The integration of robots into industrial workspaces has evolved from a mere concept to a practical reality, fundamentally transforming how tasks are performed across various sectors. Human-robot collaboration (HRC) represents a paradigm shift where robots and humans work side by side, leveraging each other’s strengths to enhance productivity and efficiency. This collaboration is not limited to traditional manufacturing environments; it extends to logistics, healthcare, and even agriculture, showcasing the versatility of robotic applications.

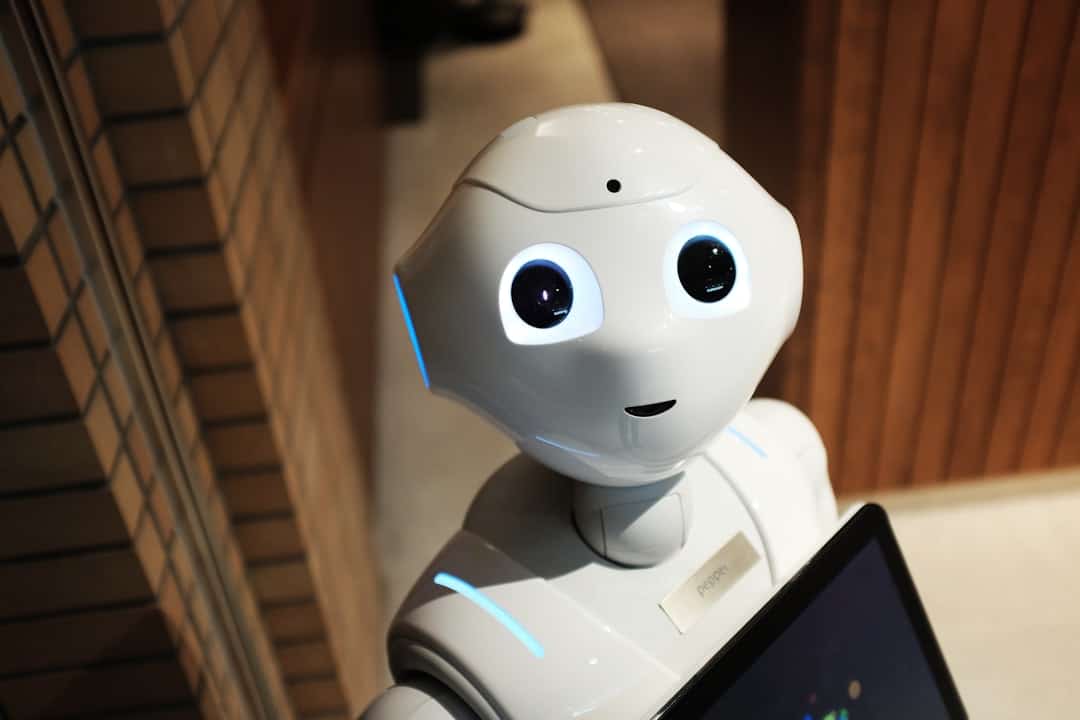

The rise of collaborative robots, or cobots, designed specifically to work alongside humans, has made this integration more feasible and safe, allowing for a more harmonious coexistence in the workplace. As industries strive for greater efficiency and adaptability in an increasingly competitive landscape, the role of HRC becomes ever more critical. The ability to combine human creativity and problem-solving skills with the precision and endurance of robots opens up new avenues for innovation.

For instance, in automotive manufacturing, robots can handle repetitive tasks such as welding or painting, while human workers focus on quality control and complex assembly processes. This synergy not only enhances operational efficiency but also fosters a more engaging work environment where human workers can contribute their unique skills.

Key Takeaways

- Human-robot collaboration in industrial workspaces is becoming increasingly common as technology advances and the need for efficiency grows.

- Current challenges and limitations of human-robot collaboration include safety concerns, lack of standardization, and the need for improved communication between humans and robots.

- Advancements in robotics and automation technologies, such as artificial intelligence and machine learning, are improving the capabilities and flexibility of robots in industrial settings.

- Human-robot collaboration has the potential to significantly impact productivity and efficiency in industrial workspaces by automating repetitive tasks and allowing humans to focus on more complex and creative work.

- Ethical and safety considerations in human-robot collaboration are crucial, as they involve the well-being of both humans and robots, and require careful planning and implementation of safety protocols.

Current Challenges and Limitations of Human-Robot Collaboration

Technological Barriers to Adoption

Despite the promising potential of human-robot collaboration, several challenges and limitations hinder its widespread adoption in industrial settings. One significant barrier is the technological gap that exists between advanced robotics systems and the existing infrastructure in many factories. Many organizations still rely on legacy systems that are not compatible with modern robotic technologies.

Integration Challenges and Safety Concerns

This incompatibility can lead to increased costs and complexity when attempting to integrate new robotic solutions into established workflows.

While cobots are designed with safety features to minimize risks, the unpredictable nature of human behavior can lead to accidents.

Safety Protocols and Monitoring Systems

Ensuring that both humans and robots can operate safely together requires rigorous safety protocols and continuous monitoring systems, which can be resource-intensive to implement.

Advancements in Robotics and Automation Technologies

Recent advancements in robotics and automation technologies have significantly enhanced the capabilities of collaborative robots. Innovations in artificial intelligence (AI) and machine learning have enabled robots to learn from their environments and adapt their behaviors accordingly. For instance, AI-driven vision systems allow robots to recognize objects and navigate complex environments with greater accuracy.

This capability is particularly beneficial in dynamic industrial settings where the layout may change frequently or where tasks require real-time adjustments based on varying conditions. Additionally, improvements in sensor technology have made it possible for robots to detect human presence and respond appropriately. Proximity sensors, force sensors, and advanced cameras enable cobots to operate safely alongside human workers by slowing down or stopping their movements when a person is nearby.

These advancements not only enhance safety but also improve the overall efficiency of operations by allowing for more fluid interactions between humans and robots.

Impact of Human-Robot Collaboration on Productivity and Efficiency

The impact of human-robot collaboration on productivity and efficiency is profound and multifaceted. By automating repetitive and physically demanding tasks, organizations can free up human workers to focus on higher-value activities that require critical thinking and creativity. For example, in a warehouse setting, robots can handle inventory management tasks such as picking and packing items, while human workers can concentrate on customer service or strategic planning.

This division of labor not only boosts productivity but also enhances job satisfaction among employees who can engage in more meaningful work. Furthermore, the implementation of HRC can lead to significant reductions in operational costs. By optimizing workflows through the strategic deployment of robots, companies can achieve faster turnaround times and improved output quality.

A study conducted by the International Federation of Robotics found that companies that adopted collaborative robotics experienced productivity increases of up to 30%.

Ethical and Safety Considerations in Human-Robot Collaboration

As industries increasingly embrace human-robot collaboration, ethical and safety considerations must be at the forefront of discussions surrounding this technology. One major ethical concern is the potential displacement of human workers due to automation. While HRC aims to enhance productivity, there is a fear that it may lead to job losses in certain sectors.

It is crucial for organizations to approach this transition thoughtfully, ensuring that workers are retrained for new roles that leverage their unique skills rather than being replaced entirely. Safety is another paramount concern in HRC environments. The introduction of robots into workplaces necessitates comprehensive safety protocols to protect both human workers and equipment.

Organizations must invest in training programs that educate employees about safe practices when working alongside robots. Additionally, regulatory bodies need to establish clear guidelines regarding the safe operation of collaborative robots to mitigate risks associated with their use.

Training and Education for Human-Robot Collaboration

Equipping Employees with Essential Skills

As robots become increasingly integrated into industrial processes, employees must be equipped with the necessary skills to work effectively alongside them. This includes understanding how to operate robotic systems, troubleshoot issues, and collaborate with machines in a way that maximizes productivity.

Emergence of Robotics-Focused Education

Educational institutions are recognizing the importance of incorporating robotics into their curricula. Programs focused on robotics engineering, automation technology, and AI are emerging at universities and technical schools worldwide. These programs aim to produce a workforce that is not only proficient in operating robotic systems but also capable of innovating new solutions that enhance human-robot collaboration.

Investing in Ongoing Training Initiatives

Furthermore, companies are investing in ongoing training initiatives for their employees to ensure they remain competitive in an evolving job market.

Future Trends and Predictions for Human-Robot Collaboration in Industrial Workspaces

Looking ahead, several trends are likely to shape the future of human-robot collaboration in industrial workspaces. One prominent trend is the increasing use of AI-driven analytics to optimize HRC processes. By leveraging data collected from robotic systems and human interactions, organizations can gain insights into workflow efficiencies and identify areas for improvement.

Predictive analytics may also play a role in anticipating maintenance needs for robotic systems, reducing downtime and enhancing overall productivity. Another trend is the growing emphasis on customization and flexibility in robotic solutions. As industries face fluctuating demands and diverse product lines, there will be a greater need for adaptable robotic systems that can be easily reprogrammed or reconfigured for different tasks.

This flexibility will enable organizations to respond more swiftly to market changes while maintaining high levels of efficiency.

The Potential of Human-Robot Collaboration for the Future of Industrial Workspaces

The potential of human-robot collaboration in industrial workspaces is vast and continues to expand as technology advances. By harnessing the strengths of both humans and robots, organizations can create more efficient, productive, and innovative environments that benefit all stakeholders involved. As challenges related to safety, ethics, training, and technology integration are addressed, the future of HRC looks promising.

In this evolving landscape, it is essential for industries to remain proactive in adapting to these changes while prioritizing the well-being of their workforce. By fostering a culture of collaboration between humans and robots, companies can unlock new levels of performance that were previously unattainable. The journey toward fully realizing the potential of human-robot collaboration is just beginning, but its implications for the future of work are profound and far-reaching.

In a recent article discussing The Future of Human-Robot Collaboration in Industrial Workspaces, it is interesting to note the advancements in technology that are shaping the way we work alongside robots. For further insights into cutting-edge technology, check out this article on the best free software for voice recording. This article highlights the importance of utilizing innovative tools to enhance productivity and efficiency in various industries.

FAQs

What is human-robot collaboration in industrial workspaces?

Human-robot collaboration in industrial workspaces refers to the interaction and cooperation between humans and robots in a shared workspace. This collaboration involves tasks such as assembly, material handling, and quality control, where humans and robots work together to improve efficiency and productivity.

What are the benefits of human-robot collaboration in industrial workspaces?

The benefits of human-robot collaboration in industrial workspaces include increased productivity, improved safety, reduced ergonomic strain on workers, and the ability to handle complex tasks more efficiently. This collaboration also allows for the automation of repetitive and dangerous tasks, freeing up human workers to focus on more skilled and strategic activities.

What are the challenges of human-robot collaboration in industrial workspaces?

Challenges of human-robot collaboration in industrial workspaces include ensuring the safety of human workers when working alongside robots, integrating robots into existing workflows and processes, and addressing concerns about job displacement and the impact on the workforce. Additionally, there may be technical challenges related to programming and maintaining the robots.

What technologies are driving the future of human-robot collaboration in industrial workspaces?

Technologies such as advanced sensors, artificial intelligence, machine learning, and collaborative robots (cobots) are driving the future of human-robot collaboration in industrial workspaces. These technologies enable robots to work more autonomously, adapt to changing environments, and collaborate more effectively with human workers.

How will human-robot collaboration impact the future of industrial workspaces?

Human-robot collaboration is expected to transform industrial workspaces by improving efficiency, safety, and flexibility. It will also lead to the creation of new job roles focused on robot programming, maintenance, and supervision. Overall, human-robot collaboration is likely to lead to a more productive and competitive industrial sector.