Molecular manufacturing represents a paradigm shift in the way we conceive of production and material creation. At its core, it involves the precise manipulation of molecules to construct complex structures and materials at the nanoscale. This technology leverages the principles of chemistry and physics to enable the assembly of materials atom by atom or molecule by molecule, leading to unprecedented levels of precision and efficiency.

Self-assembly, a key component of molecular manufacturing, refers to the process by which molecules spontaneously organize into structured arrangements without external guidance. This phenomenon is observed in nature, such as in the formation of cellular membranes or the intricate patterns of proteins, and is being harnessed in various technological applications. The implications of molecular manufacturing and self-assembly are vast, promising to revolutionize industries ranging from pharmaceuticals to electronics.

By enabling the creation of materials with tailored properties, these technologies could lead to innovations that enhance performance, reduce waste, and lower costs. The ability to design and fabricate materials at the molecular level opens up new avenues for research and development, allowing scientists and engineers to explore previously unattainable functionalities. As we delve deeper into this field, it becomes essential to understand both the current advancements and the potential challenges that lie ahead.

Key Takeaways

- Molecular manufacturing and self-assembly enable precise construction of materials at the molecular level.

- Current advancements have led to applications in medicine, electronics, and materials science.

- These technologies have the potential to revolutionize industries by improving efficiency and creating novel products.

- Ethical concerns and technical challenges must be addressed to ensure safe and responsible development.

- Future innovations and increased collaboration will drive regulatory frameworks and investment in this emerging field.

Current Applications and Advancements in Molecular Manufacturing

In recent years, molecular manufacturing has made significant strides across various sectors. One of the most notable applications is in the field of nanomedicine, where researchers are developing drug delivery systems that utilize nanoparticles to target specific cells or tissues. For instance, liposomes—spherical vesicles composed of lipid bilayers—are being engineered to encapsulate therapeutic agents and release them in a controlled manner.

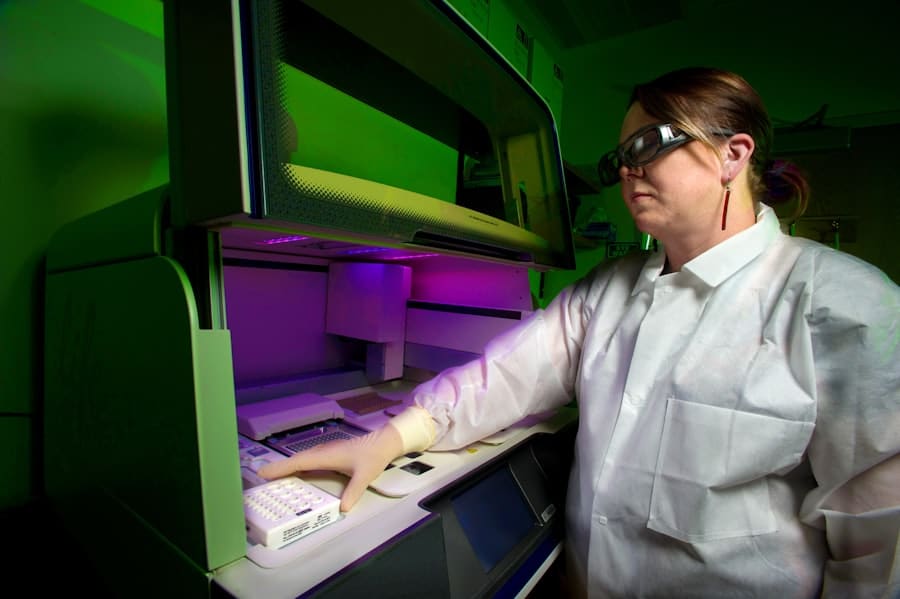

This targeted approach not only enhances the efficacy of treatments but also minimizes side effects, showcasing the potential of molecular manufacturing in improving patient outcomes. Another area where molecular manufacturing is making waves is in electronics. The miniaturization of components has reached a point where traditional manufacturing techniques struggle to keep pace with the demand for smaller, more efficient devices.

Molecular manufacturing techniques, such as bottom-up assembly, allow for the creation of nanoscale transistors and circuits that can significantly enhance computing power while reducing energy consumption. For example, researchers have successfully demonstrated the fabrication of single-molecule transistors that operate at room temperature, paving the way for ultra-compact electronic devices that could revolutionize computing and data storage.

Potential Impact of Molecular Manufacturing on Various Industries

The potential impact of molecular manufacturing extends far beyond healthcare and electronics; it has the capacity to transform numerous industries by enabling the creation of advanced materials with unique properties. In the field of materials science, for instance, molecular manufacturing can lead to the development of lightweight yet incredibly strong materials, such as carbon nanotubes or graphene-based composites. These materials could find applications in aerospace, automotive, and construction industries, where strength-to-weight ratios are critical for performance and efficiency.

Moreover, molecular manufacturing could play a pivotal role in addressing global challenges such as climate change and resource scarcity. By facilitating the production of energy-efficient materials and devices, this technology could contribute to the development of sustainable solutions. For example, solar cells manufactured at the molecular level could achieve higher efficiencies and lower production costs, making renewable energy sources more accessible.

Additionally, molecular manufacturing could enable the recycling of materials at a molecular level, allowing for a circular economy where waste is minimized, and resources are reused effectively.

Challenges and Ethical Considerations in Molecular Manufacturing

Despite its promising potential, molecular manufacturing faces several challenges that must be addressed to realize its full capabilities. One significant hurdle is the complexity involved in controlling molecular interactions during the assembly process. Achieving precise control over molecular arrangements requires a deep understanding of chemistry and physics, as well as advanced techniques for monitoring and manipulating these interactions.

Researchers are actively exploring various approaches, such as DNA origami and programmable self-assembly, to overcome these challenges and improve the reliability of molecular manufacturing processes. Ethical considerations also loom large in discussions surrounding molecular manufacturing. The ability to manipulate matter at such a fundamental level raises questions about safety, security, and environmental impact.

For instance, the potential for creating novel materials or organisms could lead to unintended consequences if not carefully regulated. Additionally, there are concerns about intellectual property rights and access to these technologies; ensuring equitable distribution and preventing monopolization will be crucial as molecular manufacturing becomes more prevalent. Engaging in open dialogue among scientists, policymakers, and ethicists will be essential to navigate these complex issues responsibly.

Future Opportunities and Innovations in Self-Assembly Technologies

| Metric | Current Status | Projected Status (2030) | Notes |

|---|---|---|---|

| Precision of Molecular Assembly | Nanometer scale (1-10 nm) | Sub-nanometer scale (0.1-1 nm) | Advances in atomic manipulation and control techniques |

| Manufacturing Speed | Micrometers per hour | Millimeters per hour | Improved automation and parallel assembly processes |

| Material Diversity | Limited to select polymers and simple molecules | Wide range including complex biomolecules and hybrid materials | Integration of biological and synthetic components |

| Self-Assembly Efficiency | 50-70% yield | 90-95% yield | Enhanced control over environmental conditions and molecular design |

| Cost per Unit | High (specialized equipment and materials) | Moderate to low (scalable production) | Economies of scale and improved manufacturing techniques |

| Applications | Experimental and niche industrial uses | Broad applications in medicine, electronics, and materials science | Expansion driven by improved reliability and cost-effectiveness |

| Environmental Impact | Moderate (energy-intensive processes) | Low (green manufacturing and biodegradable materials) | Focus on sustainability and reduced waste |

The future of self-assembly technologies holds immense promise for innovation across various fields. Researchers are exploring new materials and methods that enhance self-assembly processes, leading to more efficient and versatile applications. For example, advances in biomimetic materials—those inspired by natural processes—are paving the way for self-assembling systems that can adapt to their environment or respond to external stimuli.

Such materials could be utilized in smart textiles that change properties based on temperature or humidity or in responsive drug delivery systems that release medication only when triggered by specific biological signals. Moreover, integrating artificial intelligence (AI) with self-assembly technologies presents exciting opportunities for optimization and design. Machine learning algorithms can analyze vast datasets to identify patterns and predict outcomes in self-assembly processes, enabling researchers to design more effective systems with greater precision.

This synergy between AI and molecular manufacturing could accelerate the development of new materials and applications, driving innovation across industries while enhancing our understanding of complex molecular interactions.

Regulatory and Policy Implications for Molecular Manufacturing

As molecular manufacturing technologies advance, regulatory frameworks must evolve to address the unique challenges they present. Policymakers face the task of creating guidelines that ensure safety while fostering innovation. This includes establishing standards for testing and evaluating new materials produced through molecular manufacturing processes.

Regulatory bodies will need to collaborate with scientists and industry stakeholders to develop comprehensive frameworks that balance public safety with technological advancement. Additionally, international cooperation will be vital in addressing the global implications of molecular manufacturing. As these technologies transcend borders, harmonizing regulations across countries will help prevent discrepancies that could hinder progress or lead to unethical practices.

Establishing international agreements on research practices, intellectual property rights, and environmental standards will be crucial in promoting responsible development while ensuring that the benefits of molecular manufacturing are shared globally.

Collaboration and Investment in Research and Development for Molecular Manufacturing

The advancement of molecular manufacturing relies heavily on collaboration between academia, industry, and government entities. Interdisciplinary research initiatives that bring together chemists, engineers, biologists, and computer scientists can foster innovative solutions to complex challenges in this field. Collaborative projects can leverage diverse expertise to explore new materials, refine manufacturing processes, and develop applications that address real-world problems.

Investment in research and development is equally critical for driving progress in molecular manufacturing. Public funding agencies and private investors must recognize the transformative potential of these technologies and allocate resources accordingly. Initiatives such as grants for interdisciplinary research projects or partnerships between universities and industry can catalyze breakthroughs that propel molecular manufacturing forward.

Furthermore, fostering an entrepreneurial ecosystem that supports startups focused on molecular manufacturing can lead to rapid advancements and commercialization of innovative solutions.

The Promising Future of Molecular Manufacturing and Self-Assembly

The landscape of molecular manufacturing and self-assembly is rich with potential for innovation across various sectors. As we continue to explore this frontier, it is essential to navigate the challenges thoughtfully while embracing opportunities for collaboration and investment. The future holds exciting possibilities for creating advanced materials that can address pressing global issues while enhancing our quality of life.

By fostering responsible development through regulatory frameworks and ethical considerations, we can harness the power of molecular manufacturing to shape a sustainable future that benefits society as a whole.

In exploring the advancements in molecular manufacturing and self-assembly, it’s interesting to consider how these technologies might influence various industries, including electronics. For instance, the article on choosing your child’s first smartphone provides insights into the evolving landscape of mobile technology, which could be significantly impacted by innovations in materials science and manufacturing processes.