The assembly of flat-pack furniture, a hallmark of companies like IKEA, has long been a user experience marked by varying degrees of frustration, ingenuity, and occasional despair. The ubiquitous diagram-based instructions and the collection of often numerous, small components can transform a simple purchase into a weekend-long challenge. However, the advent of advanced robotics and automation is now presenting a potential paradigm shift, leading to discussions about “Robotic Furniture Assembly: The Future of IKEA?”

The Traditional Assembly Model: A Familiar Landscape

For decades, the model championed by IKEA and similar retailers has been built on a specific economic and logistical foundation. The flat-pack design, where furniture is disassembled for shipping, drastically reduces the volume of goods transported, leading to significant cost savings in warehousing and logistics. This cost reduction is then passed on to the consumer, making stylish and functional furniture more accessible. The act of assembly, while sometimes viewed as a chore, has also been marketed as a form of user empowerment, a DIY experience that fosters a sense of accomplishment.

The assembly process itself typically involves:

Components and Hardware

- Wooden panels and components: These form the structural elements of the furniture.

- Fasteners: A variety of screws, bolts, dowels, and cam locks are provided to connect these panels.

- Tools: While often limited to an Allen key, the user is generally expected to possess basic tools like a screwdriver.

The Instruction Manual

- Pictorial instructions: These rely on a series of diagrams to guide the user through each step, minimizing the need for language translation.

- Step-by-step progression: The instructions are designed to break down the assembly into manageable stages.

User Experience and Challenges

- Time commitment: Assembling larger or more complex items can require several hours.

- Dexterity and strength: Certain steps may demand a degree of physical strength and fine motor skills.

- Spatial reasoning: Interpreting diagrams and visualizing the final product can be challenging for some.

- Misinterpretation and errors: The reliance on visual cues can lead to mistakes, resulting in misaligned pieces or incorrectly installed hardware.

- Missing parts or damage: While infrequent, these issues can halt the assembly process entirely.

This model, despite its occasional drawbacks, has proven remarkably successful, enabling IKEA to become a global retail giant. The core idea is that by outsourcing the final assembly to the consumer, a significant operational cost is eliminated.

As the concept of robotic furniture assembly gains traction, it is intriguing to consider how advancements in technology are reshaping various industries. A related article that explores the impact of cutting-edge technology on consumer products is titled “The iPhone 14 Pro: Experience the Power of Pro.” This piece delves into the innovative features of the latest iPhone model and how it enhances user experience, much like how robotic assembly could revolutionize the way we interact with furniture. For more insights, you can read the article here: The iPhone 14 Pro: Experience the Power of Pro.

The Rise of Robotic Automation: A New Frontier

Robotics, once the domain of complex industrial manufacturing, is increasingly permeating various sectors. From autonomous vehicles to surgical robots, the capabilities of automated systems are expanding at an unprecedented rate. In the context of furniture assembly, this translates to the potential for machines to perform tasks that were previously exclusively human domains.

Evolution of Robotic Capabilities

- Industrial robots: Early robots were predominantly used in repetitive, heavy-duty tasks in factories.

- Cobots (Collaborative Robots): These robots are designed to work alongside humans, sharing workspaces and assisting with tasks. Their safety features and user-friendliness have made them more accessible.

- AI Integration: The integration of artificial intelligence allows robots to learn, adapt, and make decisions, moving beyond pre-programmed instructions.

- Computer Vision: Advanced cameras and sensors enable robots to “see” and interpret their environment, identify components, and assess the precision of their actions.

These advancements are not merely about replacing human labor; they are about enhancing efficiency, accuracy, and potentially creating new user experiences. Imagine a world where the frustration of a misaligned screw or a missing dowel is a relic of the past.

Potential Implementations of Robotic Furniture Assembly

The concept of robotic furniture assembly can manifest in several ways, each with its own set of advantages and logistical considerations. These implementations could operate at different points in the supply chain or directly interact with the consumer.

In-Store or Showroom Assembly

One immediate application of robotic assembly could be within IKEA’s own retail spaces.

Benefits:

- Enhanced customer experience: Customers could see furniture assembled in real-time, demystifying the process and building confidence in the product.

- Reduced assembly burden for customers: For those purchasing large items, the option of having them assembled on-site would eliminate the need for home assembly.

- Quality control: Robots can ensure precise assembly, reducing the likelihood of defects.

- Demonstration of technology: It would serve as a highly visible showcase of IKEA’s commitment to innovation.

Technologies involved:

- Articulated robots: These robotic arms, similar to those used in manufacturing, could be programmed to pick, place, and fasten components.

- Vision systems: Cameras and sensors would guide the robots, ensuring they select the correct parts and orient them properly.

- Automated part feeders: Systems to present components to the robots in an organized manner.

Customer-Facing Robotic Assembly Stations

Alternatively, robotic assistance could be offered directly to customers at the point of purchase or in designated assembly areas.

How it might work:

- “Assemble Your Own” with robot assistance: Customers would bring their flat-pack boxes to a station where robotic arms could guide them through the process or perform specific, challenging steps.

- Full robotic assembly for a fee: A more premium service where customers can opt to have their furniture fully assembled by robots before leaving the store.

Considerations:

- User interface design: Intuitive interfaces would be needed for customers to interact with the robotic systems.

- Footprint and infrastructure: Dedicated space would be required for these stations within stores.

- Cost of implementation and maintenance: The initial investment and ongoing upkeep of robotic systems.

At-Home Robotic Assembly Services

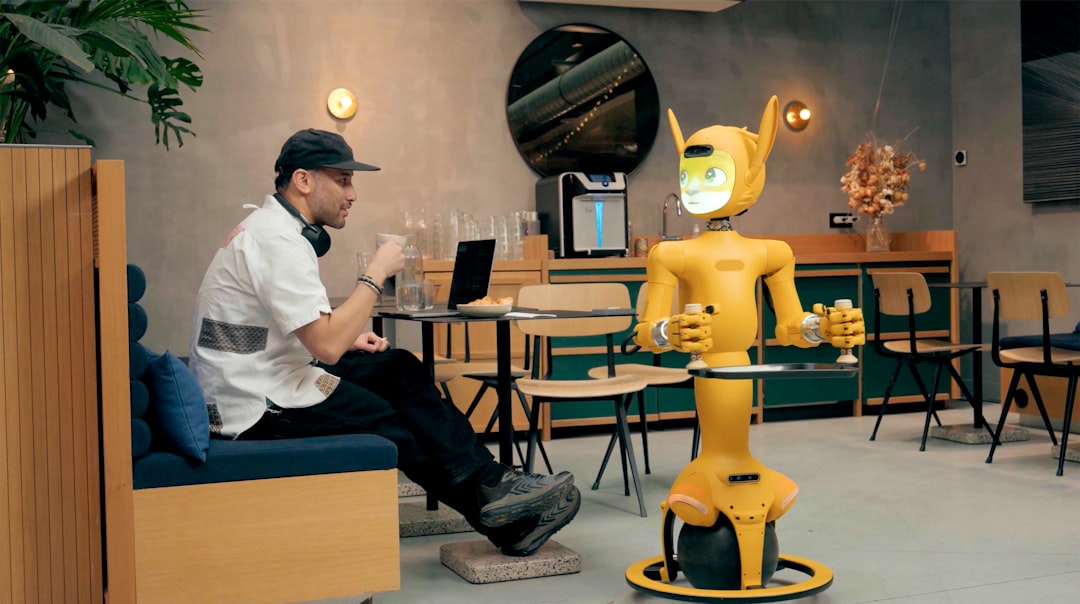

A more futuristic vision involves robots that could come to the customer’s home.

Dream scenario for consumers:

- On-demand assembly: A service where a technician, accompanied by a mobile robotic unit, arrives at the customer’s residence to assemble furniture.

- Mobile robotic units: Compact, versatile robots capable of navigating domestic spaces and performing assembly tasks.

Challenges:

- Mobility and maneuverability: Robots would need to navigate varied home environments, including stairs and tight spaces.

- Safety in domestic settings: Ensuring the robots operate safely around people and pets.

- Logistics and scheduling: Managing a fleet of mobile robotic assemblers.

- Regulatory hurdles: Potential safety and operational regulations for domestic robots.

Each of these implementations represents a step away from the traditional user-driven assembly model and raises pertinent questions about the evolving relationship between consumers, retailers, and technology.

Advantages of Robotic Furniture Assembly

The integration of robots into furniture assembly processes promises a range of benefits, addressing many of the pain points associated with traditional methods. These advantages extend beyond mere convenience, impacting efficiency, quality, and even inclusivity.

Increased Efficiency and Speed

Robots, unburdened by fatigue or the need for breaks, can perform assembly tasks with a consistent speed and rhythm. This translates to faster turnaround times for assembled products, both in manufacturing and potentially for customer orders. Imagine an assembly line operating with the unwavering precision of a metronome, each component clicking into place without hesitation.

Enhanced Precision and Quality

Human error is an inherent part of any manual task. Robots, guided by precise programming and advanced vision systems, can achieve a level of accuracy that is difficult for humans to consistently replicate. This means perfectly aligned pieces, correctly tightened fasteners, and a reduction in manufacturing defects. The end result is furniture that is not only assembled correctly but also built to last.

Reduced Physical Strain and Improved Safety

The physical demands of furniture assembly can be considerable, especially for larger items. Lifting heavy panels, maneuvering awkward pieces, and repeatedly using tools can lead to strain and injury. Robots can take on these strenuous tasks, protecting human workers from repetitive stress injuries and heavy lifting. This also contributes to a safer working environment overall, both in factories and potentially in future domestic applications.

Greater Accessibility and Inclusivity

The challenges of manual assembly can be a barrier for individuals with physical limitations, seniors, or those with limited technical aptitude. Robotic assembly solutions could democratize furniture ownership by removing these obstacles. For instance, a person who struggles with fine motor skills could still enjoy the convenience of flat-pack furniture without the personal assembly burden.

Cost Optimization (Potential)

While the initial investment in robotics can be substantial, in the long term, increased efficiency, reduced errors, and optimized labor allocation can lead to significant cost savings for manufacturers. For consumers, the savings could come in the form of reduced assembly service fees or the elimination of the need to purchase specialized tools. The cost-benefit analysis will, of course, depend on the specific implementation and scale.

These advantages paint a picture of a future where furniture assembly is less of a hurdle and more of a seamless part of the product experience.

As the concept of robotic furniture assembly gains traction, many are curious about how technology will reshape our living spaces, particularly with companies like IKEA at the forefront of innovation. A related article explores the advancements in technology that are paving the way for smarter home solutions, highlighting the potential of devices like the Samsung Galaxy Chromebook 4. For more insights on how these innovations can enhance our daily lives, you can read the full article here.

Challenges and Considerations for Implementation

Despite the compelling advantages, the widespread adoption of robotic furniture assembly is not without its hurdles. Several factors must be carefully considered and addressed for this future to become a reality. The path to robotic assembly is not a straight, unobstructed road.

Initial Investment and Scalability

The upfront cost of acquiring and integrating robotic systems is significant. This includes not only the robots themselves but also the necessary infrastructure, programming, and training. For companies like IKEA, which operate on massive scales, this investment would be substantial, requiring careful financial planning and a clear return on investment strategy. The ability to scale these robotic solutions across a global retail network is another critical challenge.

Complexity of Furniture Designs

While robots excel at repetitive tasks, the intricate and varied designs of modern furniture can pose a challenge. Robots need to be programmed to handle a wide range of component shapes, sizes, and assembly sequences. The introduction of new product lines or design variations would require re-programming or re-configuration of the robotic systems, adding to the cost and complexity. Imagine a robot needing to learn a new dance with every slightly different chair design.

Integration with Existing Infrastructure

Many manufacturing facilities and retail environments are already established, with existing workflows and layouts. Integrating new robotic systems into these existing structures requires careful planning to minimize disruption and maximize efficiency. This might involve re-designing factory floors, adjusting logistics, or retrofitting retail spaces.

Software and Programming Sophistication

Developing the sophisticated software required to control these robots is a major undertaking. This includes not only the basic commands for picking and placing but also advanced algorithms for error detection, adaptive assembly, and user interaction. Continuous updates and maintenance of this software would also be crucial.

Human Oversight and Maintenance

Even with advanced automation, human oversight remains essential. Skilled technicians will be needed to monitor the robotic systems, perform maintenance, troubleshoot issues, and handle exceptions that the robots cannot manage. The role of humans will shift from direct assembly to supervision and technical support.

Consumer Acceptance and Trust

While many consumers may appreciate the convenience of robotic assembly, there might be a degree of skepticism or apprehension about relinquishing control of the assembly process entirely. Building trust and demonstrating the reliability and safety of robotic assembly will be key to broad consumer acceptance. Some may miss the tactile satisfaction of building something themselves.

Ethical and Social Implications

The widespread adoption of robotic assembly could have implications for employment. While new jobs in robotics maintenance and programming would be created, there could be a displacement of human assemblers. Companies would need to consider strategies for reskilling or redeploying their existing workforce.

Addressing these challenges will require a phased approach, pilot programs, and ongoing research and development. The transition to robotic furniture assembly will likely be an evolutionary process rather than an overnight revolution.

The Future Workspace: Humans and Robots Collaborating

The narrative of robots replacing humans is often oversimplified. In the context of furniture assembly, a more likely scenario is one of collaboration, where humans and robots work together to achieve optimal outcomes. This symbiotic relationship aims to leverage the strengths of both.

The “Cobot” Advantage

Collaborative robots, or cobots, are designed to work safely alongside humans. They can handle the heavy lifting, the repetitive motions, and the precise fastening, while humans can focus on more nuanced tasks, quality checks, and problem-solving. Imagine a cobot handing perfectly sorted components to a human assembler, who then places them into their final position with a practiced touch.

Shifting Skill Sets

The introduction of robots will necessitate a shift in the skillset of the workforce. Instead of purely manual labor, there will be a greater demand for individuals with expertise in:

- Robotics operation and maintenance: Technicians who can program, monitor, and repair robotic systems.

- Quality assurance and control: Individuals who can oversee the automated processes and ensure product quality.

- Logistics and workflow optimization: Professionals who can integrate robotic systems into the broader supply chain.

- Customer support for automated services: Individuals who can assist customers with questions or issues related to robotic assembly.

Enhanced Productivity and Innovation

The combined efforts of humans and robots can lead to unprecedented levels of productivity. Robots can work continuously, reducing downtime and increasing throughput. Humans can then apply their creativity and critical thinking to innovate new designs, improve assembly processes, and address unforeseen challenges. This collaborative environment can become a fertile ground for new ideas and advancements.

A New Definition of “DIY”

The concept of “Do It Yourself” might evolve. While the traditional hands-on assembly may diminish for some, a new form of DIY could emerge where consumers interact with or oversee robotic assistance, still retaining a sense of involvement and control, albeit in a different capacity.

The future workspace in furniture assembly is not likely to be a sterile environment populated solely by machines. Instead, it will be a dynamic ecosystem where human ingenuity and robotic efficiency converge, creating a more streamlined, precise, and potentially more accessible assembly experience.

Conclusion: A More Assembled Future?

The journey towards robotic furniture assembly is gathering momentum, driven by technological advancements and the ongoing pursuit of efficiency and enhanced customer experience. The traditional model of IKEA assembly, while successful, has inherent limitations, and robotics offers a compelling solution to many of these.

The potential applications range from in-store robotic assistance to futuristic at-home services, each with its own set of benefits and challenges. Increased efficiency, improved quality, reduced physical strain, and greater accessibility are all attractive prospects. However, the significant initial investment, the complexity of designs, and the need for skilled human oversight are hurdles that must be addressed.

The future of furniture assembly is unlikely to be a wholesale replacement of humans by robots. Instead, it points towards a collaborative model where humans and robots work in tandem. This partnership can leverage the precision and endurance of machines with the creativity, adaptability, and problem-solving skills of humans.

For companies like IKEA, embracing robotic assembly represents a strategic evolution. It’s about streamlining operations, reducing costs, and ultimately, delivering a better product and a more satisfying customer experience. While the ubiquitous Allen key might not disappear overnight, the landscape of furniture assembly is undeniably shifting. The question isn’t if robotics will play a role, but rather how deeply and how quickly it will reshape the way we bring our furniture to life. The ultimate impact will be seen in how seamlessly and efficiently flat-pack furniture, once a testament to user assembly, becomes a testament to intelligent automation.

FAQs

What is robotic furniture assembly?

Robotic furniture assembly refers to the use of automated robots and machinery to put together furniture pieces, typically involving tasks such as aligning parts, fastening screws, and ensuring structural integrity without human intervention.

How could robotic assembly impact IKEA’s production process?

Robotic assembly could streamline IKEA’s production by increasing efficiency, reducing assembly time, minimizing human error, and potentially lowering labor costs, leading to faster product availability and consistent quality.

Are there any current examples of robotic furniture assembly in use?

Yes, some companies and research institutions have developed robotic systems capable of assembling flat-pack furniture, though widespread commercial adoption is still in early stages. IKEA has also explored automation technologies to enhance its manufacturing and logistics.

What challenges exist for implementing robotic furniture assembly at IKEA?

Challenges include the complexity and variability of furniture designs, the need for adaptable robots that can handle different components, high initial investment costs, and ensuring safety and reliability in the assembly process.

Will robotic assembly replace human workers at IKEA?

While robotic assembly may reduce the need for manual labor in certain tasks, it is more likely to complement human workers by handling repetitive or hazardous tasks, allowing employees to focus on quality control, customization, and customer service.