Semiconductor manufacturing is a cornerstone of modern technology, underpinning everything from smartphones to supercomputers. The process involves the intricate fabrication of semiconductor devices, which are essential for controlling electrical currents. This industry has evolved significantly over the decades, driven by the relentless demand for smaller, faster, and more efficient electronic components.

The manufacturing process itself is complex, involving multiple stages such as wafer fabrication, assembly, and testing. Each stage requires precision and control, as even the slightest deviation can lead to defects that compromise the functionality of the final product. The semiconductor industry is characterized by its rapid pace of innovation and technological advancement.

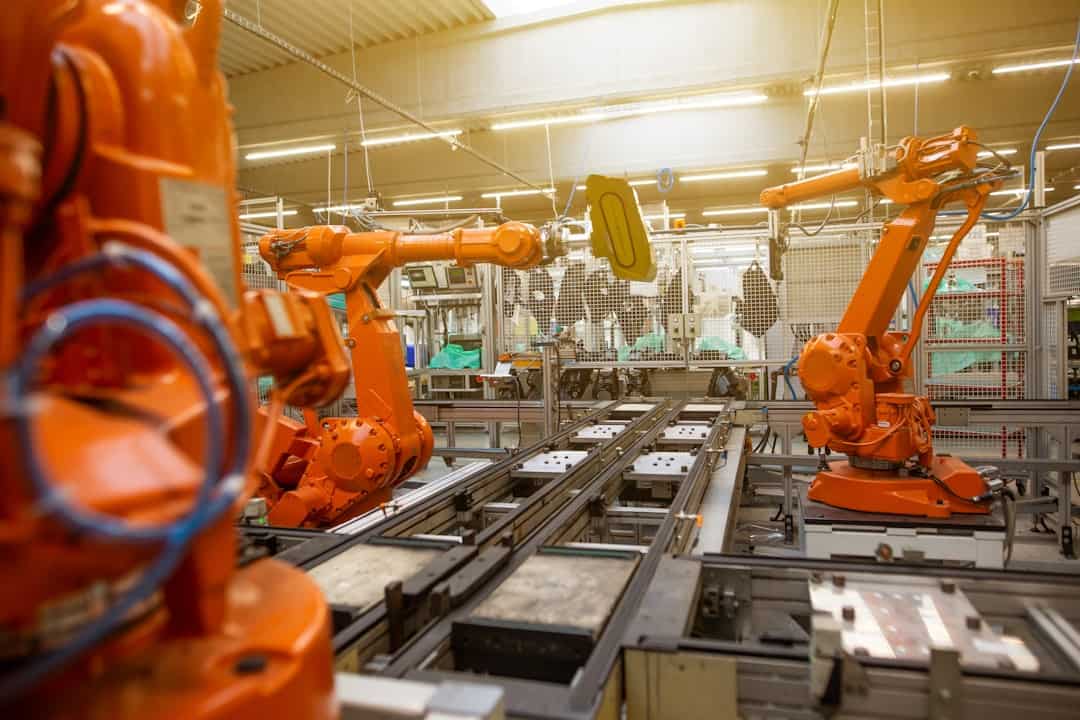

As consumer electronics continue to proliferate, the need for advanced semiconductor solutions has never been greater. This has led to the adoption of cutting-edge technologies, including robotics, which have transformed traditional manufacturing processes. Robotics in semiconductor manufacturing not only enhances efficiency but also improves accuracy and reduces the risk of contamination—critical factors in an industry where even microscopic impurities can lead to significant failures.

As we delve deeper into the evolution and impact of robotics in this field, it becomes clear that these technologies are not merely supplementary; they are integral to the future of semiconductor manufacturing.

Key Takeaways

- Semiconductor manufacturing involves the production of electronic components using semiconductor materials.

- Robotics in semiconductor manufacturing has evolved to improve efficiency, accuracy, and safety in the production process.

- Advantages of using robotics in semiconductor manufacturing include increased productivity, reduced human error, and improved quality control.

- Types of robotics used in semiconductor manufacturing include industrial robots, collaborative robots, and automated guided vehicles.

- Challenges and limitations of robotics in semiconductor manufacturing include high initial investment, complex programming, and potential job displacement.

The Evolution of Robotics in Semiconductor Manufacturing

The integration of robotics into semiconductor manufacturing can be traced back to the late 20th century when the industry began to recognize the potential benefits of automation. Initially, robots were employed for simple tasks such as material handling and assembly line operations. These early robotic systems were relatively basic, often limited in their capabilities and flexibility.

However, as semiconductor technology advanced and production demands increased, so too did the sophistication of robotic systems. The introduction of programmable logic controllers (PLCs) allowed for greater control over robotic movements and operations, paving the way for more complex applications. As the semiconductor industry faced challenges such as increasing production volumes and the need for higher precision, robotics evolved to meet these demands.

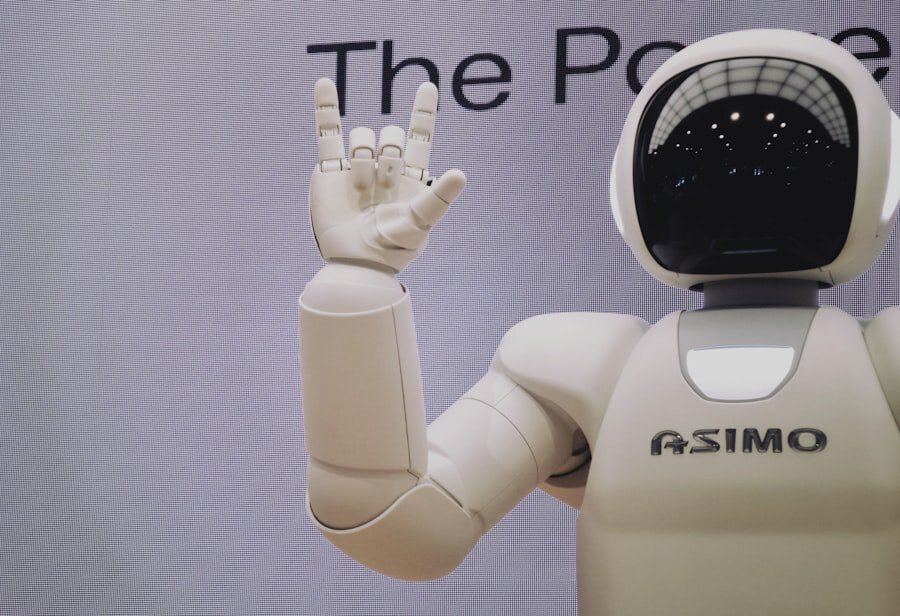

The development of collaborative robots, or cobots, marked a significant milestone in this evolution. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside human operators, enhancing productivity while ensuring safety. This shift not only improved operational efficiency but also allowed for more flexible manufacturing processes.

Today, robotics in semiconductor manufacturing encompasses a wide range of applications, from wafer handling and inspection to packaging and testing, reflecting the industry’s ongoing commitment to innovation.

Advantages of Using Robotics in Semiconductor Manufacturing

The advantages of incorporating robotics into semiconductor manufacturing are manifold. One of the most significant benefits is the enhancement of precision and accuracy in production processes. Robots can perform tasks with a level of consistency that far exceeds human capabilities.

For instance, in wafer fabrication, robots can handle delicate silicon wafers with extreme care, minimizing the risk of breakage or contamination. This precision is crucial in an industry where even minute defects can lead to substantial financial losses and compromised product performance. In addition to precision, robotics also contribute to increased efficiency and productivity.

Automated systems can operate continuously without fatigue, allowing for higher throughput rates compared to manual labor. This is particularly important in semiconductor manufacturing, where production cycles are often tightly scheduled to meet market demands. Furthermore, robots can be programmed to perform multiple tasks sequentially or simultaneously, optimizing workflow and reducing downtime.

The ability to quickly adapt to changing production requirements also enhances flexibility, enabling manufacturers to respond swiftly to shifts in consumer demand or technological advancements.

Types of Robotics Used in Semiconductor Manufacturing

The landscape of robotics in semiconductor manufacturing is diverse, encompassing various types of robotic systems tailored for specific applications. One prominent category is articulated robots, which feature multiple joints that allow for a wide range of motion. These robots are particularly effective for tasks requiring intricate movements, such as assembling components or performing precise inspections.

Their versatility makes them suitable for various stages of semiconductor production. Another important type is SCARA (Selective Compliance Assembly Robot Arm) robots, which excel in horizontal movements and are commonly used for assembly tasks. SCARA robots are known for their speed and accuracy, making them ideal for high-volume production environments where efficiency is paramount.

Additionally, delta robots—characterized by their parallel arm structure—are increasingly utilized for high-speed pick-and-place operations. These robots can rapidly move components from one location to another with minimal delay, significantly enhancing throughput. Moreover, specialized robotic systems such as wafer handling robots play a critical role in semiconductor manufacturing.

These robots are designed specifically for transporting silicon wafers between different processing stations while maintaining strict cleanliness standards. Their design minimizes the risk of contamination and damage during transport, which is vital in maintaining the integrity of semiconductor devices.

Challenges and Limitations of Robotics in Semiconductor Manufacturing

Despite the numerous advantages that robotics bring to semiconductor manufacturing, several challenges and limitations persist. One significant hurdle is the high initial investment required for implementing robotic systems. The cost of advanced robotic technology can be prohibitive for smaller manufacturers or those operating on tight budgets.

Additionally, integrating robotics into existing production lines may require substantial modifications to infrastructure and processes, further escalating costs. Another challenge lies in the complexity of programming and maintaining robotic systems. While modern robots are equipped with sophisticated software that allows for easy programming and operation, there remains a steep learning curve associated with their implementation.

Skilled personnel are needed not only to program these systems but also to troubleshoot issues that may arise during operation. This reliance on specialized knowledge can create bottlenecks if qualified staff are not readily available. Furthermore, while robotics enhance efficiency and precision, they cannot entirely replace human oversight in semiconductor manufacturing.

Certain tasks still require human intuition and decision-making capabilities that robots cannot replicate. For instance, quality control processes often benefit from human judgment when assessing product performance or identifying defects that may not be easily detectable by automated systems.

Future Trends in Robotics for Semiconductor Manufacturing

Artificial Intelligence and Machine Learning

One notable trend is the increasing adoption of artificial intelligence (AI) and machine learning algorithms within robotic systems. By leveraging AI capabilities, robots can analyze vast amounts of data generated during production processes to optimize operations further. This could lead to predictive maintenance strategies that minimize downtime by anticipating equipment failures before they occur.

Autonomous Mobile Robots

Another trend is the rise of autonomous mobile robots (AMRs) within semiconductor manufacturing facilities. These robots can navigate complex environments independently, transporting materials and components between different areas of a factory without human intervention. The integration of AMRs can streamline logistics and reduce manual labor requirements, allowing human workers to focus on more complex tasks that require critical thinking and creativity.

Advancements in Sensor Technology

Advancements in sensor technology will enhance the capabilities of robotic systems in semiconductor manufacturing. Improved sensors will enable robots to gather real-time data about their environment and adapt their actions accordingly.

Case Studies of Successful Implementation of Robotics in Semiconductor Manufacturing

Several companies have successfully integrated robotics into their semiconductor manufacturing processes, showcasing the transformative potential of these technologies. For instance, Intel has been at the forefront of adopting automation within its fabrication facilities. The company employs a range of robotic systems for wafer handling and inspection tasks, significantly improving efficiency while maintaining stringent quality standards.

By utilizing advanced robotics alongside AI-driven analytics, Intel has been able to optimize its production processes and reduce operational costs.

This automation has not only enhanced logistics but also minimized human exposure to potentially hazardous environments within the manufacturing facility.

TSMC’s commitment to automation has positioned it as a leader in the global semiconductor market. Moreover, companies like Applied Materials have developed specialized robotic solutions tailored for specific applications within semiconductor manufacturing. Their advanced robotic systems are designed for precise material handling during critical processes such as etching and deposition.

By focusing on automation at these critical junctures, Applied Materials has helped clients achieve higher yields and improved product quality.

The Impact of Robotics on the Future of Semiconductor Manufacturing

The integration of robotics into semiconductor manufacturing represents a paradigm shift that is reshaping the industry landscape. As manufacturers strive for greater efficiency, precision, and adaptability in their production processes, robotics will play an increasingly vital role in achieving these goals. The evolution from simple automation to sophisticated robotic systems capable of performing complex tasks reflects a broader trend toward smart manufacturing practices.

Looking ahead, the continued advancement of robotics will likely drive further innovations within semiconductor manufacturing. As AI technologies become more prevalent and sensor capabilities improve, we can expect a new era characterized by highly autonomous production environments where human operators work alongside intelligent machines to achieve unprecedented levels of efficiency and quality. In summary, robotics have not only enhanced current manufacturing practices but have also laid the groundwork for future developments in semiconductor technology.

As this field continues to evolve, it will be essential for manufacturers to embrace these advancements fully while addressing the challenges that accompany them—ultimately leading to a more robust and resilient semiconductor industry capable of meeting the demands of an ever-changing technological landscape.

In a recent article on enicomp.com, the features of the Samsung Galaxy Chromebook 2 are explored in depth. This article delves into how the Chromebook’s innovative design and powerful performance can enhance productivity and creativity for users in various industries, including semiconductor manufacturing. Just like robotics are revolutionizing the manufacturing process, devices like the Samsung Galaxy Chromebook 2 are also playing a crucial role in streamlining workflows and optimizing efficiency in the tech industry.

FAQs

What is the role of robotics in semiconductor manufacturing?

Robotics play a crucial role in semiconductor manufacturing by automating various processes such as wafer handling, packaging, testing, and inspection. This helps in improving efficiency, precision, and overall productivity in the manufacturing process.

How do robotics streamline semiconductor manufacturing?

Robotics streamline semiconductor manufacturing by reducing human intervention, minimizing errors, increasing throughput, and enabling 24/7 operation. They also contribute to the standardization of processes and the implementation of advanced technologies.

What are the benefits of using robotics in semiconductor manufacturing?

The benefits of using robotics in semiconductor manufacturing include improved quality control, increased production capacity, reduced labor costs, enhanced workplace safety, and the ability to handle complex tasks with high precision.

What are some common robotic applications in semiconductor manufacturing?

Common robotic applications in semiconductor manufacturing include material handling, pick-and-place operations, wire bonding, die bonding, wafer inspection, metrology, and packaging. Robotics are also used in cleanroom environments to maintain strict contamination control.

How does robotics contribute to the advancement of semiconductor technology?

Robotics contribute to the advancement of semiconductor technology by enabling the production of smaller and more complex semiconductor components with higher precision and efficiency. They also facilitate the integration of emerging technologies such as artificial intelligence and machine learning in semiconductor manufacturing processes.