The automotive industry has undergone a remarkable transformation over the past few decades, driven largely by advancements in automation technology. This evolution has not only enhanced production efficiency but has also redefined the way vehicles are designed, manufactured, and delivered to consumers. Automation encompasses a wide range of technologies, including robotics, artificial intelligence (AI), and the Internet of Things (IoT), all of which play a pivotal role in streamlining operations and improving overall productivity.

As the industry continues to embrace these innovations, it is essential to understand how automation is reshaping various facets of automotive production and service. The integration of automation into the automotive sector is not merely a trend; it represents a fundamental shift in how companies operate. With increasing global competition and rising consumer expectations, manufacturers are compelled to adopt automated solutions to remain relevant.

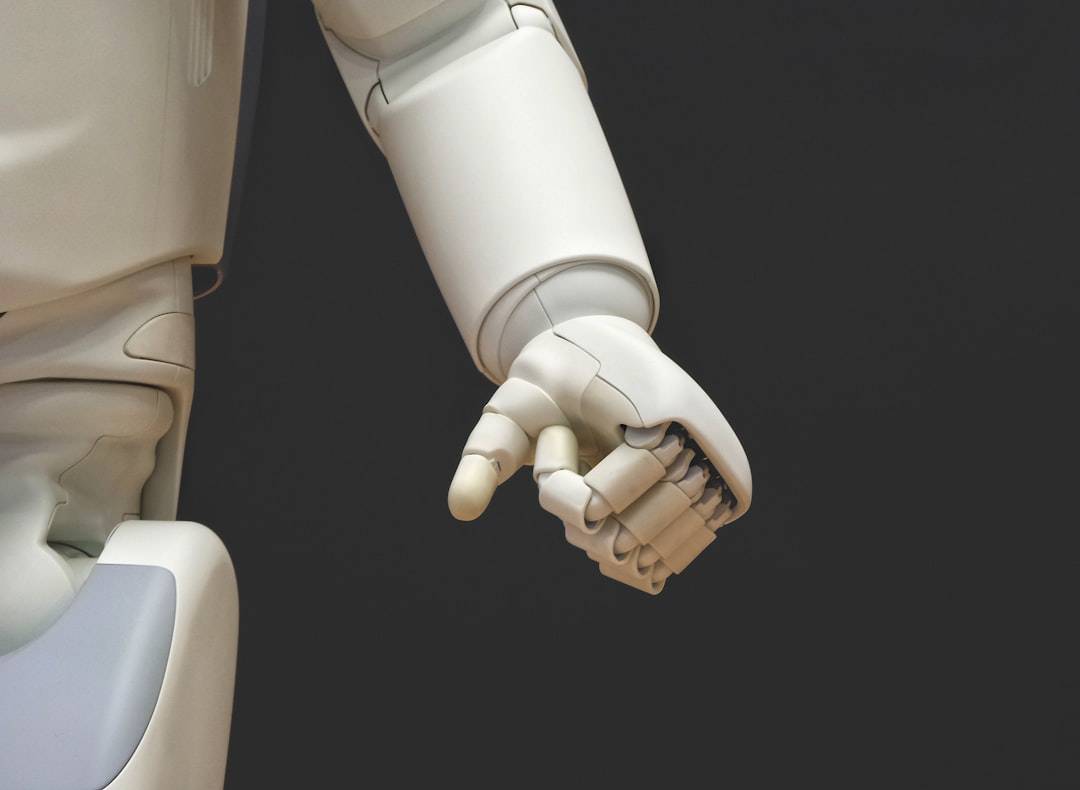

From assembly lines that utilize robotic arms for precision tasks to sophisticated software systems that manage supply chains, automation is at the heart of modern automotive production. This article delves into the multifaceted applications of automation within the automotive industry, exploring its impact on manufacturing processes, supply chain management, quality control, inventory management, maintenance, and customer service.

Key Takeaways

- Automation in the automotive industry has revolutionized manufacturing processes, supply chain management, quality control, inventory management, maintenance and repairs, and customer service.

- In manufacturing processes, automation has led to increased efficiency, precision, and cost savings through the use of robotics and advanced technologies.

- Automation in supply chain management has improved inventory tracking, demand forecasting, and logistics, leading to streamlined operations and reduced lead times.

- Quality control has been enhanced through automation with the use of sensors, cameras, and data analytics to detect defects and ensure consistent product quality.

- Automation in inventory management has enabled real-time monitoring, optimization of stock levels, and improved accuracy in order fulfillment, leading to reduced carrying costs and improved customer satisfaction.

Automation in Manufacturing Processes

Increased Efficiency and Accuracy

Robotic systems have become an integral part of assembly lines, performing tasks such as welding, painting, and assembling intricate components with unparalleled speed and accuracy. Companies like Tesla have successfully implemented advanced robotics in their production facilities, enabling rapid scaling of vehicle output while maintaining high standards of quality.

Reduced Errors and Improved Flexibility

These robots can work tirelessly, reducing the need for human intervention in repetitive tasks and minimizing the risk of errors that can occur due to fatigue. Moreover, automation has facilitated the adoption of flexible manufacturing systems (FMS), which enable manufacturers to produce a variety of vehicle models on the same assembly line. This adaptability is crucial in today’s market, where consumer preferences can shift rapidly.

Enhanced Customization and Optimized Production

By utilizing automated machinery that can be reprogrammed for different tasks, manufacturers can respond more swiftly to changes in demand without incurring significant downtime or costs. The implementation of automation in manufacturing not only enhances efficiency but also allows for greater customization of vehicles, catering to individual consumer preferences while optimizing production schedules.

Automation in Supply Chain Management

The complexity of supply chain management in the automotive industry necessitates the use of automation to ensure seamless operations. With numerous suppliers and logistics partners involved in the production process, managing these relationships effectively is critical. Automated systems can track inventory levels, monitor supplier performance, and predict demand fluctuations with remarkable accuracy.

For example, companies like Ford have adopted advanced analytics and machine learning algorithms to optimize their supply chain operations, enabling them to anticipate potential disruptions and adjust their strategies accordingly. Furthermore, automation facilitates real-time data sharing across the supply chain, enhancing collaboration among stakeholders. By utilizing cloud-based platforms and IoT devices, manufacturers can gain visibility into every aspect of their supply chain, from raw material procurement to final delivery.

This transparency allows for quicker decision-making and more efficient resource allocation. Automated supply chain management systems can also reduce lead times and minimize excess inventory, ultimately lowering costs and improving profitability for automotive manufacturers.

Automation in Quality Control

Quality control is a critical aspect of automotive manufacturing, as even minor defects can lead to significant safety issues and costly recalls. Automation has transformed quality assurance processes by introducing advanced inspection technologies that ensure products meet stringent standards. Automated vision systems equipped with high-resolution cameras and AI algorithms can detect defects in real-time during production.

For instance, BMW employs automated inspection systems that analyze components for imperfections at various stages of assembly, ensuring that only flawless parts proceed to the next phase. In addition to visual inspections, automation enables comprehensive data collection and analysis throughout the manufacturing process. By leveraging big data analytics, manufacturers can identify patterns and trends related to quality issues, allowing them to implement corrective actions proactively.

This data-driven approach not only enhances product quality but also fosters a culture of continuous improvement within organizations. As a result, automotive companies can maintain their reputations for reliability and safety while minimizing waste and rework associated with defective products.

Automation in Inventory Management

Effective inventory management is essential for automotive manufacturers to maintain operational efficiency and meet customer demands. Automation plays a vital role in optimizing inventory levels by providing real-time visibility into stock availability and usage patterns. Automated inventory management systems utilize barcodes or RFID technology to track parts and materials throughout the production process.

This level of tracking ensures that manufacturers can quickly identify shortages or surpluses and adjust their procurement strategies accordingly. Moreover, automated systems can forecast inventory needs based on historical data and market trends. By analyzing sales patterns and production schedules, these systems can predict when certain components will be required, allowing manufacturers to order materials just-in-time rather than maintaining excessive stock levels.

This approach not only reduces carrying costs but also minimizes the risk of obsolescence for parts that may become outdated due to rapid technological advancements in the automotive sector.

Automation in Maintenance and Repairs

The maintenance and repair segment of the automotive industry has also benefited significantly from automation technologies. Predictive maintenance solutions powered by IoT sensors enable manufacturers and service providers to monitor vehicle performance continuously. These sensors collect data on various parameters such as engine temperature, oil pressure, and brake wear, allowing for real-time analysis of a vehicle’s condition.

For example, General Motors has implemented predictive maintenance systems that alert drivers when their vehicles require servicing based on actual usage patterns rather than arbitrary schedules. Additionally, automation has streamlined repair processes through the use of augmented reality (AR) and virtual reality (VR) technologies. Technicians can utilize AR glasses that overlay digital information onto physical components during repairs, guiding them through complex procedures with step-by-step instructions.

This not only enhances efficiency but also reduces the likelihood of errors during repairs. As vehicles become increasingly sophisticated with advanced electronics and software systems, automated maintenance solutions will be crucial in ensuring that they remain safe and operational throughout their lifecycle.

Automation in Customer Service

In an era where customer experience is paramount, automation has emerged as a powerful tool for enhancing service delivery in the automotive industry. Chatbots powered by AI are now commonplace on manufacturer websites and customer service platforms, providing instant responses to inquiries about vehicle features, pricing, and availability. These virtual assistants can handle a multitude of queries simultaneously, significantly reducing wait times for customers seeking information or assistance.

Moreover, automation extends beyond initial inquiries; it also plays a role in post-purchase support. Automated follow-up systems can send personalized messages to customers after a vehicle purchase or service appointment, soliciting feedback or offering additional services based on their preferences. This proactive approach not only fosters customer loyalty but also provides valuable insights into consumer behavior that can inform future marketing strategies.

As automotive companies continue to leverage automation in customer service, they will be better positioned to meet evolving consumer expectations and enhance overall satisfaction.

The Future of Automation in the Automotive Industry

The future of automation in the automotive industry is poised for further evolution as technology continues to advance at an unprecedented pace. Emerging trends such as autonomous vehicles and smart manufacturing will likely redefine traditional paradigms within the sector. As manufacturers increasingly adopt AI-driven solutions for design and production processes, we can expect even greater efficiencies and innovations that will shape the next generation of vehicles.

Moreover, as sustainability becomes a focal point for consumers and regulators alike, automation will play a crucial role in optimizing resource usage and reducing waste throughout the automotive lifecycle. From energy-efficient manufacturing processes to eco-friendly supply chain practices, automated solutions will be integral in helping companies meet their sustainability goals while remaining competitive in a rapidly changing market landscape. In summary, automation is not just enhancing existing processes within the automotive industry; it is fundamentally transforming how vehicles are conceived, produced, maintained, and serviced.

As we look ahead, it is clear that embracing automation will be essential for automotive manufacturers seeking to thrive in an increasingly complex and dynamic environment.

A related article discussing the advancements in technology can be found in the article “The Best Lenovo Laptops.” This article highlights the innovative features and capabilities of Lenovo laptops, showcasing how technology is constantly evolving and improving. Just like automation is revolutionizing the automotive industry, Lenovo laptops are pushing the boundaries of what is possible in the world of computing. Both industries are benefiting from advancements in technology that are helping to reduce costs and increase efficiency.

FAQs

What is automation in the automotive industry?

Automation in the automotive industry refers to the use of advanced technology and robotics to perform tasks that were previously carried out by human workers. This can include tasks such as assembly, painting, welding, and quality control.

How does automation reduce costs in the automotive industry?

Automation reduces costs in the automotive industry by increasing efficiency, improving quality control, and reducing the need for manual labor. This can lead to lower production costs, decreased waste, and improved overall productivity.

What are some examples of automation in the automotive industry?

Examples of automation in the automotive industry include the use of robotic arms for assembly, automated guided vehicles for material handling, and automated inspection systems for quality control.

What are the benefits of automation in the automotive industry?

The benefits of automation in the automotive industry include increased productivity, improved product quality, reduced labor costs, and enhanced workplace safety. Automation also allows for greater flexibility in production processes.

Are there any challenges associated with implementing automation in the automotive industry?

Some challenges associated with implementing automation in the automotive industry include the high initial investment costs, the need for specialized technical expertise, and potential job displacement for manual laborers. Additionally, integrating automation into existing production processes can be complex and time-consuming.