Industrial automation has long been a cornerstone of manufacturing, driving efficiency and precision. The integration of robotic systems, from articulated arms to automated guided vehicles, has redefined production lines. Presently, the frontier of factory automation is expanding to include humanoid robots – machines designed to mimic human form and, in theory, human dexterity and adaptability. This shift represents a potential paradigm change, moving beyond specialized, fixed-function robots to general-purpose machines capable of a broader range of tasks. This article will examine two prominent players in this evolving field: Tesla’s Optimus and Boston Dynamics’ continuing work, with a focus on their applications and implications within factory environments.

The rationale behind deploying humanoid robots in factories is multi-faceted. Traditional industrial robots excel at repetitive, high-volume tasks within structured environments. However, tasks requiring fine motor skills, adaptability to varied object geometries, or interaction with an environment designed for human workers often remain manual. Humanoid robots, by their very design, are presented as a potential solution to these challenges.

Addressing Labor Shortages and Demanding Tasks

Many industrialized nations face demographic shifts leading to labor shortages in manufacturing. Furthermore, certain factory tasks are ergonomically challenging, hazardous, or require prolonged standing or repetitive motions, contributing to worker fatigue and injury. Humanoid robots are posited as a means to fill these gaps, undertaking physically demanding or undesirable jobs, thereby improving working conditions for human employees and maintaining production output.

Leveraging Existing Infrastructure

A significant advantage of humanoid robots is their theoretical ability to operate within existing human-centric factory layouts. This contrasts with traditional industrial robots, which often necessitate extensive re-engineering of workspaces, safety enclosures, and tooling. A humanoid form factor, with its bipedal locomotion and human-like manipulators, suggests a reduced need for costly and time-consuming infrastructure modifications, offering a more plug-and-play solution in certain scenarios.

Enhancing Flexibility and Adaptability

Factories are dynamic entities. Production lines change, product designs evolve, and demand fluctuates. Current industrial robots, while precise, are often specialized and require significant reprogramming and re-tooling for new tasks. Humanoid robots, with their potential for general-purpose manipulation and learned behaviors, aim to offer greater flexibility. Imagine a single robot that can assemble a component one day and pack boxes the next, adapting to diverse tasks with minimal human intervention.

In the ongoing debate about the future of automation in manufacturing, a related article that explores the implications of advanced technologies is available at this link: Free SEO Tools for Beginners 2023. While the focus of the article is on digital marketing tools, it highlights the importance of integrating innovative technologies, such as humanoid robots like Tesla’s Optimus and Boston Dynamics’ creations, into various industries. The insights provided can help businesses understand how to leverage these advancements not only in manufacturing but also in enhancing their online presence and efficiency.

Tesla Optimus: The Manufacturing Innovator’s Approach

Tesla, known for its electric vehicles and a bold approach to manufacturing automation, introduced its humanoid robot project, Optimus. The initial presentation emphasized a vision where these robots would perform tasks deemed “boring or dangerous” for humans, starting within Tesla’s own factories.

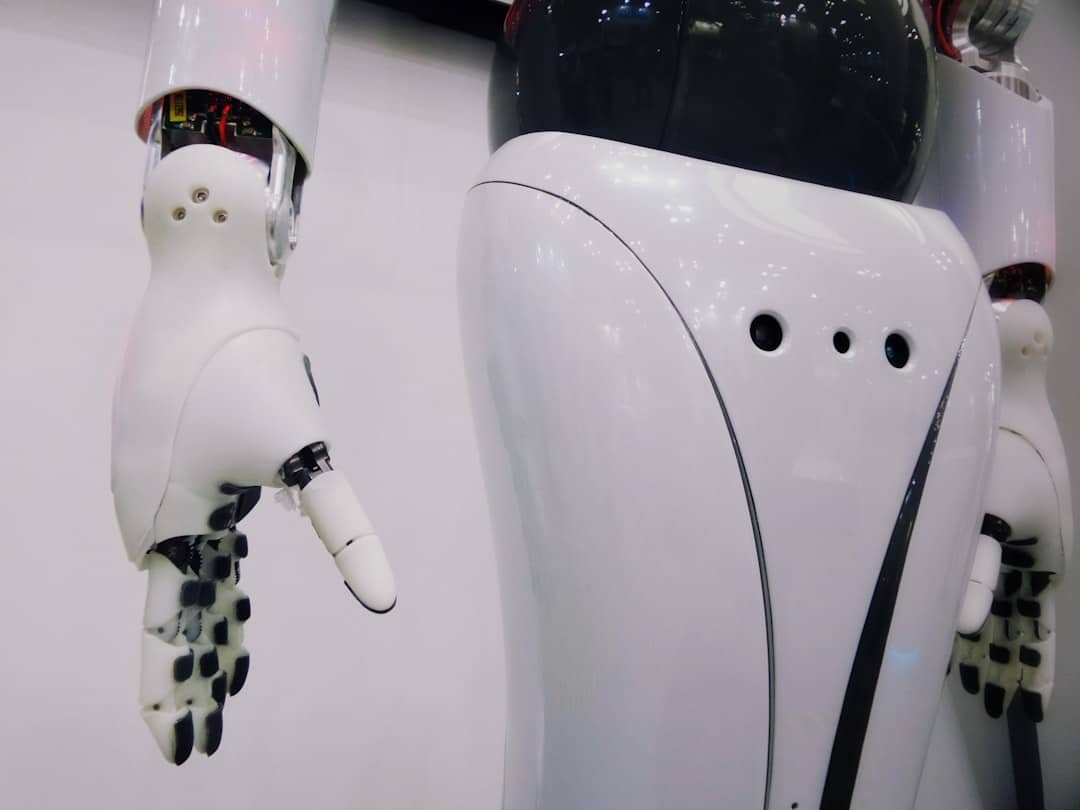

Design Principles and Iterations

Optimus’s design reflects a focus on simplicity and scalability. Early prototypes showcased a form factor roughly equivalent to a human, with two arms and two legs, designed to mimic human movements. The iterative development has focused on improving dexterity, locomotion, and autonomy. Tesla’s approach aligns with its broader manufacturing philosophy: rapid prototyping, vertical integration, and a drive toward high-volume production. The intention appears to be creating a cost-effective, mass-producible humanoid robot, akin to their vehicle production model.

Intended Factory Applications at Tesla

Within Tesla’s own Gigafactories, Optimus is envisioned as a multi-purpose worker. Initial demonstrations and statements suggest roles in material handling, such as moving parts, loading and unloading equipment, and performing basic assembly tasks. The ambition is to integrate Optimus into the assembly process, potentially performing a range of tasks that currently require human operators. This goes beyond simple pick-and-place, aiming for more complex manipulation and interaction with the factory environment.

Leveraging AI and Machine Learning

A core tenet of Optimus’s development is the integration of advanced artificial intelligence and machine learning. Tesla utilizes its expertise in autonomous driving, particularly in computer vision and real-world AI training, to develop Optimus’s perceptive and decision-making capabilities. The robots are intended to learn from demonstrations, adapt to changing conditions, and operate with increasing autonomy. This approach seeks to move beyond pre-programmed movements towards truly adaptive and intelligent robotic behavior within the factory setting.

Boston Dynamics: The Robotics Pioneer’s Perspective

Boston Dynamics, a long-standing leader in advanced robotics, has developed several highly capable robots, including quadrupedal robots like Spot and humanoid robots like Atlas. While Atlas is primarily a research platform for cutting-edge mobility and manipulation, Boston Dynamics’ experience provides valuable insights into the complexities of humanoid robotics.

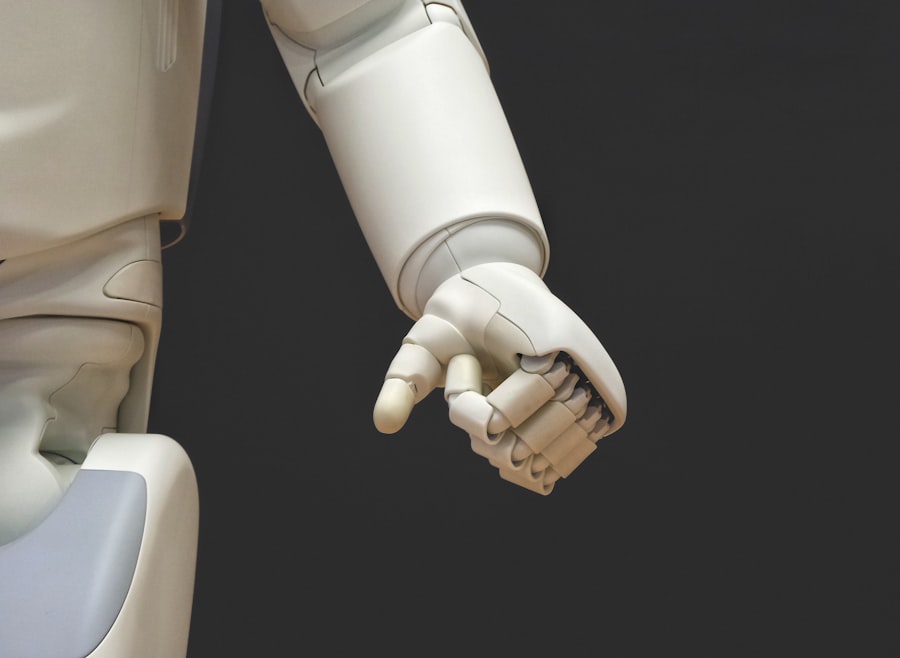

Atlas: A Research and Development Platform

Atlas is renowned for its dynamic balance, high-fidelity manipulation, and sophisticated motion capabilities. It can navigate complex terrains, perform parkour, and execute precise movements. However, Atlas is fundamentally a research platform. Its hydraulic actuation system provides immense power and agility but comes with complexities in terms of cost, maintenance, and energy consumption. The purpose of Atlas is to push the boundaries of what humanoid robots can achieve, rather than direct commercial deployment in factories in its current iteration.

Focus on Dynamic Mobility and Manipulation

Boston Dynamics emphasizes dynamic mobility and advanced manipulation. Their robots are designed to interact with unstructured and challenging environments. This expertise translates to the development of sophisticated control algorithms that enable robots to maintain balance, adapt to unexpected disturbances, and perform complex motor tasks. While Atlas itself may not walk onto a factory floor tomorrow, the fundamental research undertaken with it informs future generations of more production-ready robots.

Potential Spinoffs and Commercialization Strategy

While Atlas is a research platform, Boston Dynamics’ commercial strategy often involves leveraging the underlying technologies developed for its advanced robots into more practical applications. For example, the locomotion and perception systems developed for its larger robots could inform the design of smaller, more factory-appropriate humanoid or non-humanoid systems. The company’s acquisition by Hyundai signifies a potential pivot towards more practical industrial applications for elements of its robotics expertise, though direct humanoid factory deployment of Atlas is not its primary focus.

Comparative Analysis: Optimus vs. Boston Dynamics’ Approach

Comparing Optimus directly to Atlas is akin to comparing a concept car intended for mass production to a Formula 1 race car designed for ultimate performance and research. While both are vehicles, their immediate objectives and design philosophies diverge.

Design Philosophy and Actuation Systems

Optimus is designed for mass production and, presumably, aims for a more cost-effective electric actuation system. This prioritizes scalability and everyday feasibility. Atlas, in contrast, uses hydraulics, which offers unparalleled power and agility for research purposes but is less suited for mass market manufacturing dueability and cost. This fundamental difference in design choice reflects their respective goals: commercial application versus advanced research.

Autonomy and Learning Paradigms

Tesla’s Optimus heavily relies on neural networks and deep learning, leveraging the company’s significant investment in AI for autonomous driving. This “data-driven” approach aims for robots to learn from real-world interactions and simulation. Boston Dynamics, while also employing AI, often emphasizes model-predictive control and real-time adjustment, building on decades of robotics research into dynamic systems. Both seek autonomy, but their pathways to achieving it differ, much like two mountaineers might choose different routes up the same peak.

Readiness for Factory Integration

Optimus is explicitly being developed for factory integration, with Tesla’s own facilities serving as a living laboratory. The company’s vertical integration provides an immediate testing ground and a direct need. Boston Dynamics’ Atlas, while demonstrating impressive capabilities relevant to factory environments (like navigating obstacles or manipulating tools), is not being developed with immediate factory deployment as its primary objective. Its contributions are more foundational, pushing the boundaries of what is possible, which may eventually lead to commercial factory robots.

In the ongoing evolution of automation, the competition between Tesla’s Optimus and Boston Dynamics’ robots is a fascinating topic that highlights the advancements in humanoid robotics for factory settings. As companies strive to enhance efficiency and productivity, understanding the capabilities and applications of these robots becomes essential. For a deeper dive into how enterprise resource planning can integrate with such technologies, you can explore this insightful article on ERP solutions. This resource provides valuable information on optimizing operations in a rapidly changing technological landscape.

Challenges and Future Outlook for Humanoid Robots in Factories

| Feature / Metric | Tesla Optimus | Boston Dynamics Atlas |

|---|---|---|

| Height | 5 ft 8 in (173 cm) | 5 ft 9 in (175 cm) |

| Weight | 125 lbs (57 kg) | 180 lbs (82 kg) |

| Payload Capacity | Up to 45 lbs (20 kg) | Up to 55 lbs (25 kg) |

| Degrees of Freedom | ~40 | 28 |

| Mobility | Bipedal walking, basic navigation | Bipedal walking, running, jumping, parkour |

| Power Source | Battery (estimated multi-hour operation) | Battery (approx. 1 hour operation) |

| Primary Use Case | Factory automation, repetitive tasks | Research, complex terrain navigation, dynamic tasks |

| Control System | AI-driven with Tesla Dojo integration | Advanced control algorithms with sensor fusion |

| Release Status | Prototype / Early development | Advanced prototype / Demonstration units |

| Cost (approximate) | Not publicly disclosed | Not publicly disclosed |

The path to widespread humanoid robot deployment in factories is not without significant hurdles. These machines are complex systems at the intersection of mechanical engineering, advanced AI, and ethical considerations.

Technical Hurdles in Dexterity and Robustness

Achieving human-level dexterity – the ability to manipulate a wide variety of tools and objects with precision and force control – remains a significant challenge. Robustness, the ability to operate reliably in harsh industrial environments without frequent maintenance or failure, is also paramount. Factories are often dusty, noisy, and contain varying temperatures and vibrations, presenting a formidable test for delicate robotic systems.

Cost-Effectiveness and Return on Investment

For widespread adoption, humanoid robots must demonstrate a clear return on investment. The initial capital expenditure for these advanced machines is likely to be substantial. Their operational costs, including energy consumption, maintenance, and potential downtime, must be competitive with human labor or specialized industrial robots. The economic equation must balance the robot’s capabilities against its total cost of ownership.

Safety and Human-Robot Collaboration

Integrating humanoid robots into environments shared with human workers necessitates stringent safety protocols. The potential for accidents due to complex, general-purpose robots requires robust collision avoidance systems, fail-safes, and intuitive human-robot interaction interfaces. The development of safe and effective human-robot collaboration paradigms, where robots augment rather than replace human workers in every instance, will be critical.

Conclusion

The advent of humanoid robots like Tesla’s Optimus and the capabilities showcased by Boston Dynamics’ Atlas platforms represent a significant horizon in industrial automation. Optimus, with its focus on mass production and direct factory application within Tesla, aims to be a practical, scalable solution for labor-intensive tasks. Boston Dynamics, through its high-performance research platforms, continues to push the fundamental boundaries of humanoid mobility and manipulation, laying groundwork for future sophisticated robotic systems.

Factories are dynamic environments, demanding machines that are not only precise but also adaptable. Humanoid robots offer the promise of this adaptability, effectively functioning as a general-purpose tool within an infrastructure designed for humans. However, the journey from impressive demonstrations to widespread, reliable, and cost-effective deployment is fraught with engineering, economic, and safety challenges. As you, the reader, consider the future of factory automation, understand that these robots are not merely curiosities; they are complex experiments in reshaping the very fabric of industrial production, poised to redefine the relationship between human labor and intelligent machines. The factory of tomorrow may very well be a stage where humans and humanoids collaborate, each playing to their strengths, in a symphony of engineered efficiency.

FAQs

What are humanoid robots used for in factories?

Humanoid robots in factories are designed to perform tasks that typically require human-like dexterity and mobility. They can handle repetitive, dangerous, or precise operations such as assembly, inspection, material handling, and quality control, improving efficiency and safety in manufacturing environments.

What is Tesla Optimus?

Tesla Optimus is a humanoid robot developed by Tesla, intended to assist with labor-intensive tasks in factories and other settings. It features a human-like form with advanced sensors and AI capabilities, aiming to automate routine work and reduce the need for human labor in repetitive or hazardous jobs.

How does Boston Dynamics’ humanoid robot differ from Tesla Optimus?

Boston Dynamics’ humanoid robots, such as Atlas, are known for their advanced mobility, balance, and agility, capable of navigating complex terrains and performing dynamic movements like running and jumping. Tesla Optimus focuses more on practical factory tasks with an emphasis on integration with Tesla’s AI systems, whereas Boston Dynamics emphasizes physical capabilities and robotics research.

Are humanoid robots currently widely used in factories?

While humanoid robots are being developed and tested, they are not yet widely deployed in factories. Most current industrial automation relies on specialized robotic arms and machines. Humanoid robots are still in the research and early implementation stages, with companies like Tesla and Boston Dynamics working to make them more practical and cost-effective for industrial use.

What are the main challenges facing humanoid robots in factory settings?

Key challenges include ensuring safety around human workers, achieving reliable and precise manipulation of diverse objects, maintaining balance and mobility in complex environments, and developing AI systems capable of adapting to varied tasks. Additionally, cost and energy efficiency remain significant hurdles for widespread adoption.