The furniture manufacturing industry has witnessed a significant transformation over the past few decades, largely driven by advancements in technology. Among these advancements, robotics has emerged as a pivotal force reshaping how furniture is designed, produced, and delivered. The integration of robotic systems into manufacturing processes has not only streamlined operations but has also introduced a level of precision and customization that was previously unattainable.

As consumer preferences shift towards personalized products, the demand for innovative solutions in furniture production has surged, prompting manufacturers to adopt robotic technologies to meet these evolving needs. The rise of robotics in furniture manufacturing can be traced back to the broader trends in automation across various industries. Initially, robots were primarily employed for repetitive tasks such as assembly and painting.

However, as technology advanced, their capabilities expanded to include more complex functions such as cutting, shaping, and even assembling intricate designs. This evolution has allowed manufacturers to produce a wider range of products with greater efficiency. For instance, companies like IKEA have begun to incorporate robotic systems in their production lines, enabling them to respond swiftly to market demands while maintaining high standards of quality and design.

Key Takeaways

- Robotics has revolutionized furniture manufacturing, leading to increased efficiency and precision in production.

- Using robotics in customized furniture production offers advantages such as faster production times and the ability to create complex designs.

- Robotics enhances efficiency and precision in furniture manufacturing by automating repetitive tasks and ensuring consistent quality.

- Robotics plays a crucial role in designing and creating customized furniture by enabling the production of unique and intricate designs.

- Integrating robotics with traditional craftsmanship in furniture production allows for the combination of modern technology with artisanal skills.

- Robotics has a significant impact on customized furniture design and innovation by enabling the creation of new and innovative designs.

- Overcoming challenges in implementing robotics in customized furniture manufacturing requires addressing issues such as cost, training, and integration with existing processes.

- The future of robotics in customized furniture production is promising, with continued advancements in technology leading to further improvements in efficiency and design capabilities.

Advantages of Using Robotics in Customized Furniture Production

One of the most significant advantages of utilizing robotics in customized furniture production is the ability to achieve a high degree of personalization without sacrificing efficiency. Traditional manufacturing methods often struggle to balance customization with production speed, leading to longer lead times and increased costs. In contrast, robotic systems can be programmed to execute a variety of tasks with minimal downtime, allowing manufacturers to produce bespoke pieces tailored to individual customer specifications quickly.

This flexibility not only enhances customer satisfaction but also opens new revenue streams for manufacturers who can offer unique designs that cater to niche markets. Moreover, robotics can significantly reduce human error in the production process. In furniture manufacturing, precision is paramount; even minor inaccuracies can lead to costly rework or product failures.

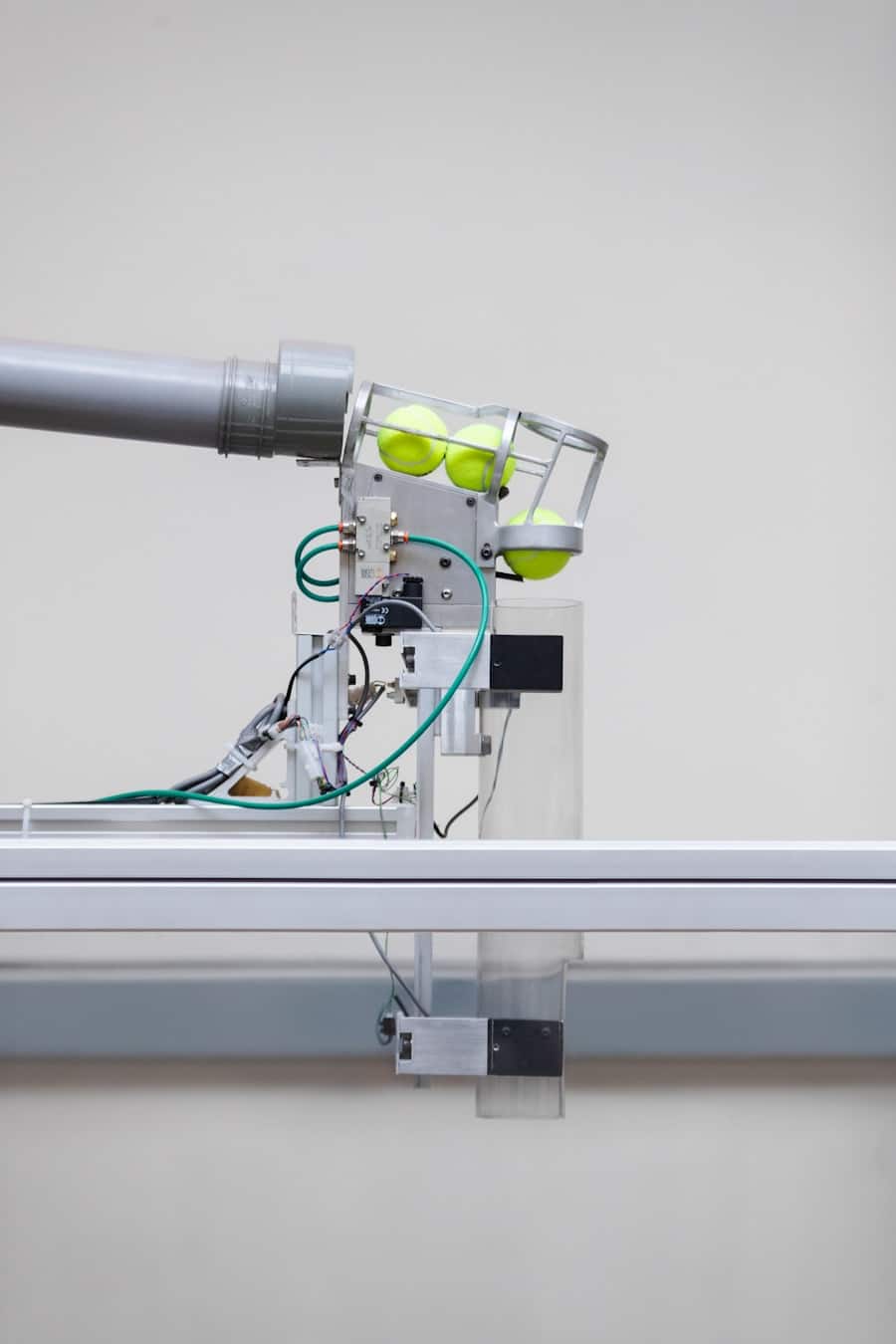

Robots equipped with advanced sensors and machine learning algorithms can perform tasks with remarkable accuracy, ensuring that each piece meets stringent quality standards. For example, a robotic arm can be programmed to cut wood or other materials with millimeter precision, reducing waste and ensuring that every component fits perfectly during assembly. This level of accuracy not only improves product quality but also enhances the overall efficiency of the manufacturing process.

How Robotics Enhances Efficiency and Precision in Furniture Manufacturing

The integration of robotics into furniture manufacturing processes has led to remarkable improvements in both efficiency and precision. Automated systems can operate continuously without the need for breaks, allowing for higher production rates compared to traditional labor-intensive methods. This continuous operation is particularly beneficial in high-demand periods when manufacturers need to ramp up production quickly to meet customer orders.

For instance, during peak seasons such as back-to-school or holiday sales, robotic systems can help manufacturers maintain output levels without compromising quality. In addition to increased output, robotics enhances precision through advanced technologies such as computer numerical control (CNC) machining. CNC machines utilize computer programming to control the movement of tools and machinery with extreme accuracy.

This technology allows for intricate designs and complex shapes that would be challenging or impossible to achieve manually. For example, a CNC router can carve detailed patterns into wood or composite materials, enabling designers to create unique textures and finishes that elevate the aesthetic appeal of furniture pieces. The combination of speed and precision provided by robotics not only streamlines production but also allows for greater creative freedom in design.

The Role of Robotics in Designing and Creating Customized Furniture

Robotics plays a crucial role not only in the manufacturing phase but also in the design process of customized furniture. Advanced software tools integrated with robotic systems enable designers to visualize and simulate their creations before they are physically produced.

For instance, a designer can use 3D modeling software to create a virtual representation of a piece of furniture and then utilize robotic systems to produce a prototype for testing. Furthermore, robotics facilitates collaboration between designers and manufacturers by providing real-time data on production capabilities and constraints. Designers can input their specifications into the system, which then analyzes the feasibility of producing the desired piece within given parameters such as material availability and cost constraints.

This collaborative approach ensures that the final product aligns with both aesthetic goals and practical manufacturing considerations. As a result, the integration of robotics into the design phase fosters innovation while maintaining a focus on manufacturability.

Integrating Robotics with Traditional Craftsmanship in Furniture Production

While robotics offers numerous advantages in efficiency and precision, it is essential to recognize the value of traditional craftsmanship in furniture production. Many consumers still appreciate the artistry and skill involved in handcrafted pieces. Therefore, integrating robotics with traditional craftsmanship presents an opportunity to combine the best of both worlds.

By leveraging robotic systems for repetitive or labor-intensive tasks while allowing skilled artisans to focus on intricate details and finishing touches, manufacturers can create high-quality products that appeal to a broader audience. For example, a furniture manufacturer might use robotic arms for tasks such as cutting and assembling components while employing skilled craftsmen for sanding, staining, and applying finishes. This hybrid approach not only enhances productivity but also preserves the artisanal qualities that many consumers seek in customized furniture.

Additionally, artisans can use robotic tools to assist them in their work, such as using CNC machines for precise cuts that would be time-consuming if done manually. This collaboration between technology and craftsmanship results in products that embody both innovation and tradition.

The Impact of Robotics on Customized Furniture Design and Innovation

The impact of robotics on customized furniture design extends beyond mere efficiency; it also fosters innovation by enabling designers to explore new materials and techniques that were previously impractical. With robotic systems capable of handling complex geometries and diverse materials, designers are free to experiment with unconventional shapes and structures that challenge traditional notions of furniture design. For instance, 3D printing technology combined with robotics allows for the creation of intricate lattice structures that are lightweight yet strong, opening up new possibilities for sustainable furniture solutions.

Moreover, robotics facilitates rapid iteration in the design process, allowing designers to test multiple concepts quickly without incurring significant costs or delays. This agility encourages a culture of experimentation where innovative ideas can be explored without fear of failure. As a result, manufacturers can stay ahead of market trends by continuously introducing fresh designs that resonate with consumers’ evolving tastes.

The synergy between robotics and design innovation ultimately leads to a more dynamic furniture market where creativity thrives alongside technological advancement.

Overcoming Challenges in Implementing Robotics in Customized Furniture Manufacturing

Despite the numerous benefits associated with integrating robotics into customized furniture manufacturing, several challenges must be addressed for successful implementation. One significant hurdle is the initial investment required for robotic systems and associated technologies. While the long-term savings from increased efficiency may justify this investment, smaller manufacturers may struggle to secure the necessary capital upfront.

To mitigate this challenge, industry stakeholders can explore financing options or government grants aimed at promoting automation within small businesses. Another challenge lies in workforce adaptation. As robotics take on more tasks traditionally performed by human workers, there may be concerns about job displacement within the industry.

To address this issue, manufacturers should prioritize workforce training programs that equip employees with the skills needed to work alongside robotic systems effectively. By fostering a culture of continuous learning and adaptation, companies can ensure that their workforce remains relevant in an increasingly automated landscape while also benefiting from the efficiencies that robotics provide.

The Future of Robotics in Customized Furniture Production

Looking ahead, the future of robotics in customized furniture production appears promising as technology continues to evolve at an unprecedented pace. Emerging trends such as artificial intelligence (AI) and machine learning are set to further enhance the capabilities of robotic systems, enabling them to learn from past experiences and optimize production processes autonomously. This evolution could lead to even greater efficiencies and innovations within the industry as robots become more adept at handling complex tasks.

Automated systems can optimize material usage, reduce waste, and facilitate recycling efforts by efficiently processing leftover materials into new products. As manufacturers increasingly prioritize sustainability alongside customization, robotics will be instrumental in achieving these goals while maintaining high standards of quality and design.

In conclusion, the integration of robotics into customized furniture manufacturing represents a transformative shift that enhances efficiency, precision, and innovation within the industry. By embracing this technological evolution while respecting traditional craftsmanship, manufacturers can create unique products that meet the diverse needs of modern consumers while paving the way for a sustainable future.

In a world where technology is constantly evolving, the article “The Best Tech Products 2023” highlights the latest innovations that are shaping our future. From cutting-edge laptops for kids to tablets with SIM card slots, these products are revolutionizing the way we live and work. Just like how robotics is powering customized furniture manufacturing, these tech products are pushing the boundaries of what is possible in the digital age. As we continue to embrace automation and artificial intelligence in various industries, it is crucial to stay informed about the latest advancements in technology.

FAQs

What is customized furniture manufacturing?

Customized furniture manufacturing refers to the process of creating furniture that is tailored to the specific needs and preferences of individual customers. This can include unique designs, sizes, materials, and finishes.

How is robotics used in customized furniture manufacturing?

Robotics is used in customized furniture manufacturing to automate various processes such as cutting, shaping, sanding, and assembling components. This helps to increase efficiency, precision, and consistency in the production of customized furniture.

What are the benefits of using robotics in customized furniture manufacturing?

Some of the benefits of using robotics in customized furniture manufacturing include increased production speed, improved quality control, reduced labor costs, and the ability to handle complex and intricate designs with greater accuracy.

How does robotics enable mass customization in furniture manufacturing?

Robotics enables mass customization in furniture manufacturing by allowing for the efficient production of unique and personalized furniture pieces at a scale that was previously not feasible. This is achieved through the use of advanced robotic systems that can adapt to different design specifications and produce customized furniture in a cost-effective manner.

What are some examples of robotics technologies used in customized furniture manufacturing?

Examples of robotics technologies used in customized furniture manufacturing include CNC (Computer Numerical Control) machines for precision cutting and shaping, robotic arms for automated assembly, and advanced software systems for design customization and production planning.