The mining industry has long been characterized by its labor-intensive processes and hazardous working conditions. However, the advent of robotics has begun to transform this sector, introducing innovative technologies that enhance efficiency, safety, and sustainability. Robotics in mining encompasses a wide range of applications, from autonomous vehicles that transport materials to drones that conduct aerial surveys.

These advancements not only streamline operations but also address some of the industry’s most pressing challenges, such as worker safety and environmental degradation. As the demand for minerals and resources continues to rise, the integration of robotics into mining operations is becoming increasingly essential. The global push for sustainable practices has prompted mining companies to seek solutions that minimize their ecological footprint while maximizing output.

Robotics offers a pathway to achieve these goals, enabling companies to operate more effectively in remote and challenging environments. By leveraging automation and advanced technologies, the mining sector is poised to undergo a significant transformation that could redefine its future.

Key Takeaways

- Robotics in mining involves the use of automated machines and systems to perform various tasks in the mining industry, such as drilling, blasting, and hauling.

- Precision tools, such as drones and autonomous vehicles, are being used to improve the accuracy and efficiency of mining operations, leading to more sustainable practices.

- Robotics in mining operations offer advantages such as increased productivity, reduced downtime, and improved worker safety.

- The environmental impact of robotics in mining includes reduced emissions, minimized waste, and better land reclamation practices.

- Robotics in mining contribute to improved safety by reducing the exposure of workers to hazardous conditions and minimizing the risk of accidents.

- The use of robotics in mining leads to cost efficiency and productivity gains through reduced labor costs, optimized resource utilization, and faster operation cycles.

- Future trends in robotics for sustainable mining include the development of more advanced autonomous systems, increased use of artificial intelligence, and the integration of renewable energy sources.

- In conclusion, robotics play a crucial role in shaping the future of mining by promoting sustainability, safety, and efficiency in mining operations.

Precision Tools for Sustainable Mining

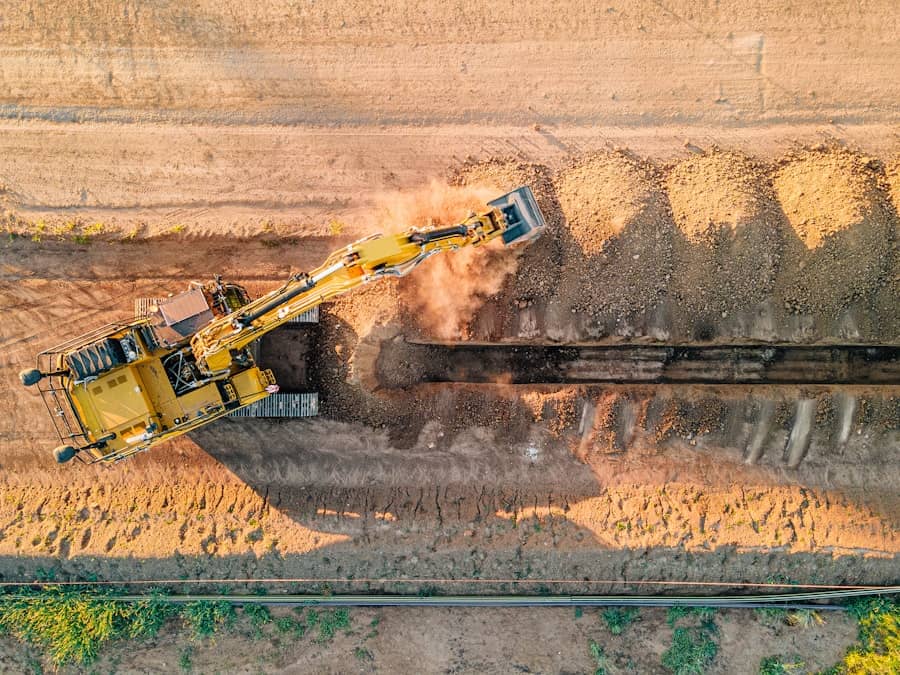

Precision tools powered by robotics are revolutionizing the way mining operations are conducted. These tools include automated drilling systems, robotic arms for material handling, and advanced sensors that monitor geological conditions in real-time. For instance, automated drilling rigs can operate with remarkable accuracy, reducing the amount of waste generated during the extraction process.

By precisely targeting ore deposits, these systems minimize the environmental impact associated with traditional mining methods, which often involve extensive land disruption. Moreover, robotic technologies are being employed to enhance the efficiency of mineral processing. Automated sorting systems utilize machine learning algorithms to identify and separate valuable minerals from waste materials with high precision.

This not only increases recovery rates but also reduces the energy consumption associated with processing low-grade ores. The integration of these precision tools into mining operations exemplifies how robotics can contribute to more sustainable practices by optimizing resource utilization and minimizing waste.

Advantages of Robotics in Mining Operations

The advantages of incorporating robotics into mining operations are manifold. One of the most significant benefits is the enhancement of operational efficiency. Automated systems can work continuously without the need for breaks, leading to increased productivity levels.

For example, autonomous haul trucks can transport materials around the clock, significantly reducing cycle times and improving overall throughput. This level of efficiency is particularly crucial in an industry where time is often equated with money. In addition to efficiency gains, robotics also facilitates improved data collection and analysis.

Advanced sensors and monitoring systems can gather vast amounts of data regarding equipment performance, geological conditions, and environmental factors. This data can be analyzed in real-time to inform decision-making processes, allowing operators to respond swiftly to changing conditions on-site. The ability to harness data effectively not only enhances operational performance but also contributes to better planning and resource management.

Environmental Impact of Robotics in Mining

The environmental impact of traditional mining practices has been a longstanding concern, prompting calls for more sustainable approaches. Robotics offers a promising solution by minimizing the ecological footprint of mining operations. For instance, remote-controlled drones are increasingly used for environmental monitoring and site assessments.

These drones can survey large areas quickly and efficiently, providing valuable insights into land use changes, vegetation health, and potential contamination issues without disturbing the ecosystem. Furthermore, robotic technologies can facilitate more responsible waste management practices. Automated systems can be designed to sort and process waste materials more effectively, ensuring that recyclable materials are recovered and reducing the volume of waste sent to landfills.

By implementing these technologies, mining companies can significantly reduce their environmental impact while adhering to stricter regulations aimed at protecting natural resources.

Safety Benefits of Robotics in Mining

Safety is a paramount concern in the mining industry, where workers are often exposed to hazardous conditions such as toxic gases, cave-ins, and heavy machinery accidents. The introduction of robotics has the potential to significantly enhance safety protocols by reducing human exposure to dangerous environments. For example, robotic exploration vehicles can be deployed in underground mines to assess conditions before human workers enter.

These vehicles can navigate treacherous terrain and gather critical data without putting lives at risk. Additionally, automated systems can take over repetitive or physically demanding tasks that pose a risk to workers’ health and safety. Tasks such as heavy lifting or operating machinery in confined spaces can be performed by robots, thereby minimizing the likelihood of injuries related to fatigue or accidents.

The implementation of robotics not only protects workers but also fosters a culture of safety within mining operations by prioritizing human well-being.

Cost Efficiency and Productivity Gains with Robotics

Reduced Maintenance Costs

For instance, automated equipment typically requires less maintenance than traditional machinery due to its precision engineering and reduced wear and tear from human operation.

Productivity Gains and Profitability

Moreover, the productivity gains associated with robotics can lead to increased profitability for mining companies. By optimizing processes and reducing downtime through automation, companies can achieve higher output levels without proportionately increasing labor costs.

Operational Efficiency and Survival

This is particularly relevant in an industry where profit margins can be thin and operational efficiency is critical for survival. As companies continue to adopt robotic technologies, they are likely to see a positive impact on their bottom line, with potential for

Long-Term Financial Benefits

further financial benefits as the technology continues to evolve and improve.

Future Trends in Robotics for Sustainable Mining

Looking ahead, several trends are emerging in the field of robotics that promise to further enhance sustainability in mining operations. One notable trend is the development of collaborative robots, or cobots, which are designed to work alongside human operators rather than replace them entirely. These robots can assist workers in various tasks, improving efficiency while maintaining a human touch in operations that require decision-making or creativity.

Another trend is the increasing use of artificial intelligence (AI) in robotic systems for predictive maintenance and operational optimization. By analyzing data collected from sensors embedded in equipment, AI algorithms can predict when machinery is likely to fail or require maintenance. This proactive approach not only reduces downtime but also extends the lifespan of equipment, contributing to more sustainable practices by minimizing resource consumption.

Additionally, advancements in battery technology are paving the way for more sustainable robotic solutions in mining. Electric-powered autonomous vehicles are becoming more prevalent as battery efficiency improves, reducing reliance on fossil fuels and lowering greenhouse gas emissions associated with mining operations. As these trends continue to evolve, they will play a crucial role in shaping a more sustainable future for the mining industry.

The Role of Robotics in Shaping the Future of Mining

The integration of robotics into mining operations represents a paradigm shift that addresses some of the industry’s most pressing challenges while promoting sustainability and safety. As precision tools become more sophisticated and AI-driven technologies advance, the potential for robotics to revolutionize mining practices will only grow stronger. The benefits—ranging from enhanced operational efficiency and cost savings to improved safety measures—underscore the importance of embracing these innovations.

In an era where environmental concerns are paramount and resource demands are ever-increasing, robotics offers a viable pathway toward a more sustainable future for mining. By leveraging automation and advanced technologies, the industry can not only meet its production goals but also do so responsibly and ethically. As we look ahead, it is clear that robotics will play an integral role in shaping the future landscape of mining, ensuring that it evolves into a sector that prioritizes both productivity and sustainability.

A related article to How Robotics Supports Sustainable Mining Practices with Precision Tools is “Discover the Best AI Video Generator Software Today” which explores the advancements in artificial intelligence technology and its applications in video creation. This article highlights the importance of utilizing cutting-edge tools and software to enhance productivity and efficiency in various industries, including mining. To learn more about the latest AI video generator software, check out the article here.

FAQs

What is sustainable mining?

Sustainable mining refers to the responsible extraction of minerals and resources while minimizing environmental impact and promoting social and economic benefits for local communities.

How can robotics support sustainable mining practices?

Robotics can support sustainable mining practices by automating processes, reducing the need for human labor in hazardous environments, and improving precision and efficiency in mining operations.

What are precision tools in the context of mining?

Precision tools in mining refer to advanced equipment and technologies that enable accurate and controlled extraction, processing, and transportation of minerals, leading to reduced waste and environmental impact.

What are the environmental benefits of using robotics and precision tools in mining?

Using robotics and precision tools in mining can help minimize the disturbance of ecosystems, reduce air and water pollution, and decrease the consumption of natural resources, contributing to overall environmental sustainability.

How do robotics and precision tools contribute to the safety of mining operations?

By automating dangerous tasks, monitoring hazardous conditions, and improving accuracy and control, robotics and precision tools can enhance the safety of mining operations and reduce the risk of accidents and injuries for workers.