The construction industry has long been characterized by its labor-intensive nature, often requiring workers to perform physically demanding and hazardous tasks. As technology continues to evolve, the integration of robotics into construction processes is becoming increasingly prevalent. Robotics in construction encompasses a wide range of automated systems, from robotic arms and drones to autonomous vehicles and 3D printing technologies.

These innovations are not merely enhancements to existing practices; they represent a paradigm shift in how construction projects are planned, executed, and managed. The adoption of robotics in construction is driven by the need for increased efficiency, improved safety, and enhanced precision. As the industry grapples with labor shortages and rising costs, robotics offers a viable solution to streamline operations and mitigate risks associated with dangerous tasks.

By automating repetitive and hazardous activities, construction firms can not only protect their workforce but also improve project timelines and reduce overall costs. This article delves into the various aspects of robotics in construction, focusing on the identification of dangerous tasks, the benefits of automation, real-world examples, challenges faced, safety regulations, and future trends.

Key Takeaways

- Robotics in construction involves the use of automated machines and systems to perform tasks traditionally carried out by human workers.

- Identifying dangerous tasks in construction is crucial for determining where robotics can be implemented to improve safety and efficiency.

- Automating dangerous tasks with robotics can lead to reduced risk of injury, increased productivity, and cost savings for construction companies.

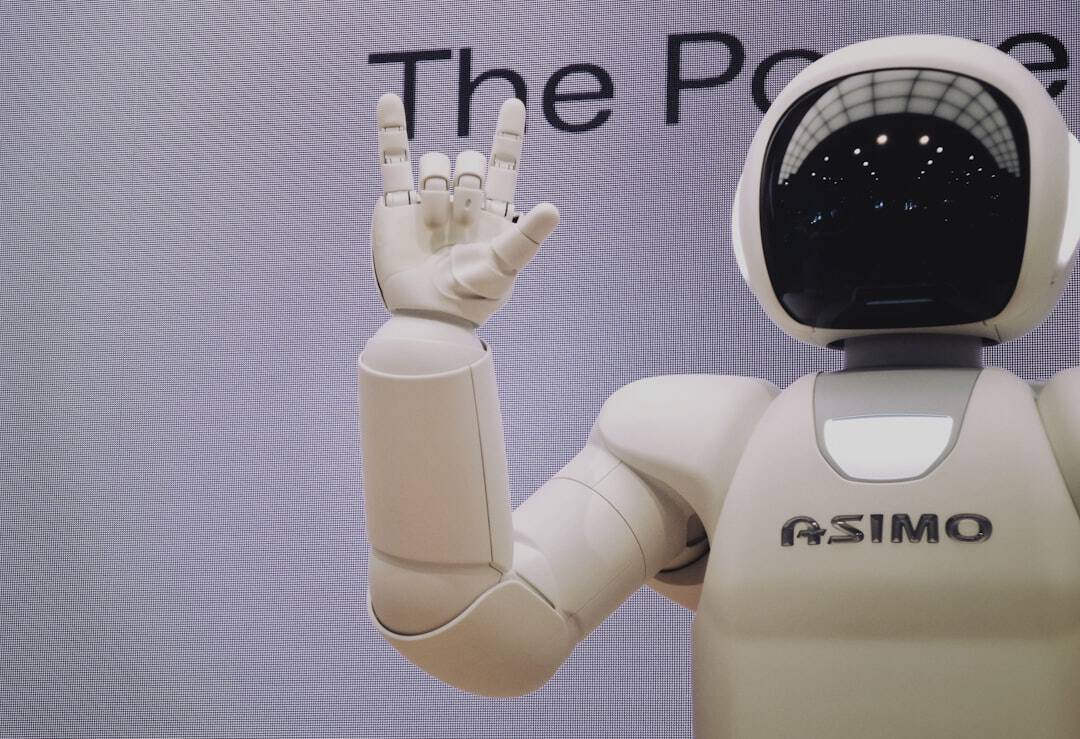

- Examples of robotics in construction include autonomous vehicles, drones, 3D printing, and exoskeletons for heavy lifting.

- Challenges and limitations of robotics in construction include high initial costs, technical limitations, and the need for skilled operators.

Identifying Dangerous Tasks in Construction

Construction sites are fraught with risks, and certain tasks are particularly hazardous due to their inherent nature. Identifying these dangerous tasks is crucial for implementing effective robotic solutions. Common examples include heavy lifting, working at heights, operating machinery, and handling hazardous materials.

For instance, tasks such as hoisting heavy steel beams or pouring concrete can lead to serious injuries if not performed correctly. The physical strain on workers can result in musculoskeletal disorders, while falls from heights remain one of the leading causes of fatalities in the industry. Moreover, tasks that involve exposure to toxic substances or extreme environmental conditions pose significant health risks.

For example, demolition work often requires workers to handle asbestos or lead-based materials, necessitating stringent safety protocols. By pinpointing these high-risk activities, construction companies can prioritize the deployment of robotic systems designed to take over these roles. This not only enhances worker safety but also allows human labor to be redirected toward more skilled tasks that require critical thinking and problem-solving abilities.

The Benefits of Automating Dangerous Tasks with Robotics

The automation of dangerous tasks through robotics offers a multitude of benefits that extend beyond mere safety improvements. One of the most significant advantages is the reduction of workplace injuries and fatalities.

This shift not only protects employees but also fosters a culture of safety within the organization, which can enhance employee morale and retention. In addition to safety benefits, automating dangerous tasks can lead to increased efficiency and productivity. Robots can operate continuously without fatigue, allowing for faster completion of projects.

For example, robotic systems can be programmed to work around the clock, performing repetitive tasks such as bricklaying or welding with precision and speed that surpasses human capabilities. This efficiency translates into cost savings for construction firms, as projects can be completed more quickly and with fewer resources. Furthermore, robotics can enhance the quality of work performed on construction sites.

Automated systems are designed to execute tasks with a high degree of accuracy, reducing the likelihood of errors that can lead to costly rework. For instance, 3D printing technology allows for the creation of complex structures with intricate designs that would be challenging to achieve through traditional methods. By leveraging robotics, construction companies can ensure that their projects meet stringent quality standards while minimizing waste.

Examples of Robotics in Construction

Numerous examples illustrate the successful integration of robotics into construction processes across various applications. One notable instance is the use of drones for site surveying and monitoring. Drones equipped with high-resolution cameras and LiDAR technology can capture detailed aerial imagery of construction sites, enabling project managers to assess progress and identify potential issues from a bird’s-eye view.

This capability not only enhances project oversight but also allows for more informed decision-making throughout the construction process. Another compelling example is the deployment of robotic arms for tasks such as bricklaying and masonry. Companies like Construction Robotics have developed machines like the SAM (Semi-Automated Mason) that can lay bricks at an impressive rate while ensuring consistent quality.

This technology alleviates the physical strain on human workers while maintaining high productivity levels. Additionally, robotic arms are being utilized in prefabrication facilities to assemble components off-site, further streamlining the construction process. Autonomous vehicles are also making waves in the construction sector.

Companies like Built Robotics have developed self-driving bulldozers that can perform earthmoving tasks without human intervention. These vehicles utilize advanced sensors and artificial intelligence to navigate job sites safely while executing tasks such as grading and excavation. The ability to automate these heavy-duty operations not only enhances efficiency but also reduces the risk associated with operating large machinery.

Challenges and Limitations of Robotics in Construction

Despite the promising advancements in robotics for construction, several challenges and limitations must be addressed before widespread adoption can occur. One significant hurdle is the high initial cost associated with implementing robotic systems. The investment required for purchasing advanced machinery, software development, and training personnel can be substantial, particularly for small to medium-sized construction firms.

This financial barrier may deter some companies from exploring robotic solutions despite their long-term benefits. Another challenge lies in the integration of robotics into existing workflows. Construction sites are often dynamic environments characterized by changing conditions and unpredictable variables.

Ensuring that robotic systems can adapt to these fluctuations poses a technical challenge that requires sophisticated programming and real-time data analysis capabilities. Additionally, there may be resistance from workers who fear job displacement due to automation. Addressing these concerns through education and training programs is essential for fostering acceptance of robotics within the workforce.

Moreover, regulatory frameworks governing the use of robotics in construction are still evolving. As technology advances rapidly, existing regulations may lag behind, creating uncertainty for companies looking to implement robotic solutions. Ensuring compliance with safety standards while navigating legal requirements can be a complex process that requires careful planning and consideration.

Safety and Regulations in Implementing Robotics in Construction

The implementation of robotics in construction necessitates a thorough understanding of safety protocols and regulatory requirements. As robots take on more responsibilities on job sites, it is imperative that they operate within established safety guidelines to protect both human workers and equipment. Organizations such as OSHA (Occupational Safety and Health Administration) provide guidelines that outline best practices for integrating automation into construction processes.

Safety measures must be incorporated into the design and operation of robotic systems to minimize risks associated with their use. For instance, robots should be equipped with sensors that detect human presence and halt operations if someone enters their vicinity. Additionally, regular maintenance and inspections are crucial to ensure that robotic systems function correctly and do not pose hazards on site.

As more companies adopt automated solutions, there is a growing need for clear guidelines that govern their use. This includes establishing protocols for training workers on how to interact safely with robotic systems and ensuring that all equipment meets safety certifications.

Future Trends and Innovations in Robotics for Construction

The future of robotics in construction is poised for significant advancements as technology continues to evolve at a rapid pace. One emerging trend is the increased use of artificial intelligence (AI) in robotic systems. AI algorithms can enhance the decision-making capabilities of robots by enabling them to learn from their environment and adapt their actions accordingly.

This could lead to more autonomous systems capable of handling complex tasks without constant human oversight. Another promising innovation is the development of collaborative robots or “cobots” designed to work alongside human workers rather than replace them. These robots can assist with heavy lifting or repetitive tasks while allowing humans to focus on more skilled activities that require creativity and problem-solving abilities.

The integration of cobots into construction workflows has the potential to enhance productivity while maintaining a safe working environment. Additionally, advancements in materials science may lead to new types of construction robots capable of utilizing innovative building materials such as bio-based composites or self-healing concrete. These materials could revolutionize construction practices by improving sustainability and durability while reducing waste.

As 3D printing technology continues to mature, we may also see an increase in large-scale 3D printing applications for constructing entire buildings or components on-site. This approach could drastically reduce labor costs and material waste while allowing for greater design flexibility.

The Impact of Robotics in Automating Dangerous Tasks in Construction

The integration of robotics into construction represents a transformative shift that has far-reaching implications for safety, efficiency, and quality within the industry. By automating dangerous tasks traditionally performed by human workers, companies can significantly reduce workplace injuries while enhancing productivity levels across projects. The examples of drones, robotic arms, and autonomous vehicles illustrate how technology is already reshaping construction practices.

However, challenges remain regarding costs, integration into existing workflows, regulatory compliance, and workforce acceptance. Addressing these issues will be crucial for maximizing the benefits of robotics in construction while ensuring a safe working environment for all employees. As we look toward the future, ongoing innovations in AI, collaborative robots, advanced materials, and 3D printing will likely drive further advancements in this field.

The potential for robotics to revolutionize construction practices is immense, paving the way for safer job sites and more efficient project delivery methods that will ultimately benefit both workers and clients alike.

In a related article discussing the advancements in technology, particularly in the field of education, the Best Laptop for Teachers in 2023 highlights the importance of equipping educators with the right tools to enhance their teaching methods. Just as robotics are revolutionizing the construction industry by automating dangerous tasks, laptops are transforming the way teachers engage with students and deliver lessons. Both articles underscore the significant impact of technology in streamlining processes and improving efficiency in various sectors.

FAQs

What is the role of robotics in automating dangerous tasks in construction?

Robotics plays a crucial role in automating dangerous tasks in construction by taking over tasks that pose a risk to human workers, such as heavy lifting, working at heights, and working in hazardous environments.

How do robotics improve safety in construction?

Robotics improve safety in construction by reducing the exposure of human workers to dangerous tasks, minimizing the risk of accidents and injuries, and enhancing overall safety protocols on construction sites.

What are some examples of dangerous tasks in construction that can be automated with robotics?

Examples of dangerous tasks in construction that can be automated with robotics include demolition, excavation, welding, and working in confined spaces or extreme temperatures.

What are the benefits of using robotics to automate dangerous tasks in construction?

The benefits of using robotics to automate dangerous tasks in construction include improved safety for human workers, increased efficiency and productivity, and the ability to complete tasks in challenging environments.

What are the challenges of implementing robotics in construction for automating dangerous tasks?

Challenges of implementing robotics in construction for automating dangerous tasks include the initial investment cost, the need for specialized training for operating and maintaining robotic systems, and the integration of robotics with existing construction processes.