The advent of smart robotics has revolutionized various sectors, particularly in enhancing workplace safety. Smart robotics refers to the integration of artificial intelligence (AI), machine learning, and advanced sensors into robotic systems, enabling them to perform tasks autonomously and interact intelligently with their environment. This technology is not merely about automating repetitive tasks; it encompasses a broader spectrum of capabilities, including real-time data analysis, decision-making, and adaptive learning.

As industries strive for greater efficiency and safety, the role of smart robotics becomes increasingly pivotal. In the context of workplace safety, smart robotics can significantly mitigate risks associated with hazardous tasks. By deploying robots in environments that pose threats to human workers—such as construction sites, chemical plants, and mining operations—companies can protect their workforce while maintaining productivity.

The evolution of these systems has been driven by advancements in sensor technology, AI algorithms, and connectivity, allowing robots to navigate complex environments and make informed decisions based on real-time data. As organizations recognize the potential of smart robotics, they are beginning to integrate these systems into their safety protocols, leading to a transformative shift in how work is conducted.

Key Takeaways

- Smart robotics refers to the use of advanced technology and artificial intelligence to create robots that can perform tasks with minimal human intervention.

- Smart robotics in the workplace can improve safety by taking on hazardous tasks, reducing the risk of accidents and injuries to human workers.

- Implementation of smart robotics in hazardous environments such as nuclear facilities and chemical plants can minimize human exposure to dangerous substances and environments.

- Training and education programs are essential for successful integration of smart robotics into the workplace, ensuring that workers are equipped to operate and interact with these advanced systems.

- Monitoring and maintenance of smart robotics systems is crucial for ensuring their continued safe and efficient operation, and preventing potential malfunctions or accidents.

Advantages of Smart Robotics in Workplace Safety

Reducing Risk through Task Automation

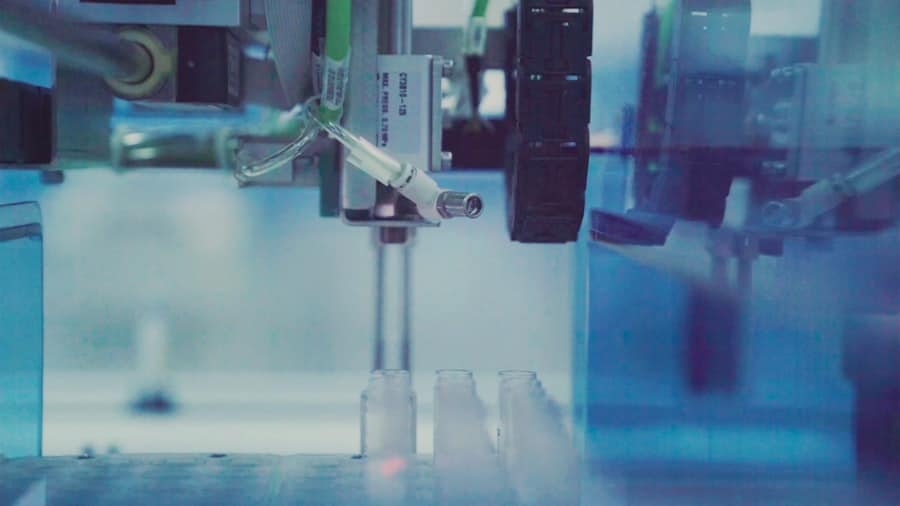

The use of drones for aerial inspections and robotic arms for lifting heavy objects exemplifies how smart robotics can take on roles that would otherwise be perilous for humans. By automating these tasks, smart robotics can minimize the risk of accidents and injuries, creating a safer work environment.

Enhancing Situational Awareness

Smart robotics can also enhance situational awareness through advanced sensor technologies. Equipped with cameras, LiDAR, and other sensing devices, these robots can monitor their surroundings and detect potential hazards in real time. This enables them to identify and respond to hazards promptly, preventing accidents and fostering a culture of safety within the organization.

Creating a Responsive and Adaptive Workplace Environment

By integrating smart robotics into safety protocols, companies can create a more responsive and adaptive workplace environment. Smart robots can identify hazards such as spills or obstructions on the floor and alert human workers or take corrective actions autonomously. This proactive approach to hazard detection not only prevents accidents but also promotes a culture of safety, leading to a safer and more efficient workplace.

Implementation of Smart Robotics in Hazardous Environments

The implementation of smart robotics in hazardous environments requires careful planning and consideration of various factors. First and foremost, organizations must conduct thorough risk assessments to identify specific tasks that can be safely delegated to robots. For instance, in chemical processing plants where exposure to toxic substances is a concern, robots can be utilized for monitoring equipment or conducting maintenance checks without putting human lives at risk.

This strategic deployment not only enhances safety but also ensures compliance with regulatory standards. Furthermore, the integration process involves selecting the right technology that aligns with the operational needs of the organization. Companies must evaluate different robotic systems based on their capabilities, such as mobility, dexterity, and sensory perception.

For example, mobile robots equipped with advanced navigation systems can traverse uneven terrain in mining operations, while collaborative robots (cobots) can work alongside human operators in manufacturing settings. The choice of technology should also consider the existing infrastructure and how seamlessly the new systems can be integrated into current workflows.

Training and Education for Smart Robotics Integration

As organizations adopt smart robotics, training and education become critical components for successful integration. Employees must be equipped with the knowledge and skills necessary to work alongside these advanced systems effectively. This includes understanding how to operate robotic systems safely, interpret data generated by robots, and respond to alerts or anomalies detected by the technology.

Comprehensive training programs should encompass both theoretical knowledge and practical experience to ensure that workers are confident in their interactions with smart robotics. Moreover, fostering a culture of continuous learning is essential as technology evolves rapidly. Organizations should invest in ongoing education initiatives that keep employees updated on the latest advancements in smart robotics and their applications in workplace safety.

This could involve workshops, online courses, or partnerships with educational institutions specializing in robotics and automation. By prioritizing training and education, companies can empower their workforce to embrace technological changes while enhancing overall safety standards.

Monitoring and Maintenance of Smart Robotics Systems

The effectiveness of smart robotics in enhancing workplace safety hinges on robust monitoring and maintenance practices. Regular inspections and maintenance routines are essential to ensure that robotic systems operate at peak performance levels. Organizations must establish protocols for routine checks on hardware components, software updates, and sensor calibrations to prevent malfunctions that could compromise safety.

For instance, a malfunctioning sensor on a robotic arm could lead to incorrect movements, posing risks to nearby workers. Additionally, real-time monitoring systems can provide valuable insights into the performance of smart robotics. By leveraging data analytics and machine learning algorithms, organizations can predict potential failures before they occur.

Predictive maintenance strategies allow companies to address issues proactively rather than reactively, minimizing downtime and ensuring that robotic systems remain reliable in hazardous environments. This approach not only enhances safety but also contributes to operational efficiency by reducing unexpected disruptions.

Case Studies of Successful Smart Robotics Integration

Several organizations have successfully integrated smart robotics into their operations, showcasing the tangible benefits of this technology for workplace safety. One notable example is the use of autonomous drones in the oil and gas industry for pipeline inspections. Companies like BP have deployed drones equipped with thermal imaging cameras to monitor pipelines for leaks or structural integrity issues.

This approach not only reduces the need for human inspectors to enter potentially dangerous areas but also allows for more frequent inspections, leading to early detection of problems. Another compelling case study is found in the automotive manufacturing sector, where companies like Ford have implemented collaborative robots (cobots) on assembly lines. These cobots work alongside human workers to assist with repetitive tasks such as lifting heavy components or performing quality checks.

By sharing the workload with humans, cobots reduce physical strain on workers while maintaining high levels of productivity. The integration of these systems has resulted in fewer workplace injuries and a more efficient assembly process.

Future Trends and Developments in Smart Robotics for Workplace Safety

The future of smart robotics in workplace safety is poised for significant advancements driven by ongoing research and technological innovations. One emerging trend is the increased use of artificial intelligence to enhance decision-making capabilities within robotic systems. As AI algorithms become more sophisticated, robots will be able to analyze complex data sets and make real-time decisions that improve safety outcomes.

For instance, AI-powered robots could adapt their behavior based on changing environmental conditions or learn from past incidents to avoid similar situations in the future.

IoT-enabled sensors can provide continuous monitoring of environmental conditions, such as air quality or temperature fluctuations in hazardous areas.

When combined with robotic systems capable of responding autonomously to these changes, organizations can create a dynamic safety ecosystem that proactively addresses potential risks before they escalate into serious incidents.

Conclusion and Recommendations for Smart Robotics Implementation

To fully harness the potential of smart robotics for workplace safety, organizations must adopt a strategic approach to implementation. This includes conducting thorough assessments of existing workflows to identify areas where robotic systems can add value while enhancing safety protocols. Engaging employees throughout the integration process is crucial; their insights can inform decisions about which tasks are best suited for automation.

Furthermore, investing in training programs that equip employees with the necessary skills to work alongside smart robotics will foster a culture of collaboration between humans and machines. Organizations should also prioritize ongoing monitoring and maintenance practices to ensure that robotic systems operate reliably over time. By embracing these recommendations, companies can create safer workplaces while reaping the benefits of increased efficiency and productivity through smart robotics integration.

A related article to The Role of Smart Robotics in Enhancing Workplace Safety Standards is “NeuronWriter Review: The Best Content SEO Optimization Tool.” This article discusses how NeuronWriter can help businesses improve their online presence and reach a wider audience through optimized content. By utilizing tools like NeuronWriter, companies can enhance their digital marketing strategies and ultimately increase their visibility and profitability. To learn more about NeuronWriter, check out the article com/neuronwriter-review-the-best-content-seo-optimization-tool/’>here.

FAQs

What is smart robotics?

Smart robotics refers to the use of advanced technologies such as artificial intelligence, machine learning, and sensors to create robots that can perform complex tasks with minimal human intervention.

How can smart robotics enhance workplace safety standards?

Smart robotics can enhance workplace safety standards by taking over dangerous or repetitive tasks, reducing the risk of injury to human workers. They can also be programmed to operate in hazardous environments, minimizing the exposure of humans to potential dangers.

What are some examples of smart robotics in the workplace?

Examples of smart robotics in the workplace include autonomous forklifts in warehouses, robotic arms in manufacturing plants, and drones for inspection and surveillance in industrial settings.

What are the benefits of using smart robotics for workplace safety?

The benefits of using smart robotics for workplace safety include improved efficiency, reduced human error, and decreased risk of workplace accidents. Additionally, smart robotics can help in monitoring and enforcing safety protocols and standards.

Are there any challenges associated with implementing smart robotics in the workplace?

Challenges associated with implementing smart robotics in the workplace include the initial cost of investment, the need for specialized training for employees, and potential job displacement for workers whose tasks are automated. Additionally, ensuring the cybersecurity of smart robotics systems is a concern.