been feasible in traditional manufacturing due to cost or technical limitations. As a result, companies can develop unique solutions that address both functional requirements and environmental concerns, fostering a culture of innovation within the industry.

Challenges and Limitations of 3D Printing with Sustainable Materials

Despite its advantages, 3D printing with sustainable materials is not without challenges. One significant limitation is the current availability and performance of these materials compared to traditional options. While advancements have been made in developing sustainable alternatives, some may not yet match the mechanical properties or durability required for certain applications. This discrepancy can hinder widespread adoption in industries where performance is critical.

Additionally, the cost of sustainable materials can be higher than that of conventional plastics or metals. This price difference may deter some manufacturers from making the switch to more eco-friendly options, particularly in price-sensitive markets. Furthermore, the infrastructure for recycling and processing these materials may not be fully developed in all regions, limiting their accessibility and usability. Addressing these challenges will be essential for maximizing the potential of sustainable 3D printing in manufacturing.

The Future of Sustainable 3D Printing in Manufacturing

The future of sustainable 3D printing in manufacturing appears promising as technological advancements continue to emerge. Ongoing research into new sustainable materials is likely to yield innovative solutions that enhance performance while minimizing environmental impact.

As industries increasingly prioritize sustainability, there will be greater demand for eco-friendly alternatives that align with corporate social responsibility goals.

Moreover, as consumer awareness regarding environmental issues grows, companies may find competitive advantages in adopting sustainable practices. This shift could drive investment in research and development focused on improving the efficiency and effectiveness of sustainable 3D printing technologies. Collaborative efforts among manufacturers, researchers, and policymakers will be crucial in creating a supportive ecosystem that fosters innovation and accelerates the transition toward more sustainable manufacturing practices.

Case Studies of Successful Implementation of Sustainable 3D Printing

Several companies have successfully implemented sustainable 3D printing practices, demonstrating the viability of this approach in various industries. For instance, a leading automotive manufacturer has begun using recycled plastics in its production processes for interior components. By integrating these materials into their supply chain, they have reduced their reliance on virgin resources while maintaining product quality.

Another example can be found in the fashion industry, where designers are utilizing biodegradable filaments for creating custom footwear and accessories through 3D printing. This approach not only reduces waste but also allows for unique designs tailored to individual customer preferences. These case studies illustrate how sustainable 3D printing can be effectively integrated into diverse sectors, paving the way for broader adoption and innovation in environmentally responsible manufacturing practices.

In conclusion, while traditional manufacturing has long been associated with environmental challenges, the rise of 3D printing with sustainable materials offers a promising alternative. By reducing waste, enhancing design flexibility, and addressing sustainability concerns, this technology has the potential to reshape manufacturing practices for a more sustainable future. However, overcoming existing challenges will require continued investment in research and collaboration across industries to fully realize its benefits.

FAQs

What are sustainable materials used in 3D printing?

Sustainable materials for 3D printing include biodegradable plastics like PLA (polylactic acid), recycled filaments made from plastic waste, bio-based resins, and composites that incorporate natural fibers. These materials reduce environmental impact compared to traditional petroleum-based plastics.

How does 3D printing with sustainable materials benefit manufacturing?

Using sustainable materials in 3D printing reduces waste, lowers carbon emissions, and minimizes reliance on non-renewable resources. It also enables on-demand production, which decreases inventory and transportation needs, contributing to a more eco-friendly manufacturing process.

Are sustainable 3D printing materials as strong and reliable as conventional materials?

Many sustainable 3D printing materials offer comparable strength and durability to traditional plastics, though performance can vary depending on the specific material and application. Advances in material science continue to improve the mechanical properties of sustainable filaments and resins.

What industries are adopting 3D printing with sustainable materials?

Industries such as automotive, aerospace, consumer goods, healthcare, and fashion are increasingly adopting sustainable 3D printing materials to create prototypes, functional parts, and customized products while reducing environmental impact.

Does 3D printing with sustainable materials reduce manufacturing costs?

While sustainable materials can sometimes be more expensive upfront, 3D printing reduces material waste and enables localized production, which can lower overall costs. Additionally, the environmental benefits may lead to long-term savings through improved efficiency and compliance with regulations.