In recent years, the landscape of supply chain management has undergone a profound transformation, largely driven by the advent of automation technologies. As businesses strive to enhance their operational efficiency and responsiveness to market demands, automation has emerged as a pivotal strategy. This shift is not merely a trend; it represents a fundamental change in how goods and services are produced, distributed, and delivered.

Automation encompasses a wide array of technologies, including robotics, artificial intelligence (AI), machine learning, and the Internet of Things (IoT), all of which work in concert to streamline processes, reduce human error, and optimize resource allocation. The integration of these technologies into supply chain operations is reshaping traditional practices, enabling organizations to respond more swiftly to fluctuations in demand while maintaining high levels of quality and service. The impetus for this shift towards automation is multifaceted.

On one hand, the increasing complexity of global supply chains necessitates more sophisticated solutions to manage logistics, inventory, and customer expectations. On the other hand, the competitive landscape compels companies to seek out innovative ways to reduce costs and improve efficiency. As consumer preferences evolve and the demand for faster delivery times intensifies, businesses are recognizing that automation is not just an option but a necessity for survival.

By leveraging automated systems, organizations can achieve greater visibility across their supply chains, enhance decision-making capabilities, and ultimately deliver superior value to their customers. This article will delve into the myriad benefits of automation in supply chain efficiency, explore the technologies driving this change, examine successful case studies, address the challenges and risks associated with automation, and consider future trends that will shape the industry.

Key Takeaways

- Automation in supply chain management involves the use of technology to streamline and optimize processes, reducing manual intervention and increasing efficiency.

- The benefits of automation in supply chain management include improved accuracy, reduced lead times, lower operational costs, and enhanced customer satisfaction.

- Automation technologies in supply chain management include robotics, artificial intelligence, machine learning, Internet of Things (IoT), and advanced analytics.

- Case studies of successful automation implementation in supply chain management demonstrate significant improvements in inventory management, order fulfillment, and overall operational efficiency.

- Challenges and risks of automation in supply chain management include initial investment costs, integration complexities, cybersecurity threats, and potential job displacement.

- Future trends and innovations in automation for supply chain efficiency include the adoption of autonomous vehicles, blockchain technology for transparent and secure transactions, and the use of predictive analytics for demand forecasting.

- In conclusion, the impact of automation on supply chain efficiency is undeniable, with the potential to revolutionize the way businesses manage their operations and deliver value to customers.

Benefits of Automation in Supply Chain Efficiency

Enhancing Operational Efficiency

The benefits of automation in supply chain management are extensive and multifaceted, fundamentally altering how organizations operate. One of the most significant advantages is the enhancement of operational efficiency. Automated systems can perform repetitive tasks with remarkable speed and accuracy, reducing the time required for processes such as order fulfillment, inventory management, and shipping logistics.

Minimizing Errors and Fostering Innovation

This increased efficiency not only accelerates the overall supply chain cycle but also minimizes the likelihood of human error, which can lead to costly mistakes and delays. By automating routine tasks, companies can reallocate their human resources to more strategic roles that require critical thinking and creativity, thereby fostering a more innovative workplace culture. Moreover, automation contributes to improved data accuracy and real-time visibility within the supply chain.

Data-Driven Decision Making

With advanced technologies such as AI and IoT, organizations can collect and analyze vast amounts of data from various sources, providing insights that were previously unattainable. This data-driven approach enables businesses to make informed decisions based on real-time information about inventory levels, demand forecasts, and supplier performance. As a result, companies can optimize their inventory management practices, reducing excess stock while ensuring that they meet customer demands promptly.

Strengthening Competitive Position

The ability to respond quickly to market changes not only enhances customer satisfaction but also strengthens a company’s competitive position in an increasingly dynamic marketplace.

Automation Technologies in Supply Chain Management

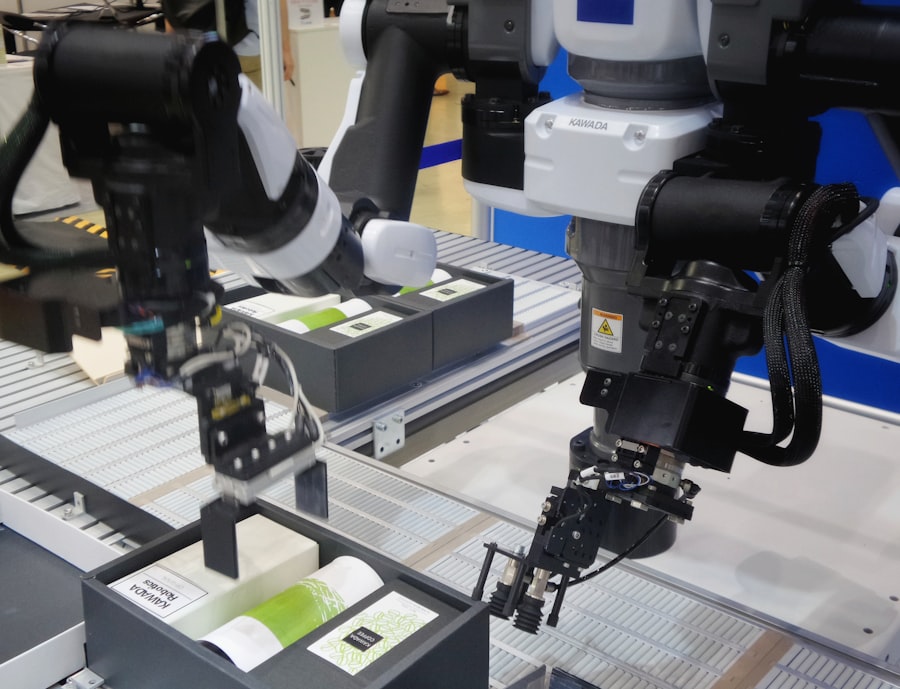

The landscape of automation technologies in supply chain management is diverse and continually evolving. Robotics is one of the most prominent technologies making waves in this sector. Automated guided vehicles (AGVs) and robotic arms are increasingly being deployed in warehouses and distribution centers to handle tasks such as picking, packing, and sorting.

These machines can operate around the clock without fatigue, significantly increasing throughput while reducing labor costs. Furthermore, advancements in machine learning algorithms enable these robots to adapt to changing environments and improve their performance over time, making them invaluable assets in modern supply chains. In addition to robotics, artificial intelligence plays a crucial role in enhancing supply chain operations.

AI-driven analytics tools can process vast datasets to identify patterns and trends that inform strategic decision-making. For instance, predictive analytics can forecast demand fluctuations based on historical data and market trends, allowing companies to adjust their production schedules accordingly. Additionally, AI can optimize routing for transportation logistics by analyzing traffic patterns and delivery windows, ensuring that goods reach their destinations as efficiently as possible.

The integration of these technologies not only streamlines operations but also empowers organizations to be more agile and responsive in an ever-changing business environment.

Case Studies of Successful Automation Implementation in Supply Chain

Numerous organizations have successfully implemented automation technologies within their supply chains, yielding impressive results that serve as benchmarks for others in the industry. One notable example is Amazon, which has revolutionized e-commerce logistics through its extensive use of automation. The company employs a sophisticated network of robots in its fulfillment centers that work alongside human employees to pick and pack orders efficiently.

This integration has allowed Amazon to significantly reduce order processing times while maintaining high accuracy levels. Furthermore, Amazon’s use of machine learning algorithms for demand forecasting has enabled it to optimize inventory levels across its vast network of warehouses, ensuring that products are readily available for customers when they need them. Another compelling case study is that of Unilever, a global consumer goods company that has embraced automation to enhance its supply chain sustainability efforts.

Unilever implemented an automated inventory management system that leverages IoT sensors to monitor stock levels in real-time across its distribution centers. This technology has not only improved inventory accuracy but also reduced waste by ensuring that products are delivered just-in-time rather than being overproduced or left unsold on shelves. Additionally, Unilever’s use of AI-driven analytics has allowed it to optimize its transportation routes, resulting in lower carbon emissions and reduced transportation costs.

These examples illustrate how automation can drive efficiency while also aligning with broader sustainability goals.

Challenges and Risks of Automation in Supply Chain Management

Despite the numerous advantages associated with automation in supply chain management, organizations must also navigate a range of challenges and risks that accompany this transition. One significant concern is the potential for job displacement as automated systems take over tasks traditionally performed by human workers. While automation can lead to increased efficiency and cost savings, it may also result in workforce reductions or shifts in job roles that require employees to adapt to new technologies.

Companies must approach this challenge with sensitivity and foresight by investing in employee training programs that equip workers with the skills needed to thrive in an automated environment. Another challenge lies in the initial investment required for implementing automation technologies. The costs associated with acquiring advanced machinery, software systems, and infrastructure upgrades can be substantial, particularly for small to medium-sized enterprises (SMEs).

Additionally, organizations must consider ongoing maintenance costs and potential disruptions during the transition period as they integrate new systems into their existing operations. To mitigate these risks, businesses should conduct thorough cost-benefit analyses before embarking on automation initiatives and develop comprehensive implementation plans that account for potential obstacles along the way.

Future Trends and Innovations in Automation for Supply Chain Efficiency

Emerging Trends in Supply Chain Automation

Looking ahead, several trends and innovations are poised to shape the future of automation in supply chain management. One notable trend is the increasing adoption of blockchain technology to enhance transparency and traceability within supply chains. By creating immutable records of transactions that can be accessed by all stakeholders involved in the supply chain process, blockchain can help mitigate fraud and ensure compliance with regulatory standards.

Enhancing Transparency and Trust

This level of transparency not only builds trust among consumers but also enables companies to respond more effectively to disruptions by providing real-time visibility into their supply chains. With blockchain technology, organizations can ensure that their supply chains are transparent, secure, and compliant with regulatory requirements.

Advancements in Artificial Intelligence and Augmented Reality

Additionally, advancements in artificial intelligence are expected to drive further innovations in supply chain automation. As AI algorithms become more sophisticated, they will enable organizations to automate complex decision-making processes that were previously reliant on human judgment. For instance, AI could facilitate dynamic pricing strategies based on real-time market conditions or optimize production schedules by analyzing multiple variables simultaneously. Furthermore, the integration of augmented reality (AR) into warehouse operations could enhance training programs for employees while improving picking accuracy through visual guidance systems.

The Impact of Automation on Supply Chain Efficiency

In conclusion, the impact of automation on supply chain efficiency is profound and far-reaching. As organizations continue to embrace advanced technologies such as robotics, artificial intelligence, and IoT, they are unlocking new levels of operational efficiency that were once thought unattainable. The benefits of automation extend beyond mere cost savings; they encompass enhanced data accuracy, improved decision-making capabilities, and greater responsiveness to market demands.

However, it is essential for businesses to approach this transition thoughtfully by addressing potential challenges such as workforce displacement and initial investment costs. As we look toward the future, it is clear that automation will play an increasingly central role in shaping supply chain management practices across industries. The ongoing evolution of technology will continue to drive innovations that enhance transparency, optimize processes, and foster sustainability within supply chains.

Ultimately, organizations that successfully navigate this landscape will not only improve their operational efficiency but also position themselves as leaders in an ever-changing global marketplace. The journey toward automation may be fraught with challenges; however, the rewards it offers make it an indispensable component of modern supply chain strategy.

In exploring the impact of automation on supply chain efficiency, it’s also beneficial to consider how technological advancements influence various aspects of business operations. A related article that delves into the use of advanced tools for optimizing content in digital marketing is Boost Your Content with NeuronWriter: SEO & NLP Optimization. This article discusses how NeuronWriter, incorporating SEO and NLP techniques, can enhance online visibility and engagement, which is crucial for businesses looking to streamline their marketing strategies alongside their supply chains. Understanding these tools can provide insights into the broader scope of automation across business functions.

FAQs

What is automation in the context of supply chain management?

Automation in supply chain management refers to the use of technology and software to streamline and optimize various processes such as inventory management, order fulfillment, and transportation logistics. This can include the use of robotics, artificial intelligence, and machine learning to automate repetitive tasks and improve overall efficiency.

How does automation enhance supply chain efficiency?

Automation enhances supply chain efficiency by reducing human error, increasing speed and accuracy of processes, and enabling real-time tracking and monitoring of inventory and shipments. It also allows for better forecasting and demand planning, leading to improved inventory management and reduced lead times.

What are some examples of automation in supply chain management?

Examples of automation in supply chain management include automated warehouse systems, robotic process automation for order processing, automated inventory replenishment systems, and transportation management systems that optimize route planning and carrier selection.

What are the benefits of implementing automation in the supply chain?

The benefits of implementing automation in the supply chain include cost savings through reduced labor and operational expenses, improved accuracy and reliability of processes, faster order fulfillment and delivery times, better visibility and control over inventory, and the ability to adapt to changing market demands more effectively.

What are the potential challenges of implementing automation in the supply chain?

Challenges of implementing automation in the supply chain can include the initial investment costs, integration with existing systems and processes, potential job displacement for workers, and the need for ongoing maintenance and updates to the technology. Additionally, there may be resistance to change from employees and stakeholders.