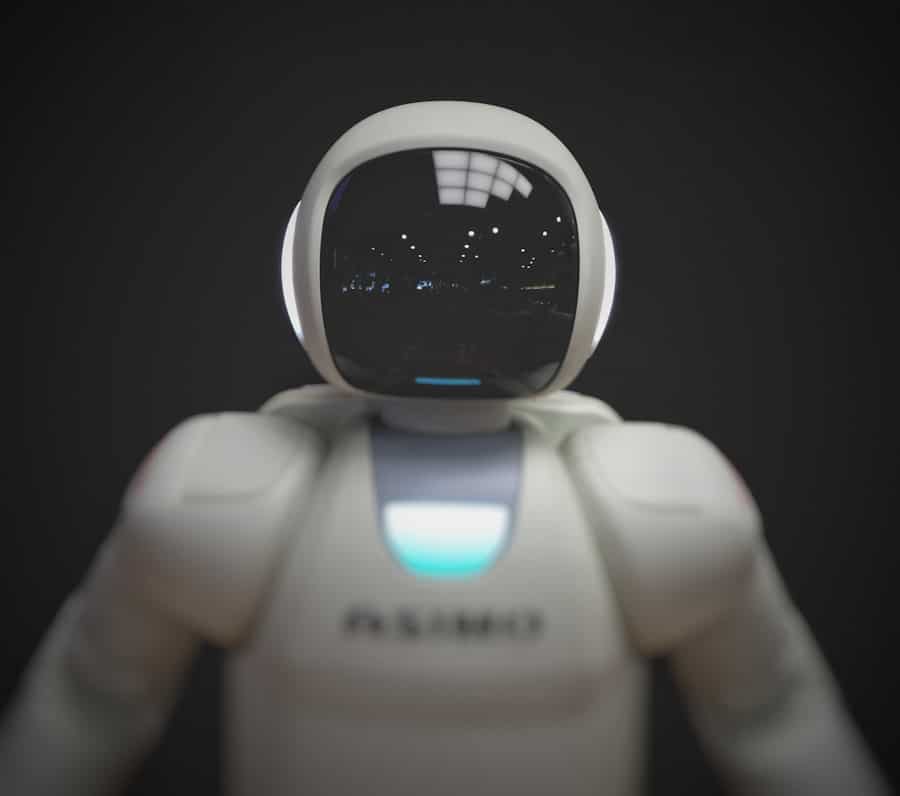

The integration of artificial intelligence (AI) into industrial robotics has revolutionized the manufacturing landscape, particularly in environments that pose significant hazards to human workers. AI-powered industrial robots are designed to perform complex tasks with precision and efficiency, leveraging machine learning algorithms and advanced sensors to adapt to their surroundings.

As industries increasingly adopt these intelligent systems, the potential for improved safety and operational efficiency becomes more pronounced. The rise of AI in robotics is not merely a trend; it represents a fundamental shift in how industries approach labor-intensive and hazardous tasks. Traditional industrial robots, while effective in repetitive tasks, lacked the cognitive capabilities to make real-time decisions based on environmental changes.

In contrast, AI-powered robots can analyze vast amounts of data, learn from their experiences, and adjust their actions accordingly. This adaptability is crucial in hazardous environments where conditions can change rapidly, requiring immediate responses to ensure safety and efficiency. As we delve deeper into the challenges faced in these environments and the advancements made in AI-powered robotics, it becomes clear that this technology is poised to redefine the future of industrial operations.

Key Takeaways

- AI-powered industrial robotics are revolutionizing the manufacturing industry by combining artificial intelligence with robotics to automate and optimize processes.

- Hazardous environments present challenges such as extreme temperatures, high pressure, and toxic substances, making it dangerous for human workers to operate in these conditions.

- Advancements in AI-powered industrial robotics, such as machine learning and computer vision, have enabled robots to perform complex tasks and adapt to changing environments in hazardous settings.

- AI-powered industrial robotics are being used in hazardous environments for tasks such as inspection, maintenance, and handling of hazardous materials, improving efficiency and safety.

- Safety and risk management are crucial in the implementation of AI-powered industrial robotics in hazardous environments to ensure the protection of human workers and the environment.

Current Challenges in Hazardous Environments

Hazardous environments present a myriad of challenges that can compromise worker safety and operational efficiency. Industries such as mining, oil and gas extraction, chemical manufacturing, and nuclear power generation are fraught with risks that can lead to severe accidents, health issues, and even fatalities. For instance, workers in chemical plants may be exposed to toxic substances that can cause long-term health problems or immediate harm.

Similarly, in mining operations, the risk of cave-ins or exposure to harmful gases poses significant threats to human life. These challenges necessitate innovative solutions that can effectively manage risks while maintaining productivity. Moreover, the physical limitations of human workers in hazardous environments cannot be overlooked.

Humans are susceptible to fatigue, stress, and cognitive overload, which can impair decision-making and reaction times in critical situations. In contrast, AI-powered industrial robots can operate continuously without the need for breaks or rest, allowing them to perform tasks that would be too dangerous or exhausting for human workers. However, the implementation of these robots is not without its own set of challenges.

Issues such as high initial costs, the need for specialized training, and concerns about job displacement must be addressed to facilitate a smoother transition to AI-driven operations.

Advancements in AI-Powered Industrial Robotics

Recent advancements in AI technology have significantly enhanced the capabilities of industrial robots, making them more suitable for hazardous environments. One notable development is the incorporation of advanced sensors and computer vision systems that enable robots to perceive their surroundings with remarkable accuracy. These sensors can detect changes in temperature, pressure, and chemical composition, allowing robots to navigate complex environments safely.

For example, in a chemical processing plant, robots equipped with gas detection sensors can identify leaks or hazardous conditions and respond accordingly without endangering human workers. Machine learning algorithms have also played a pivotal role in advancing AI-powered robotics. These algorithms allow robots to learn from their experiences and improve their performance over time.

For instance, a robot tasked with handling hazardous materials can analyze past incidents to refine its handling techniques and minimize risks. Additionally, reinforcement learning enables robots to optimize their actions based on feedback from their environment, further enhancing their adaptability in unpredictable situations. As these technologies continue to evolve, the potential for AI-powered industrial robotics to operate safely and efficiently in hazardous environments expands exponentially.

Applications of AI-Powered Industrial Robotics in Hazardous Environments

AI-powered industrial robotics have found diverse applications across various sectors that operate in hazardous environments. In the oil and gas industry, for instance, drones equipped with AI capabilities are increasingly used for pipeline inspections and monitoring. These drones can traverse difficult terrains and access remote locations that would be perilous for human workers.

By utilizing high-resolution cameras and thermal imaging technology, they can detect leaks or structural weaknesses without exposing personnel to dangerous conditions. In the realm of nuclear power generation, AI-powered robots are employed for decommissioning tasks that involve handling radioactive materials. These robots can perform intricate operations such as dismantling equipment or cleaning contaminated areas while minimizing human exposure to radiation.

The use of robotic systems not only enhances safety but also accelerates the decommissioning process, which is often lengthy and complex due to regulatory requirements and safety protocols. Furthermore, in the mining sector, autonomous vehicles equipped with AI are being deployed for ore extraction and transportation, reducing the need for human presence in high-risk areas.

Safety and Risk Management in AI-Powered Industrial Robotics

Safety remains a paramount concern when integrating AI-powered robotics into hazardous environments. Effective risk management strategies must be established to ensure that these systems operate safely alongside human workers. One approach involves implementing rigorous testing protocols before deploying robots in real-world scenarios.

This includes simulating various hazardous conditions to evaluate how robots respond and adapt to potential dangers. By identifying weaknesses or vulnerabilities during testing phases, organizations can make necessary adjustments to enhance safety. Moreover, collaboration between human operators and AI-powered robots is essential for effective risk management.

Human oversight can provide an additional layer of safety by allowing operators to monitor robotic activities and intervene when necessary. For instance, in a chemical plant where robots handle toxic substances, human operators can oversee operations from a safe distance while maintaining control over critical decision-making processes. This collaborative approach not only enhances safety but also fosters trust between human workers and robotic systems.

Future Developments and Innovations in AI-Powered Industrial Robotics

The future of AI-powered industrial robotics is poised for remarkable developments as technology continues to advance at an unprecedented pace. One area of focus is the enhancement of collaborative robotics (cobots), which are designed to work alongside human operators safely. Future cobots will likely incorporate more sophisticated AI algorithms that enable them to understand human intentions better and respond accordingly.

This could lead to more intuitive interactions between humans and robots, enhancing overall productivity while ensuring safety. Another promising avenue for innovation lies in the integration of AI with Internet of Things (IoT) technologies. By connecting robots with IoT devices, organizations can create a comprehensive network that allows for real-time data sharing and analysis.

This interconnectedness will enable robots to make informed decisions based on a broader context of environmental conditions and operational parameters. For example, an AI-powered robot could receive data from IoT sensors monitoring air quality in a chemical plant and adjust its operations accordingly to minimize exposure risks.

Impact of AI-Powered Industrial Robotics on the Workforce

The introduction of AI-powered industrial robotics into hazardous environments has sparked discussions about its impact on the workforce. While some fear job displacement due to automation, it is essential to recognize that these technologies can also create new opportunities for workers.

This shift may lead to a demand for a more skilled workforce capable of managing advanced technologies. Moreover, the collaboration between humans and robots can enhance job satisfaction by reducing the physical toll associated with hazardous work environments. Workers may find greater fulfillment in roles that focus on strategic decision-making rather than performing repetitive or dangerous tasks.

Additionally, organizations that prioritize worker safety through automation may experience lower turnover rates and improved employee morale as workers feel valued and protected.

The Future of AI-Powered Industrial Robotics for Hazardous Environments

As industries continue to grapple with the challenges posed by hazardous environments, the role of AI-powered industrial robotics will become increasingly vital. The advancements made in this field not only promise enhanced safety but also improved operational efficiency across various sectors. By addressing current challenges through innovative solutions and fostering collaboration between humans and machines, organizations can create safer workplaces while maximizing productivity.

Looking ahead, the potential for further developments in AI technology will undoubtedly shape the future landscape of industrial operations. As we embrace these innovations, it is crucial to remain mindful of their implications on the workforce and ensure that transitions are managed thoughtfully. The journey toward fully integrating AI-powered robotics into hazardous environments is just beginning; however, it holds immense promise for transforming how industries operate while prioritizing safety and efficiency.

If you are interested in the latest advancements in technology, you may also want to check out this article on how to choose a laptop for video editing offers valuable tips and recommendations. Lastly, if you are curious about the world of digital art and collectibles, the article on NFT images provides insight into this emerging trend.

FAQs

What is AI-powered industrial robotics for hazardous environments?

AI-powered industrial robotics for hazardous environments refers to the use of advanced artificial intelligence (AI) technology to control robotic systems in environments that are dangerous or inaccessible to humans. These robots are designed to perform tasks such as inspection, maintenance, and repair in environments with high temperatures, radiation, or toxic chemicals.

How does AI-powered industrial robotics work in hazardous environments?

AI-powered industrial robotics use sensors, cameras, and other data-gathering tools to collect information about the environment. This data is then processed by AI algorithms to make decisions and control the robotic system. The robots can autonomously navigate and perform tasks in hazardous environments, reducing the risk to human workers.

What are the benefits of AI-powered industrial robotics for hazardous environments?

The use of AI-powered industrial robotics in hazardous environments can improve safety by reducing the need for human workers to enter dangerous areas. These robots can also increase efficiency and productivity by performing tasks more quickly and accurately than humans. Additionally, they can gather and analyze data to provide valuable insights for maintenance and operations.

What are some applications of AI-powered industrial robotics in hazardous environments?

AI-powered industrial robotics can be used in a variety of hazardous environments, including nuclear power plants, chemical processing facilities, and offshore oil and gas platforms. They can perform tasks such as inspecting equipment, cleaning up hazardous materials, and conducting repairs in areas that are too dangerous for human workers to access.

What are the challenges of using AI-powered industrial robotics in hazardous environments?

Challenges in using AI-powered industrial robotics in hazardous environments include the need for robust and reliable communication systems, as well as the development of AI algorithms that can adapt to unpredictable and dynamic environments. Additionally, ensuring the safety and security of these robotic systems is a critical consideration.