Intelligent robotics represents a fascinating intersection of engineering, computer science, and cognitive psychology, where machines are designed not only to perform tasks but also to learn and adapt to their environments. At its core, intelligent robotics involves the integration of advanced algorithms, sensors, and actuators that enable robots to perceive their surroundings, make decisions, and execute actions autonomously. This field has evolved significantly over the past few decades, moving from simple mechanized systems to sophisticated entities capable of complex interactions with both their environment and human operators.

The essence of intelligent robotics lies in its ability to mimic human-like cognitive functions, such as perception, reasoning, and problem-solving, which allows these machines to operate in dynamic and unpredictable settings. The development of intelligent robotics is driven by a multitude of factors, including the need for increased efficiency in various industries, the desire for enhanced safety in hazardous environments, and the quest for improved quality in manufacturing processes. As technology advances, robots are becoming more adept at handling intricate tasks that were once thought to be the exclusive domain of humans.

This evolution is not merely about creating machines that can perform repetitive tasks; it is about designing systems that can learn from experience, adapt to new challenges, and collaborate with human workers. The implications of this shift are profound, as intelligent robots are poised to revolutionize industries ranging from manufacturing and logistics to healthcare and agriculture.

Key Takeaways

- Intelligent robotics refers to the use of artificial intelligence and advanced sensors to enable robots to perform complex tasks and adapt to changing environments.

- Industrial automation has evolved from simple mechanization to the use of robotics and AI to streamline manufacturing processes and improve efficiency.

- Artificial intelligence plays a crucial role in robotics by enabling machines to learn from experience, make decisions, and perform tasks with minimal human intervention.

- Intelligent robotics in industrial automation offers advantages such as increased productivity, improved quality, and enhanced worker safety.

- The adoption of intelligent robotics in industrial automation has the potential to impact the labor market by creating new job opportunities and displacing some traditional roles.

The Evolution of Industrial Automation

The Early Days of Industrial Automation

The journey of industrial automation began in the early 20th century with the introduction of mechanized production lines, which significantly increased efficiency and reduced labor costs. Over the decades, this initial wave of automation evolved into more sophisticated systems that incorporated programmable logic controllers (PLCs) and computer numerical control (CNC) machines. These advancements allowed for greater precision and flexibility in manufacturing processes, enabling companies to produce a wider variety of products with less downtime.

The Emergence of Industry 4.0

As industries embraced these technologies, the concept of automation expanded beyond mere mechanization to include the integration of information technology, leading to what we now refer to as Industry 4.0—a paradigm characterized by smart factories and interconnected systems. In recent years, the evolution of industrial automation has been further accelerated by the advent of intelligent robotics. These advanced machines are not only capable of performing repetitive tasks but also possess the ability to learn from their experiences and adapt to changing conditions on the factory floor.

The Role of Artificial Intelligence and Sensor Technology

This shift has been fueled by advancements in artificial intelligence (AI), machine learning, and sensor technology, which have collectively transformed the landscape of industrial automation. As a result, businesses are increasingly adopting intelligent robotic systems to enhance productivity, reduce operational costs, and improve overall product quality. The integration of these technologies marks a significant milestone in the evolution of industrial automation, paving the way for a future where human workers and intelligent robots collaborate seamlessly.

The Role of Artificial Intelligence in Robotics

Artificial intelligence plays a pivotal role in the development and functionality of intelligent robotics. By enabling machines to process vast amounts of data and learn from their interactions with the environment, AI enhances a robot’s ability to perform complex tasks with a level of autonomy that was previously unattainable. Machine learning algorithms allow robots to recognize patterns, make predictions, and improve their performance over time based on feedback from their surroundings.

This capability is particularly valuable in dynamic environments where conditions can change rapidly, requiring robots to adapt their strategies in real-time. For instance, in manufacturing settings, AI-powered robots can adjust their operations based on variations in product specifications or unexpected disruptions in the supply chain. Moreover, AI facilitates advanced decision-making processes within robotic systems.

By leveraging techniques such as natural language processing and computer vision, robots can interpret human commands and understand visual cues from their environment. This not only enhances their ability to work alongside human operators but also opens up new possibilities for collaborative robotics—where humans and machines work together towards common goals. The integration of AI into robotics is transforming industries by enabling more efficient workflows, reducing errors, and increasing overall productivity.

As AI continues to evolve, its role in robotics will likely expand further, leading to even more sophisticated systems capable of tackling increasingly complex challenges across various sectors.

Advantages of Intelligent Robotics in Industrial Automation

The advantages of intelligent robotics in industrial automation are manifold and have far-reaching implications for businesses across various sectors. One of the most significant benefits is the enhancement of operational efficiency. Intelligent robots can work tirelessly around the clock without fatigue or breaks, leading to increased production rates and reduced lead times.

Their ability to perform tasks with high precision minimizes errors and waste, resulting in improved product quality and lower costs. Furthermore, these robots can be programmed to handle a wide range of tasks—from assembly line work to quality control—allowing companies to adapt quickly to changing market demands without the need for extensive retraining or reconfiguration. In addition to efficiency gains, intelligent robotics also contribute to improved workplace safety.

Many industrial environments pose inherent risks to human workers, such as exposure to hazardous materials or dangerous machinery. By deploying intelligent robots in these settings, companies can mitigate these risks and create safer working conditions for their employees. Robots can take on dangerous tasks such as heavy lifting or working in extreme temperatures, thereby reducing the likelihood of workplace accidents and injuries.

This not only protects workers but also enhances overall morale and productivity within the organization. As businesses continue to recognize these advantages, the adoption of intelligent robotics is expected to accelerate, driving further innovation in industrial automation.

Impact on Labor and Job Market

The rise of intelligent robotics in industrial automation has sparked considerable debate regarding its impact on the labor market. On one hand, there are concerns that increased automation will lead to job displacement as machines take over tasks traditionally performed by human workers. This fear is particularly pronounced in sectors such as manufacturing and logistics, where repetitive tasks are increasingly being automated.

As companies invest in intelligent robotic systems that can operate more efficiently than human workers, there is a legitimate concern that many jobs may become obsolete, leading to unemployment and economic disruption. Conversely, it is essential to recognize that while some jobs may be lost due to automation, new opportunities are also likely to emerge as a result of technological advancements. The integration of intelligent robotics into industrial processes often necessitates a shift in workforce skills, creating demand for workers who can design, program, maintain, and operate these advanced systems.

Additionally, as businesses become more efficient through automation, they may experience growth that leads to job creation in other areas—such as research and development or customer service—where human skills remain indispensable. Ultimately, the impact on labor will depend on how society adapts to these changes and invests in workforce development initiatives that prepare workers for the jobs of the future.

Challenges and Limitations of Intelligent Robotics

**The High Cost of Implementing Intelligent Robotics**

The adoption of intelligent robotics in industrial automation is hindered by several challenges and limitations. One significant obstacle is the high initial cost associated with implementing advanced robotic systems. Although these technologies can lead to long-term savings through increased efficiency and reduced labor costs, the upfront investment required for purchasing and integrating intelligent robots can be prohibitive for many small- and medium-sized enterprises (SMEs).

**Ongoing Maintenance and Complexity of Intelligent Robotics**

In addition to the initial cost, ongoing maintenance and updates are necessary to ensure optimal performance, further complicating financial considerations for businesses looking to adopt these technologies. The complexity of programming and managing intelligent robotic systems is another challenge. While advancements in AI have made it easier for robots to learn from their environments, developing algorithms that enable effective decision-making remains a complex task requiring specialized knowledge.

**Ensuring Seamless Human-Robot Collaboration**

Furthermore, ensuring seamless collaboration between human workers and robots presents its own set of challenges. Effective communication protocols must be established to facilitate interaction between humans and machines. This requires careful consideration of the roles and responsibilities of both humans and robots, as well as the development of intuitive interfaces that enable humans to work effectively with robots.

**Addressing Challenges for Widespread Adoption**

As industries continue to explore the potential of intelligent robotics, addressing these challenges will be crucial for maximizing their benefits while minimizing disruptions. By overcoming the high cost, complexity, and collaboration challenges associated with intelligent robotics, businesses can unlock the full potential of these technologies and achieve significant improvements in efficiency, productivity, and competitiveness.

Future Trends in Intelligent Robotics and Industrial Automation

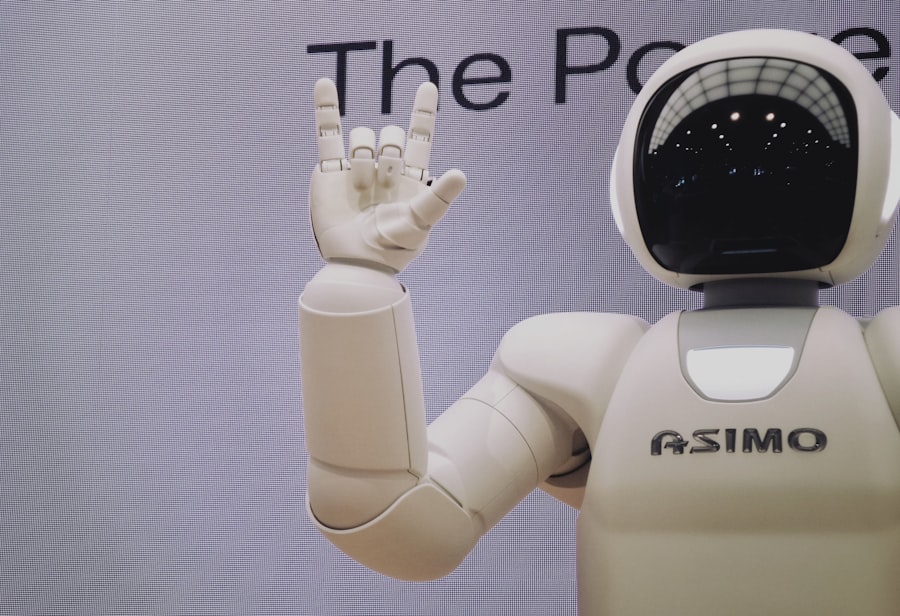

Looking ahead, several trends are poised to shape the future landscape of intelligent robotics and industrial automation. One notable trend is the increasing emphasis on collaborative robots—or cobots—that are designed specifically to work alongside human operators rather than replace them. These robots are equipped with advanced sensors and AI capabilities that allow them to safely interact with humans in shared workspaces.

As industries recognize the value of human-robot collaboration in enhancing productivity while maintaining a safe working environment, cobots are expected to become more prevalent across various sectors. Additionally, advancements in AI will continue to drive innovation within intelligent robotics. As machine learning algorithms become more sophisticated, robots will be able to perform increasingly complex tasks with greater autonomy.

This evolution will likely lead to the development of self-learning systems capable of adapting not only to their immediate environments but also to broader market trends and consumer preferences. Furthermore, as connectivity improves through technologies such as 5G and the Internet of Things (IoT), intelligent robots will be able to communicate with each other and share data in real-time—creating a more integrated and responsive industrial ecosystem. In conclusion, intelligent robotics represents a transformative force within industrial automation that promises significant benefits while also posing challenges that must be navigated thoughtfully.

As we move forward into an era defined by rapid technological advancement, understanding these dynamics will be essential for harnessing the full potential of intelligent robotics while ensuring a balanced approach that considers both economic growth and workforce development.

If you’re interested in the intersection of technology and automation, particularly how intelligent robotics is revolutionizing industries, you might also find value in exploring the capabilities of modern computing devices that support such innovations. A relevant resource is an article that reviews the best laptops for coding and programming. This guide provides insights into the top laptops that are well-suited for developers and programmers who are integral to designing and maintaining the software that drives intelligent robotic systems. Understanding the hardware that supports software development can give you a better appreciation of the backend tools powering industrial automation.

FAQs

What is intelligent robotics?

Intelligent robotics refers to the use of advanced technologies such as artificial intelligence, machine learning, and computer vision in the design and development of robotic systems. These technologies enable robots to perceive and interact with their environment, make decisions, and adapt to changing conditions.

How does intelligent robotics change industrial automation?

Intelligent robotics has the potential to revolutionize industrial automation by increasing efficiency, flexibility, and productivity. Robots equipped with intelligent capabilities can perform complex tasks with precision, adapt to new production requirements, and collaborate with human workers in a safe and efficient manner.

What are the benefits of intelligent robotics in industrial automation?

The benefits of intelligent robotics in industrial automation include improved quality and consistency of production, reduced operational costs, increased safety for workers, and the ability to handle a wider range of tasks and processes. Intelligent robotics also enables companies to respond more quickly to market demands and changes in production requirements.

What are some examples of intelligent robotics in industrial automation?

Examples of intelligent robotics in industrial automation include autonomous mobile robots for material handling, collaborative robots (cobots) that work alongside human workers, and robotic systems equipped with advanced vision systems for quality inspection and assembly tasks. Additionally, intelligent robotics is being used in the development of smart factories and flexible manufacturing systems.