The advent of robotics in manufacturing has marked a transformative era in industrial processes, revolutionizing how products are designed, produced, and delivered. Robotics, defined as the branch of technology that deals with the design, construction, operation, and application of robots, has become an integral part of modern manufacturing systems. The integration of robotic systems into manufacturing environments has not only enhanced efficiency but has also redefined the capabilities of production lines.

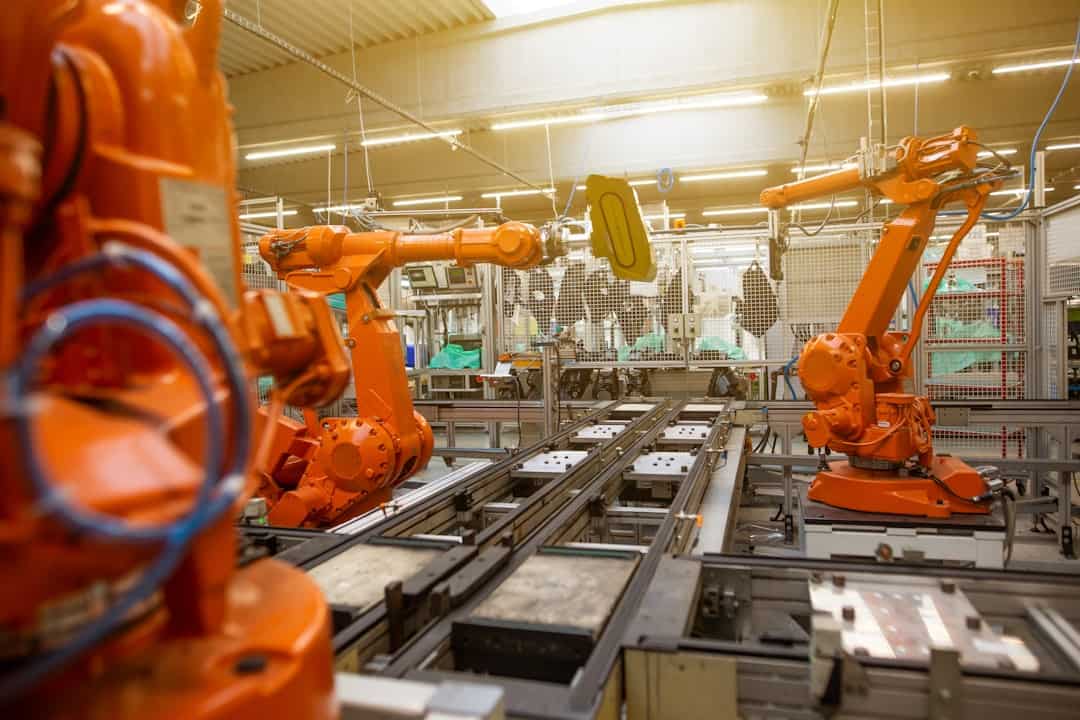

As industries strive for higher productivity and lower operational costs, the adoption of robotics has emerged as a strategic solution to meet these demands. From automotive assembly lines to electronics manufacturing, robots are increasingly taking on roles that were traditionally performed by human workers, leading to significant changes in the landscape of production. The evolution of robotics in manufacturing can be traced back to the mid-20th century when the first industrial robots were introduced.

These early machines were primarily used for repetitive tasks such as welding and painting, but advancements in technology have expanded their applications dramatically. Today’s robots are equipped with sophisticated sensors, artificial intelligence, and machine learning capabilities, allowing them to perform complex tasks with precision and adaptability. This evolution has not only improved the quality of products but has also enabled manufacturers to respond more swiftly to market demands.

As we delve deeper into the role of robotics in manufacturing, it becomes evident that these machines are not merely tools; they are pivotal players in the quest for operational excellence.

Key Takeaways

- Robotics in manufacturing has revolutionized the way products are made, increasing efficiency and precision.

- Robotics streamlines production processes by automating repetitive tasks, reducing errors, and increasing productivity.

- Advantages of robotics in manufacturing include improved quality, reduced costs, increased safety, and the ability to handle complex tasks.

- The impact of robotics on labor and employment is a topic of concern, as it can lead to job displacement and require retraining for new roles.

- Challenges and limitations of implementing robotics in manufacturing include high initial costs, technical complexity, and the need for skilled personnel to operate and maintain the systems.

The Role of Robotics in Streamlining Production Processes

Robotics plays a crucial role in streamlining production processes by automating tasks that are often labor-intensive and time-consuming. By integrating robotic systems into manufacturing workflows, companies can achieve a level of efficiency that is difficult to attain through human labor alone. Robots can operate continuously without fatigue, allowing for extended production runs that maximize output.

This capability is particularly beneficial in industries where demand fluctuates rapidly, as robots can be programmed to adapt to changing production requirements with minimal downtime. Furthermore, the precision of robotic systems reduces the likelihood of errors, leading to higher quality products and less waste. In addition to enhancing efficiency, robotics also facilitates better resource management within manufacturing environments.

Automated systems can monitor inventory levels in real-time, ensuring that materials are available when needed without overstocking. This not only optimizes the supply chain but also reduces costs associated with excess inventory. Moreover, robots can be integrated with advanced data analytics tools that provide insights into production performance, enabling manufacturers to identify bottlenecks and areas for improvement.

By leveraging robotics in this manner, companies can create a more agile and responsive production process that aligns closely with market demands.

Advantages of Robotics in Manufacturing

The advantages of incorporating robotics into manufacturing processes are manifold and extend beyond mere efficiency gains. One of the most significant benefits is the enhancement of workplace safety. Robots can take on hazardous tasks that pose risks to human workers, such as handling toxic materials or operating heavy machinery.

By delegating these dangerous jobs to robots, manufacturers can significantly reduce workplace accidents and injuries, fostering a safer environment for their employees. This shift not only protects workers but also minimizes potential liabilities for companies, ultimately contributing to a more sustainable business model. Another key advantage of robotics in manufacturing is the ability to achieve greater consistency and quality in production outputs.

Robots are designed to perform tasks with high precision and repeatability, which is essential in industries where even minor deviations can lead to significant quality issues. For instance, in the automotive sector, robotic arms are used for tasks such as welding and assembly, where precision is critical for ensuring that components fit together correctly. The consistent performance of robots helps maintain high standards of quality control, reducing the need for extensive inspections and rework.

As a result, manufacturers can enhance their reputation for quality while also improving customer satisfaction.

Impact of Robotics on Labor and Employment

The integration of robotics into manufacturing has sparked considerable debate regarding its impact on labor and employment. On one hand, the automation of tasks traditionally performed by humans raises concerns about job displacement and the potential loss of skilled labor positions. As robots take over repetitive and manual tasks, there is a fear that many workers may find themselves out of work or forced to transition into new roles that require different skill sets.

This shift necessitates a reevaluation of workforce training programs to ensure that employees are equipped with the skills needed to thrive in an increasingly automated environment. Conversely, while some jobs may be lost due to automation, new opportunities are also created as a result of robotics integration. The demand for skilled technicians who can program, maintain, and troubleshoot robotic systems is on the rise.

Additionally, as companies adopt more advanced technologies, there is a growing need for professionals who can analyze data generated by these systems and optimize production processes accordingly. This evolution highlights the importance of reskilling and upskilling initiatives within the workforce to prepare employees for the changing landscape of manufacturing jobs. Ultimately, while robotics may disrupt traditional employment patterns, it also presents opportunities for growth and innovation within the labor market.

Challenges and Limitations of Implementing Robotics in Manufacturing

Despite the numerous benefits associated with robotics in manufacturing, several challenges and limitations must be addressed for successful implementation. One significant hurdle is the high initial investment required for robotic systems. The cost of purchasing and installing advanced robotic equipment can be prohibitive for small and medium-sized enterprises (SMEs), which may lack the financial resources to make such investments.

Additionally, ongoing maintenance and operational costs can further strain budgets, making it essential for companies to conduct thorough cost-benefit analyses before committing to automation projects. Another challenge lies in the complexity of integrating robotic systems into existing manufacturing processes. Many facilities have legacy equipment and workflows that may not be compatible with new robotic technologies.

This incompatibility can lead to disruptions during implementation and may require significant modifications to current operations. Furthermore, there is often a steep learning curve associated with training employees to work alongside robots effectively. Companies must invest time and resources into developing training programs that equip their workforce with the necessary skills to collaborate with automated systems seamlessly.

Future Trends and Innovations in Robotics for Manufacturing

Collaborative Robots: Enhancing Human-Robot Interaction

As technology continues to advance at an unprecedented pace, the future of robotics in manufacturing is poised for exciting developments. One notable trend is the increasing use of collaborative robots, or cobots, which are designed to work alongside human operators rather than replacing them entirely. These robots are equipped with advanced sensors and safety features that allow them to operate safely in close proximity to humans.

Enhancing Productivity with Cobots

Cobots can assist workers with tasks such as assembly or material handling, enhancing productivity while maintaining a human touch in the manufacturing process. By working together, humans and cobots can achieve greater efficiency and accuracy, leading to improved product quality and reduced production costs.

The Integration of Artificial Intelligence in Robotics

Another emerging trend is the integration of artificial intelligence (AI) and machine learning into robotic systems. By leveraging AI algorithms, robots can learn from their experiences and adapt their behaviors based on real-time data inputs. This capability enables them to optimize their performance continuously and make decisions autonomously when faced with unexpected challenges on the production line.

Case Studies of Successful Integration of Robotics in Manufacturing

Numerous case studies illustrate the successful integration of robotics into manufacturing processes across various industries. One prominent example is Tesla’s use of robotics in its automotive production facilities. The company has implemented advanced robotic systems for tasks such as welding, painting, and assembly, significantly increasing production efficiency while maintaining high-quality standards.

By automating these processes, Tesla has been able to scale its operations rapidly and meet growing demand for electric vehicles while minimizing labor costs. Another noteworthy case is that of Fanuc Corporation, a leading manufacturer of industrial robots based in Japan. Fanuc has successfully integrated robotics into its own production lines by utilizing its own robotic technology for assembly and quality control processes.

This self-referential approach not only showcases the capabilities of its products but also allows Fanuc to maintain strict quality control over its manufacturing operations. The company’s commitment to automation has resulted in increased productivity and reduced lead times, setting a benchmark for other manufacturers looking to adopt similar strategies.

The Future of Manufacturing with Robotics

In conclusion, the future of manufacturing is undeniably intertwined with advancements in robotics technology. As industries continue to embrace automation as a means to enhance efficiency and productivity, it is essential to recognize both the opportunities and challenges that come with this transformation. While concerns about job displacement persist, it is crucial to focus on reskilling initiatives that prepare workers for new roles within an increasingly automated landscape.

The integration of robotics not only promises improved operational performance but also fosters innovation across various sectors. Looking ahead, we can anticipate further innovations in robotics that will redefine manufacturing processes even further. The rise of collaborative robots and AI-driven automation will enable manufacturers to create more flexible and responsive production environments capable of adapting to changing market demands swiftly.

As companies continue to explore the potential of robotics, it is clear that this technology will play a pivotal role in shaping the future of manufacturing—one characterized by enhanced efficiency, improved safety standards, and a renewed focus on quality and innovation.

In exploring the transformative impact of technology across various sectors, it’s fascinating to see how innovations extend beyond just manufacturing. For instance, the realm of sustainable energy is also experiencing significant advancements, driven by visionary entrepreneurs and technological breakthroughs. A related article that delves into this topic is “How One Founder Realized the Potential of Sustainable Energy,” which provides an insightful look into the journey of a founder who harnessed the power of sustainable technologies to make a substantial impact. You can read more about this inspiring story and its implications for the future of energy by visiting How One Founder Realized the Potential of Sustainable Energy. This article not only complements the discussion on robotics in manufacturing but also broadens the scope to include how similar technologies are revolutionizing other critical sectors.

FAQs

What is robotics in manufacturing?

Robotics in manufacturing refers to the use of automated machines and systems to perform tasks traditionally carried out by human workers in a factory or production setting. These robots are programmed to perform specific tasks such as assembly, welding, painting, packaging, and more.

How is robotics revolutionizing manufacturing?

Robotics is revolutionizing manufacturing by increasing efficiency, precision, and productivity in production processes. Robots can work 24/7 without breaks, leading to faster production cycles and reduced downtime. They also improve safety by handling hazardous tasks and repetitive motions, while also reducing the risk of human error.

What are the benefits of using robotics in manufacturing?

The benefits of using robotics in manufacturing include increased productivity, improved product quality, reduced labor costs, enhanced workplace safety, and the ability to handle complex tasks with precision. Additionally, robotics can help manufacturers stay competitive in the global market by streamlining production processes.

What are some examples of robotics in manufacturing?

Examples of robotics in manufacturing include robotic arms for assembly and welding, automated guided vehicles (AGVs) for material handling, robotic palletizers for packaging, and collaborative robots (cobots) that work alongside human workers. These robots are used in various industries such as automotive, electronics, food and beverage, and pharmaceuticals.

What are the challenges of implementing robotics in manufacturing?

Challenges of implementing robotics in manufacturing include the initial investment cost, the need for specialized training for programming and maintenance, and the potential displacement of human workers. Additionally, integrating robotics into existing production processes and ensuring compatibility with other equipment can be a challenge.