Soft robotics is an emerging field that diverges from traditional rigid robotic systems by utilizing flexible materials and structures. This innovative approach allows robots to interact with their environment in a more adaptable and gentle manner, making them particularly suitable for tasks that require delicate handling. The concept of soft robotics draws inspiration from biological organisms, which often exhibit soft, flexible bodies that enable them to navigate complex environments and manipulate objects with precision.

By mimicking these natural systems, researchers and engineers are developing robots that can perform tasks previously deemed too challenging or risky for conventional machines. The significance of soft robotics extends beyond mere academic curiosity; it has profound implications for various industries, particularly in material handling. As supply chains become increasingly complex and the demand for automation rises, the need for versatile and efficient robotic solutions has never been greater.

Soft robots can navigate tight spaces, handle fragile items, and adapt to varying shapes and sizes, making them ideal candidates for modern material handling applications. This adaptability not only enhances operational efficiency but also reduces the risk of damage to goods, ultimately leading to cost savings and improved service delivery.

Key Takeaways

- Soft robotics is a rapidly growing field that focuses on the development of robots using soft and flexible materials.

- Current challenges in material handling include the limitations of traditional rigid robots in handling delicate and irregularly shaped objects.

- Soft robotics offers advantages such as improved dexterity, adaptability to complex environments, and enhanced safety for human-robot interaction in material handling tasks.

- Recent developments in soft robotics technology include the use of advanced materials, bio-inspired designs, and innovative control systems for improved performance.

- Applications of soft robotics in material handling range from warehouse automation and logistics to food processing and healthcare, with potential for further expansion in the future.

Current Challenges in Material Handling

Material handling encompasses a wide range of activities, including the movement, protection, storage, and control of materials throughout the manufacturing and distribution processes. Despite advancements in automation, the industry faces several challenges that hinder efficiency and productivity. One of the primary issues is the handling of diverse materials with varying shapes, sizes, and fragility.

Traditional robotic systems often struggle with these variations, leading to increased downtime and the need for manual intervention. This limitation can result in bottlenecks in production lines and delays in order fulfillment. Another significant challenge is the safety of both workers and products during the handling process.

Rigid robots, while powerful, can pose risks due to their strength and speed. Accidental collisions can lead to injuries or damage to goods, necessitating extensive safety measures and protocols. Furthermore, as e-commerce continues to grow, the demand for rapid order processing has intensified, placing additional pressure on material handling systems.

Companies are increasingly seeking solutions that not only enhance speed but also ensure safety and reliability in their operations.

Advantages of Soft Robotics in Material Handling

Soft robotics offers a multitude of advantages that address the challenges faced in material handling. One of the most notable benefits is their ability to handle delicate items without causing damage. Soft robots are designed with compliant materials that can conform to the shape of the objects they manipulate, distributing forces evenly and minimizing the risk of breakage.

This capability is particularly valuable in industries such as food processing, pharmaceuticals, and electronics, where product integrity is paramount. Moreover, soft robots are inherently safer for human workers. Their flexible structures reduce the likelihood of injury during interactions with humans or other equipment.

This safety feature allows for more collaborative environments where humans and robots can work side by side without the need for extensive safety barriers. Additionally, soft robotics can be programmed to adapt their grip strength based on the object being handled, further enhancing safety and efficiency in operations. This adaptability not only streamlines workflows but also fosters a more harmonious relationship between human operators and robotic systems.

Recent Developments in Soft Robotics Technology

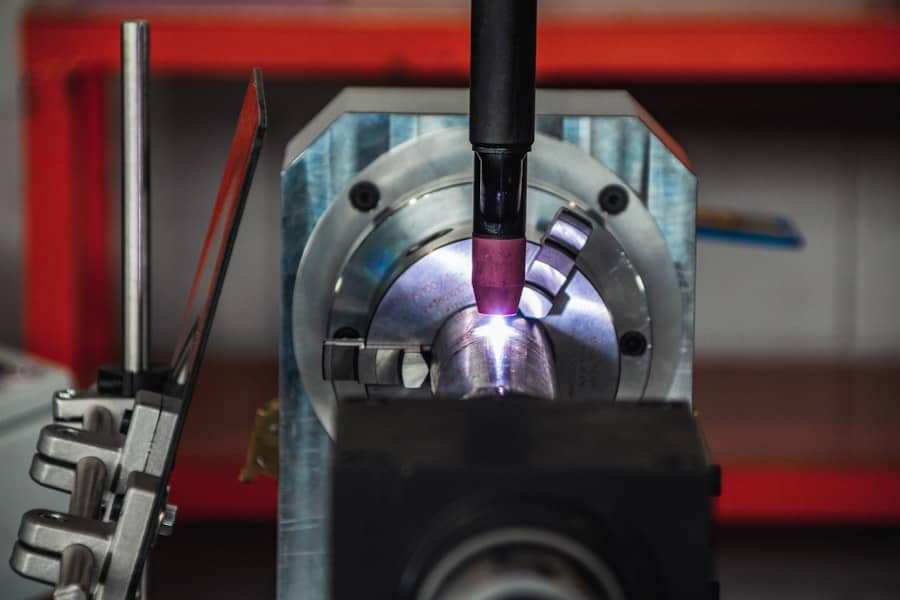

The field of soft robotics has witnessed remarkable advancements in recent years, driven by innovations in materials science, control algorithms, and sensor technology. Researchers are exploring new materials such as silicone elastomers, hydrogels, and shape-memory alloys that enable soft robots to exhibit a range of movements and functionalities. These materials allow for the creation of actuators that can mimic biological movements, such as bending, stretching, and twisting, which are essential for effective manipulation of various objects.

In addition to material innovations, advancements in control systems have significantly enhanced the capabilities of soft robots. Machine learning algorithms are being integrated into soft robotic systems, enabling them to learn from their environment and improve their performance over time. For instance, soft robots equipped with vision systems can identify objects and adjust their handling strategies accordingly.

This level of intelligence allows for greater autonomy in material handling tasks, reducing reliance on human oversight and increasing overall efficiency.

Applications of Soft Robotics in Material Handling

Soft robotics is finding applications across a diverse array of sectors within material handling. In agriculture, soft robotic grippers are being used to harvest delicate fruits and vegetables without bruising or damaging them. These robots can adapt their grip based on the size and shape of the produce, ensuring optimal handling while minimizing waste.

Similarly, in the food industry, soft robots are employed for packaging tasks where gentle handling is crucial to maintain product quality. In warehousing and logistics, soft robotics is revolutionizing order fulfillment processes. Robots equipped with soft grippers can navigate through crowded aisles and pick items from shelves with precision.

Their ability to handle a variety of package shapes makes them ideal for e-commerce operations where product diversity is high. Furthermore, soft robots can be designed to work collaboratively with traditional robotic systems or human workers, enhancing overall productivity in material handling environments.

Future Trends and Innovations in Soft Robotics

As research in soft robotics continues to evolve, several trends are emerging that promise to shape the future of this field. One significant trend is the integration of artificial intelligence (AI) into soft robotic systems. By leveraging AI algorithms, these robots will be able to analyze their surroundings in real-time, make decisions based on sensory input, and adapt their actions accordingly.

This level of intelligence will enable soft robots to perform complex tasks autonomously while ensuring safety and efficiency.

Researchers are studying various organisms to understand how they achieve remarkable feats of movement and manipulation using soft structures.

For example, octopuses possess unique abilities to grasp objects with their flexible arms; replicating these mechanisms could lead to breakthroughs in soft robotic design. Additionally, advancements in 3D printing technology are allowing for rapid prototyping of soft robotic components, enabling faster iterations and more innovative designs.

Impact of Soft Robotics on Material Handling Industry

The introduction of soft robotics into the material handling industry is poised to have a transformative impact on operations across various sectors. By enhancing efficiency and reducing damage during handling processes, companies can expect significant cost savings over time. The ability to automate delicate tasks not only streamlines workflows but also frees up human workers to focus on more complex responsibilities that require critical thinking and problem-solving skills.

Moreover, the safety benefits associated with soft robotics cannot be overstated. As these systems become more prevalent in warehouses and manufacturing facilities, the risk of workplace injuries is likely to decrease significantly. This shift towards safer working environments will not only improve employee morale but also reduce costs associated with worker compensation claims and training programs focused on safety protocols.

Conclusion and Future Outlook

The future outlook for soft robotics in material handling is bright as technological advancements continue to unfold at a rapid pace. The integration of AI, bio-inspired designs, and innovative materials will further enhance the capabilities of soft robots, making them indispensable tools in modern supply chains. As industries increasingly recognize the value of these adaptable systems, investment in research and development will likely accelerate.

By addressing current challenges such as safety concerns and the need for delicate handling, these innovative systems are set to redefine operational standards within the material handling industry. As we move forward into an era characterized by automation and intelligent systems, soft robotics will undoubtedly play a pivotal role in shaping the future landscape of material handling operations worldwide.

In a recent article on project management software, the importance of utilizing technology to streamline processes and improve efficiency in various industries was highlighted. This aligns with the advancements in soft robotics discussed in the article on The Future of Soft Robotics in Material Handling Applications. As companies continue to invest in innovative solutions like project management software and soft robotics, the potential for increased productivity and cost savings in material handling applications becomes even more promising.

FAQs

What is soft robotics?

Soft robotics is a subfield of robotics that focuses on the design and development of robots using soft and flexible materials, such as elastomers and polymers, as opposed to traditional rigid materials like metals and plastics.

What are material handling applications?

Material handling applications involve the movement, storage, control, and protection of materials and products throughout the manufacturing, distribution, consumption, and disposal processes. This includes tasks such as picking, packing, sorting, and transporting items in warehouses and logistics facilities.

How can soft robotics be used in material handling applications?

Soft robotics can be used in material handling applications to improve the manipulation and transportation of delicate or irregularly shaped objects. Soft robots can adapt to the shape and fragility of the items they handle, reducing the risk of damage and improving overall efficiency.

What are the advantages of using soft robotics in material handling?

Some advantages of using soft robotics in material handling applications include improved dexterity and flexibility, enhanced safety for human-robot interaction, and the ability to handle a wider range of objects compared to traditional rigid robots.

What are the challenges of implementing soft robotics in material handling applications?

Challenges of implementing soft robotics in material handling applications include the need for advanced control and sensing technologies, as well as the development of durable and reliable soft materials that can withstand the demands of industrial environments.

What is the future outlook for soft robotics in material handling applications?

The future of soft robotics in material handling applications looks promising, with ongoing research and development efforts focused on overcoming current challenges and expanding the capabilities of soft robots in industrial settings. As technology advances, we can expect to see increased adoption of soft robotics in material handling applications.