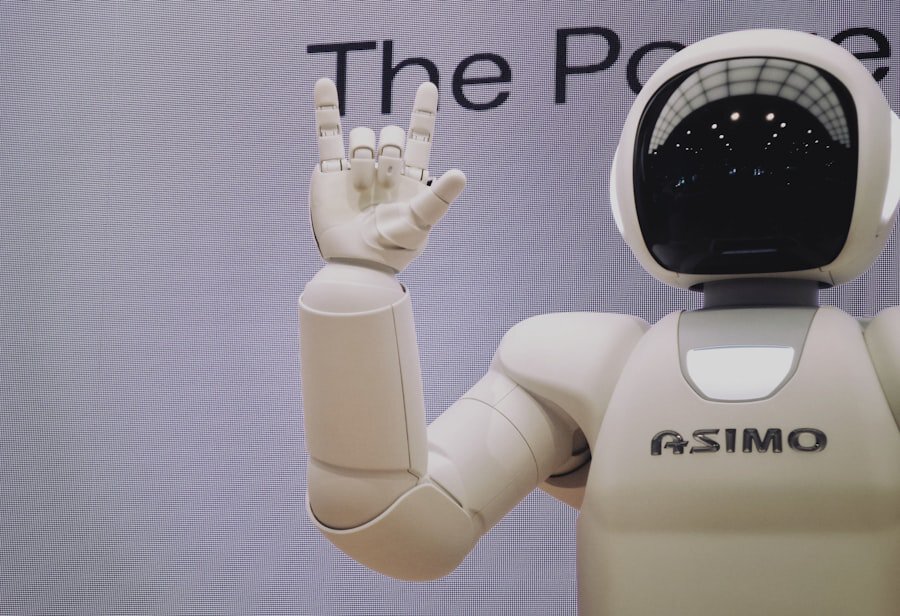

The landscape of advanced packaging solutions has undergone a significant transformation in recent years, driven by the integration of automation technologies. At the forefront of this evolution are robotic grippers, which serve as the critical interface between robotic systems and the products they handle. These devices are designed to mimic the dexterity and precision of human hands, enabling robots to perform a variety of tasks, from picking and placing items to assembling complex packaging structures.

The versatility of robotic grippers makes them indispensable in industries such as food and beverage, pharmaceuticals, electronics, and consumer goods, where efficiency and accuracy are paramount. Robotic grippers come in various forms, including mechanical, pneumatic, and electric types, each offering unique advantages tailored to specific applications. For instance, mechanical grippers utilize fingers or claws to grasp objects securely, while pneumatic grippers leverage air pressure to create a strong grip.

Electric grippers, on the other hand, provide precise control over gripping force and speed, making them ideal for delicate items. As the demand for faster production rates and higher quality standards continues to rise, the role of robotic grippers in advanced packaging solutions becomes increasingly critical. Their ability to adapt to different shapes and sizes of products enhances operational flexibility, allowing manufacturers to respond swiftly to changing market demands.

Key Takeaways

- Robotic grippers play a crucial role in advanced packaging solutions by automating the handling and manipulation of products.

- Current challenges in robotic grippers include the need for versatility in handling various shapes and sizes of products, as well as the requirement for gentle handling of delicate items.

- Innovations in robotic gripper technology, such as the development of adaptive grippers and soft robotic grippers, are addressing the challenges and improving the capabilities of robotic grippers.

- Robotic grippers have a significant impact on efficiency and cost-effectiveness in advanced packaging by increasing throughput, reducing labor costs, and minimizing product damage.

- The integration of robotic grippers with artificial intelligence and machine learning enables them to adapt to different products and environments, improving their performance and versatility.

Current Challenges in Robotic Grippers for Advanced Packaging

Despite the advancements in robotic gripper technology, several challenges persist that hinder their widespread adoption in advanced packaging applications. One of the primary issues is the difficulty in handling a diverse range of products with varying shapes, sizes, and materials. Traditional gripper designs often struggle to accommodate these variations, leading to inefficiencies and increased downtime during production.

For example, a gripper optimized for handling rigid boxes may not perform well when tasked with picking up soft or irregularly shaped items, necessitating frequent adjustments or replacements. Another significant challenge is the need for enhanced sensitivity and feedback mechanisms in robotic grippers. In many packaging scenarios, the ability to apply the right amount of force is crucial to prevent damage to fragile products.

This limitation can result in either excessive force that damages products or insufficient grip that leads to dropped items. As manufacturers strive for higher quality standards and reduced waste, addressing these challenges is essential for improving the reliability and effectiveness of robotic grippers in advanced packaging environments.

Innovations in Robotic Gripper Technology

The field of robotic gripper technology is witnessing a wave of innovations aimed at overcoming existing challenges and enhancing performance. One notable advancement is the development of soft robotics, which utilizes flexible materials to create grippers that can conform to the shape of various objects. Soft grippers are particularly effective in handling delicate items such as fruits or glass containers, where traditional rigid grippers may cause damage.

By mimicking the natural grasping motion of human hands, soft robotic grippers can provide a gentler touch while maintaining a secure hold on products. Additionally, advancements in sensor technology are playing a pivotal role in improving the functionality of robotic grippers. The integration of force sensors and tactile feedback systems allows grippers to adjust their grip strength dynamically based on the characteristics of the object being handled.

For instance, a gripper equipped with pressure sensors can detect when it is gripping a fragile item too tightly and automatically reduce its force to prevent breakage. This level of adaptability not only enhances product safety but also minimizes waste and rework in packaging operations.

Impact of Robotic Grippers on Efficiency and Cost-effectiveness in Advanced Packaging

The implementation of robotic grippers in advanced packaging solutions has a profound impact on operational efficiency and cost-effectiveness. By automating repetitive tasks such as picking, sorting, and packing, companies can significantly reduce labor costs while increasing throughput. For example, a packaging line that previously relied on manual labor for product handling can achieve higher output rates with robotic systems equipped with advanced grippers.

This shift not only accelerates production cycles but also allows human workers to focus on more complex tasks that require cognitive skills. Moreover, robotic grippers contribute to cost savings through improved accuracy and reduced product damage. In traditional packaging processes, human error can lead to misaligned packages or damaged goods, resulting in costly returns and waste.

Robotic grippers, with their precision and consistency, minimize these risks by ensuring that products are handled correctly every time. This reliability translates into lower operational costs and enhanced customer satisfaction, as businesses can deliver high-quality products without incurring additional expenses related to errors or defects.

Integration of Robotic Grippers with Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) technologies with robotic grippers is revolutionizing advanced packaging solutions by enabling smarter decision-making processes. AI algorithms can analyze vast amounts of data from production lines to optimize gripping strategies based on real-time conditions. For instance, machine learning models can predict which types of products are likely to be handled next based on historical data, allowing robotic systems to adjust their gripping techniques accordingly.

Furthermore, AI-powered vision systems can enhance the capabilities of robotic grippers by providing them with the ability to identify and classify objects autonomously. This capability is particularly beneficial in environments where products may vary significantly from one batch to another. By utilizing computer vision algorithms, robotic grippers can determine the optimal grip configuration for each item, ensuring efficient handling without manual intervention.

This level of automation not only streamlines operations but also reduces the likelihood of errors associated with human oversight.

Future Trends and Developments in Robotic Grippers for Advanced Packaging

As technology continues to evolve, several trends are emerging that will shape the future of robotic grippers in advanced packaging solutions. One prominent trend is the increasing focus on sustainability and eco-friendly practices within the packaging industry. Manufacturers are seeking ways to reduce waste and minimize their environmental footprint, prompting innovations in gripper design that utilize recyclable materials or energy-efficient mechanisms.

For example, lightweight materials may be employed in gripper construction to reduce energy consumption during operation. Another trend is the growing demand for collaborative robots (cobots) that work alongside human operators in packaging environments. Cobots equipped with advanced grippers can assist workers by taking over repetitive tasks while allowing humans to engage in more complex activities that require creativity and problem-solving skills.

This collaborative approach not only enhances productivity but also fosters a safer work environment by reducing the physical strain on human workers.

Potential Applications of Robotic Grippers in Advanced Packaging Solutions

The versatility of robotic grippers opens up a wide array of potential applications across various sectors within advanced packaging solutions. In the food industry, for instance, robotic grippers can be employed for tasks such as sorting fruits and vegetables based on size or ripeness before packaging them for distribution. The gentle handling capabilities of soft robotic grippers make them particularly suitable for this application, ensuring that delicate produce remains intact during processing.

In the pharmaceutical sector, robotic grippers play a crucial role in automating the packaging of medications and medical devices. With stringent regulations governing product safety and accuracy, the precision offered by robotic systems equipped with advanced grippers is invaluable. These systems can efficiently handle vials, syringes, and blister packs while maintaining compliance with industry standards.

Additionally, as e-commerce continues to grow, robotic grippers are increasingly being utilized in fulfillment centers to streamline order picking and packing processes.

The Role of Robotic Grippers in Shaping the Future of Advanced Packaging

Robotic grippers are poised to play a transformative role in shaping the future of advanced packaging solutions across various industries. Their ability to enhance efficiency, reduce costs, and improve product handling makes them an essential component of modern manufacturing processes.

The ongoing development of robotic gripper technology will not only address current challenges but also pave the way for new applications that were previously unimaginable. As businesses strive for greater sustainability and efficiency in their operations, robotic grippers will undoubtedly remain at the forefront of this evolution, driving advancements that will redefine how products are packaged and delivered in an increasingly competitive marketplace.

In addition to exploring the future of robotic grippers in advanced packaging solutions, it is also important to consider the role of social media content creation in marketing strategies. A comprehensive guide on the best software for social media content creation can be found here. As companies continue to innovate and automate their processes, having the right tools for creating engaging social media content can be crucial for reaching a wider audience and staying competitive in the market.

FAQs

What are robotic grippers?

Robotic grippers are devices used in robotics to grasp and manipulate objects. They are designed to mimic the function of a human hand and are used in various industries for tasks such as pick-and-place operations, assembly, and packaging.

What is the role of robotic grippers in advanced packaging solutions?

Robotic grippers play a crucial role in advanced packaging solutions by enabling automation and precision in the handling and packaging of products. They are used to pick, place, and manipulate items in packaging processes, improving efficiency and reducing the risk of damage to delicate or sensitive products.

What are the different types of robotic grippers used in advanced packaging solutions?

There are several types of robotic grippers used in advanced packaging solutions, including pneumatic grippers, electric grippers, and vacuum grippers. Each type has its own unique features and advantages, allowing for flexibility in handling different types of products and packaging materials.

What are the benefits of using robotic grippers in advanced packaging solutions?

Using robotic grippers in advanced packaging solutions offers several benefits, including increased speed and efficiency, improved accuracy and consistency, reduced labor costs, and enhanced safety in the packaging process. Additionally, robotic grippers can handle a wide range of products and packaging materials, making them versatile for various packaging applications.

How are robotic grippers expected to evolve in the future of advanced packaging solutions?

In the future, robotic grippers are expected to continue evolving with advancements in technology, such as the integration of artificial intelligence and machine learning for improved object recognition and handling. Additionally, there may be developments in the design and materials used for robotic grippers to enhance their capabilities and adaptability to different packaging requirements.