Advanced motion control refers to the sophisticated techniques and technologies employed to manage the movement of machinery and equipment with precision and efficiency. This field encompasses a variety of methods, including servo control, stepper motors, and various feedback systems that ensure accurate positioning and speed regulation. The evolution of motion control has been driven by the increasing demand for automation in industrial settings, where the need for high performance, reliability, and flexibility is paramount.

As industries strive to enhance productivity and reduce operational costs, advanced motion control systems have emerged as critical components in achieving these goals. The integration of advanced motion control systems into industrial automation has transformed traditional manufacturing processes. By leveraging cutting-edge technologies such as digital signal processing, artificial intelligence, and machine learning, these systems can adapt to changing conditions in real-time, optimizing performance and minimizing downtime.

The ability to control motion with high precision not only improves the quality of products but also enables manufacturers to respond swiftly to market demands. As a result, advanced motion control is not merely a technical enhancement; it represents a fundamental shift in how industries operate and compete in an increasingly complex global landscape.

Key Takeaways

- Advanced motion control plays a crucial role in industrial automation by enabling precise and efficient movement of machinery and equipment.

- Various types of advanced motion control technologies, such as servo motors, stepper motors, and hydraulic systems, are used in industrial automation to achieve different levels of precision and control.

- Advanced motion control finds applications in various industries, including automotive, aerospace, robotics, and packaging, to improve productivity, quality, and safety.

- The benefits of using advanced motion control in industrial automation include increased accuracy, higher speed, reduced downtime, and improved energy efficiency.

- Despite its advantages, advanced motion control also presents challenges and limitations, such as high initial costs, complex integration, and the need for skilled personnel.

The Importance of Advanced Motion Control in Industrial Automation

Enhancing Product Quality and Reducing Errors

Advanced motion control systems facilitate the automation of complex tasks that would be difficult or impossible to achieve manually.

Increasing Flexibility in Manufacturing Processes

Moreover, advanced motion control systems contribute to the flexibility of manufacturing processes. In industries such as automotive or electronics, where product designs frequently change, the ability to quickly reprogram machines for different tasks is invaluable. This adaptability allows manufacturers to switch between production runs with minimal downtime, thereby maximizing resource utilization.

Implementing Efficient Manufacturing Strategies

The integration of advanced motion control technologies enables companies to implement just-in-time manufacturing strategies, which further enhances efficiency by aligning production closely with demand.

Types of Advanced Motion Control Technologies

A variety of advanced motion control technologies are employed across different industrial applications, each offering unique advantages tailored to specific needs. Servo motors are among the most widely used technologies in this domain. These motors utilize feedback mechanisms to provide precise control over position, speed, and torque.

Servo systems are particularly effective in applications requiring high accuracy and rapid response times, such as robotics and CNC machining. The closed-loop nature of servo systems allows for real-time adjustments based on feedback from sensors, ensuring optimal performance even in dynamic environments. Another significant technology is stepper motors, which operate by dividing a full rotation into a series of discrete steps.

This characteristic makes them ideal for applications where precise positioning is required without the need for complex feedback systems. Stepper motors are commonly used in 3D printers and automated assembly equipment due to their simplicity and cost-effectiveness. Additionally, linear motors represent a cutting-edge advancement in motion control technology.

Unlike traditional rotary motors, linear motors provide direct linear motion without the need for mechanical conversion, resulting in faster speeds and reduced wear on components.

Applications of Advanced Motion Control in Industrial Automation

Advanced motion control technologies find applications across a wide range of industries, each benefiting from enhanced precision and efficiency. In the manufacturing sector, robotics plays a pivotal role in automating repetitive tasks such as welding, painting, and assembly. Robotic arms equipped with advanced motion control systems can perform intricate movements with high accuracy, significantly improving production rates while reducing labor costs.

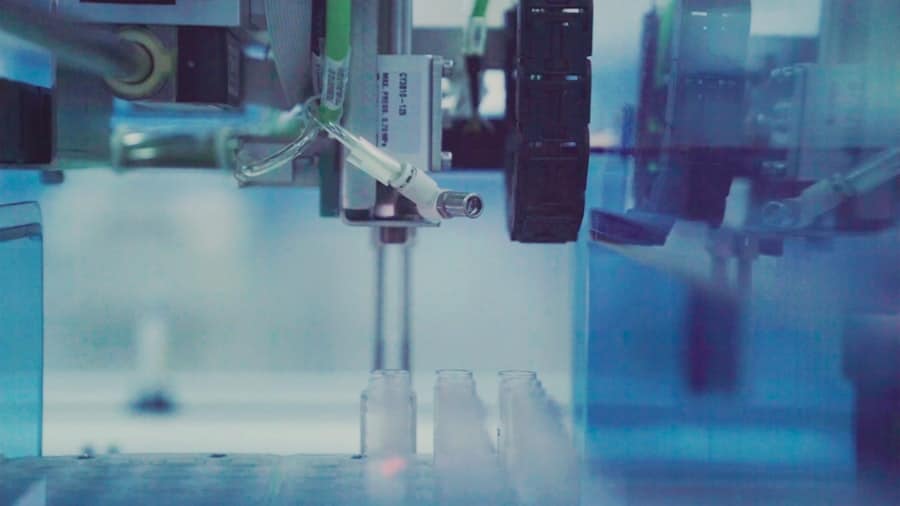

For example, automotive manufacturers utilize robotic welding systems that rely on precise motion control to ensure consistent weld quality across thousands of vehicles. In the packaging industry, advanced motion control is essential for high-speed operations that require synchronization between multiple machines. Automated packaging lines often incorporate vision systems that detect product orientation and position, allowing motion control systems to adjust accordingly.

This capability ensures that products are packaged efficiently without delays or errors. Furthermore, industries such as pharmaceuticals and food processing rely on advanced motion control for filling and capping processes, where maintaining hygiene and accuracy is critical.

Benefits of Using Advanced Motion Control in Industrial Automation

The adoption of advanced motion control systems offers numerous benefits that extend beyond mere operational efficiency. One of the primary advantages is improved product quality. By ensuring precise movements and accurate positioning, manufacturers can minimize defects and variations in their products.

This consistency not only enhances customer satisfaction but also reduces waste associated with rework or scrap materials. Another significant benefit is increased productivity. Advanced motion control systems enable machines to operate at higher speeds while maintaining accuracy, leading to shorter cycle times and greater output.

For instance, in a high-volume production environment, the ability to rapidly switch between different product configurations without extensive downtime can lead to substantial gains in overall throughput. Additionally, these systems often incorporate predictive maintenance capabilities that monitor performance metrics in real-time, allowing for proactive interventions before failures occur. This predictive approach reduces unplanned downtime and extends the lifespan of equipment.

Challenges and Limitations of Advanced Motion Control

Despite the numerous advantages offered by advanced motion control technologies, several challenges and limitations persist within the field. One significant challenge is the complexity associated with integrating these systems into existing manufacturing processes. Many facilities operate with legacy equipment that may not be compatible with modern motion control solutions.

Upgrading or retrofitting older machines can be costly and time-consuming, often requiring specialized expertise to ensure seamless integration. Another limitation lies in the initial investment required for advanced motion control systems. While the long-term benefits often outweigh these costs, smaller manufacturers may struggle to justify the expenditure upfront.

Additionally, the rapid pace of technological advancement can lead to concerns about obsolescence; companies may hesitate to invest in new systems if they fear that newer technologies will emerge shortly after their purchase. Furthermore, as automation increases, there is a growing need for skilled personnel who can operate and maintain these sophisticated systems, creating a potential skills gap in the workforce.

Future Trends in Advanced Motion Control for Industrial Automation

The future of advanced motion control in industrial automation is poised for significant evolution driven by emerging technologies and changing market demands. One notable trend is the increasing integration of artificial intelligence (AI) and machine learning into motion control systems. These technologies enable systems to learn from historical data and adapt their operations based on real-time conditions.

For example, AI algorithms can optimize motion profiles for specific tasks by analyzing performance data from previous runs, leading to enhanced efficiency and reduced energy consumption. Another trend is the growing emphasis on collaborative robotics (cobots), which are designed to work alongside human operators safely. Advanced motion control plays a crucial role in ensuring that cobots can perform tasks with precision while responding appropriately to human presence.

This collaboration enhances productivity while maintaining safety standards in environments where humans and machines interact closely.

This connectivity will facilitate real-time monitoring and control over vast networks of machines, allowing for more sophisticated automation strategies that can respond dynamically to changes in production conditions.

The Impact of Advanced Motion Control on Industrial Automation

The impact of advanced motion control on industrial automation is profound and multifaceted. As industries continue to embrace automation as a means of enhancing productivity and competitiveness, advanced motion control technologies will play an increasingly central role in shaping manufacturing processes. From improving product quality through precise movements to enabling flexible production capabilities that respond swiftly to market demands, these systems are integral to modern industrial operations.

As we look ahead, the ongoing advancements in technology promise to further enhance the capabilities of motion control systems. The integration of AI, machine learning, and improved communication networks will enable even greater levels of automation and efficiency. While challenges remain regarding integration costs and workforce skills, the potential benefits far outweigh these obstacles.

Ultimately, advanced motion control will continue to drive innovation within industrial automation, paving the way for smarter factories that leverage technology to achieve unprecedented levels of performance and productivity.

In a related article, How One Founder Realized the Potential of Sustainable Energy, the focus is on the innovative ways in which entrepreneurs are harnessing sustainable energy sources to drive industrial automation. This article highlights the importance of incorporating advanced motion control technologies in industrial processes to optimize efficiency and reduce environmental impact. By leveraging sustainable energy solutions, companies can not only improve their bottom line but also contribute to a more eco-friendly future.

FAQs

What is advanced motion control in industrial automation?

Advanced motion control in industrial automation refers to the use of sophisticated control systems to precisely regulate the movement of machinery and equipment in manufacturing and industrial processes. This technology allows for greater accuracy, speed, and efficiency in the operation of automated systems.

What are the key components of advanced motion control systems?

Key components of advanced motion control systems include servo motors, drives, controllers, and feedback devices such as encoders and sensors. These components work together to accurately control the speed, position, and torque of machinery in industrial automation applications.

What are the benefits of advanced motion control in industrial automation?

The benefits of advanced motion control in industrial automation include improved precision, increased productivity, reduced downtime, energy efficiency, and the ability to perform complex tasks with greater accuracy. These systems also enable seamless integration with other automation technologies.

How is advanced motion control used in industrial automation applications?

Advanced motion control is used in a wide range of industrial automation applications, including robotics, CNC machining, packaging, material handling, and assembly lines. It is also utilized in industries such as automotive, aerospace, electronics, and pharmaceuticals to optimize manufacturing processes.

What are some examples of advanced motion control technologies?

Examples of advanced motion control technologies include multi-axis motion controllers, high-performance servo drives, precision linear actuators, and advanced motion planning and trajectory optimization software. These technologies enable precise control of motion in industrial automation systems.