The integration of robotics into the recycling industry marks a significant evolution in how waste management is approached. As global waste generation continues to rise, driven by urbanization and consumerism, the need for efficient recycling processes has never been more pressing. Robotics offers innovative solutions that not only enhance operational efficiency but also address the complexities of sorting and processing diverse materials.

The application of robotic technology in recycling facilities is transforming traditional methods, enabling a more sustainable approach to waste management. Robots are increasingly being deployed to tackle the challenges associated with recycling, such as labor shortages, the need for precision in sorting, and the handling of hazardous materials. These machines are designed to work alongside human operators, augmenting their capabilities and allowing for a more streamlined workflow.

The advent of robotics in recycling is not merely a trend; it represents a fundamental shift in how materials are recovered and repurposed, paving the way for a circular economy where resources are reused rather than discarded.

Key Takeaways

- Robotics enhances recycling by automating sorting and material recovery processes.

- Automated systems increase efficiency and productivity in recycling facilities.

- Use of robots improves worker safety by handling hazardous materials.

- Integration of artificial intelligence enables more accurate sorting and contamination reduction.

- Future advancements promise further improvements in recycling operations and sustainability.

Automated Sorting Processes

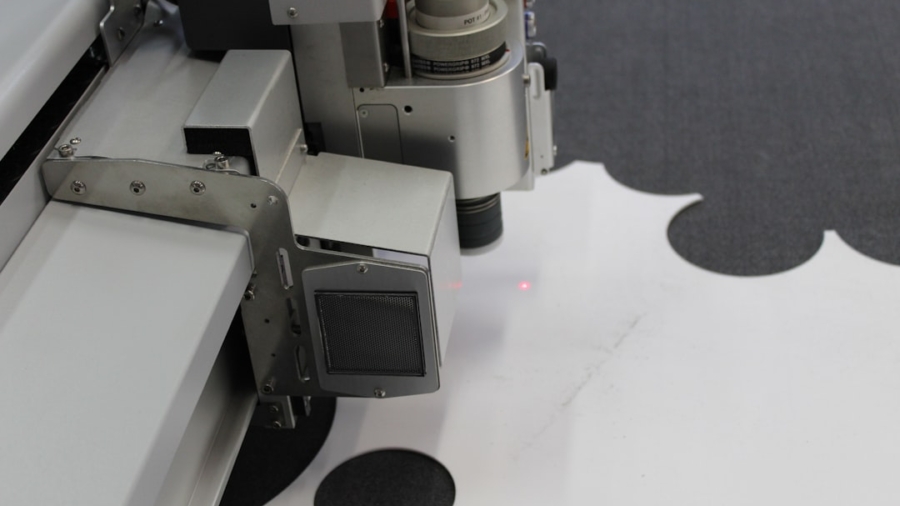

Automated sorting processes are at the forefront of robotic applications in recycling. Traditional sorting methods often rely on manual labor, which can be slow and prone to errors. In contrast, robotic systems utilize advanced sensors and machine learning algorithms to identify and separate materials with remarkable accuracy.

For instance, optical sensors can detect different types of plastics based on their color and composition, while artificial intelligence algorithms can learn from previous sorting tasks to improve future performance. One notable example of automated sorting is the use of robotic arms equipped with specialized grippers that can handle various materials, from glass to metals to plastics. These robots can operate at high speeds, significantly increasing the throughput of recycling facilities.

Companies like AMP Robotics have developed systems that not only sort materials but also provide real-time data analytics, allowing operators to monitor performance and make informed decisions about their recycling processes. This level of automation reduces the reliance on human labor for repetitive tasks, freeing workers to focus on more complex operations that require human judgment.

Increased Efficiency and Productivity

The implementation of robotics in recycling operations has led to substantial increases in efficiency and productivity. By automating sorting processes, facilities can process larger volumes of waste in shorter timeframes. For example, a robotic sorting system can sort thousands of items per hour, far surpassing the capabilities of manual sorting teams.

This enhanced efficiency translates into higher recovery rates for recyclable materials, which is crucial for meeting both environmental goals and economic targets. Moreover, robotics can operate continuously without the fatigue that human workers experience. This capability allows recycling facilities to maintain consistent output levels throughout the day and night, maximizing operational hours.

The integration of robotics also minimizes downtime associated with human breaks or shift changes, further contributing to productivity gains. As a result, recycling facilities equipped with robotic systems can achieve higher profitability while simultaneously reducing their environmental footprint by increasing the volume of materials diverted from landfills.

Improved Safety for Workers

The introduction of robotics into recycling operations has significant implications for worker safety. Recycling facilities often present hazardous working conditions due to the presence of sharp objects, toxic materials, and heavy machinery. By deploying robots to handle the most dangerous tasks—such as sorting through potentially harmful waste—facilities can mitigate risks associated with manual labor.

This shift not only protects workers from injury but also enhances overall workplace morale. Robots are designed to operate in environments that may be unsafe for humans, such as areas with high levels of dust or exposure to hazardous substances. For instance, robotic systems can be programmed to handle e-waste, which often contains toxic components like lead and mercury.

By automating these processes, facilities reduce the likelihood of accidents and health issues among employees. Furthermore, as robots take on more physically demanding tasks, workers can be retrained for roles that require critical thinking and problem-solving skills, fostering a safer and more skilled workforce.

Integration of Artificial Intelligence

Artificial intelligence (AI) plays a pivotal role in enhancing the capabilities of robotics within the recycling sector. AI algorithms enable robots to learn from their environment and adapt to varying conditions, improving their sorting accuracy over time. For example, machine learning models can analyze vast amounts of data from previous sorting operations to identify patterns and optimize performance.

This adaptability is crucial in recycling, where the composition of waste streams can change frequently. The integration of AI also allows for predictive maintenance of robotic systems. By monitoring performance metrics and identifying potential issues before they lead to breakdowns, facilities can minimize downtime and maintain operational efficiency.

Additionally, AI-driven analytics provide insights into material flows and recovery rates, enabling facility managers to make data-informed decisions that enhance overall productivity. As AI technology continues to evolve, its applications in recycling will likely expand, leading to even more sophisticated robotic systems capable of tackling complex sorting challenges.

Reduction of Contamination in Recycling Streams

One of the critical challenges in recycling is contamination within material streams, which can significantly hinder the quality and value of recovered materials.

For instance, robotic systems can utilize near-infrared spectroscopy to analyze materials at a molecular level, distinguishing between different types of plastics and detecting contaminants such as food residue or mixed materials. By effectively removing these contaminants during the sorting process, facilities can improve the purity of their recyclables, leading to higher-quality end products that are more desirable in the market. This reduction in contamination not only enhances operational efficiency but also contributes to a more sustainable recycling ecosystem by ensuring that more materials are successfully recycled rather than discarded.

Advancements in Material Recovery

The advancements in robotics have also led to significant improvements in material recovery rates within recycling operations. As robots become more adept at identifying and sorting various materials, facilities are able to recover a broader range of recyclables than ever before. For example, innovations in robotic technology have enabled the efficient recovery of complex materials such as multi-layer packaging or composite materials that were previously challenging to process.

Moreover, advancements in robotics have facilitated the recovery of valuable metals from electronic waste (e-waste), which is becoming an increasingly important area of focus due to the growing volume of discarded electronics. Robotic systems equipped with specialized tools can disassemble electronic devices and extract precious metals like gold and silver with minimal environmental impact. This capability not only enhances material recovery rates but also supports the circular economy by ensuring that valuable resources are reused rather than lost.

Future Outlook for Robotics in Recycling Operations

Looking ahead, the future of robotics in recycling operations appears promising as technology continues to advance at an unprecedented pace. The ongoing development of more sophisticated AI algorithms will likely lead to even greater improvements in sorting accuracy and efficiency. As robots become increasingly capable of handling diverse materials and adapting to changing waste streams, recycling facilities will be better equipped to meet the demands of a rapidly evolving industry.

Furthermore, as public awareness regarding sustainability grows, there will be increased pressure on recycling operations to enhance their performance and reduce environmental impact. Robotics will play a crucial role in meeting these expectations by enabling higher recovery rates and minimizing contamination levels. The collaboration between human workers and robotic systems will also evolve, fostering a new workforce dynamic where technology complements human skills rather than replacing them.

In conclusion, the integration of robotics into recycling operations is set to revolutionize the industry by enhancing efficiency, improving safety, reducing contamination, and increasing material recovery rates. As technology continues to advance, it will be essential for recycling facilities to embrace these innovations to remain competitive and contribute meaningfully to sustainability efforts worldwide. The future landscape of recycling will undoubtedly be shaped by the ongoing evolution of robotics and artificial intelligence, paving the way for a more sustainable approach to waste management.

In exploring the advancements in recycling operations through robotics, it’s interesting to note how technology is reshaping various sectors. For instance, the article on Hacker Noon discusses a range of topics across the tech sector, including innovations that can enhance efficiency in recycling processes. This intersection of robotics and technology not only improves operational efficiency but also contributes to more sustainable practices in waste management.

FAQs

What role do robots play in recycling operations?

Robots assist in sorting, separating, and processing recyclable materials more efficiently and accurately than manual methods. They help increase the speed and quality of recycling operations.

How do robotics improve the efficiency of recycling plants?

Robotics automate repetitive tasks, reduce human error, and operate continuously without fatigue. This leads to faster processing times, higher throughput, and lower operational costs.

What types of robots are commonly used in recycling?

Common types include robotic arms equipped with sensors and AI for sorting, autonomous mobile robots for material transport, and specialized machines for shredding or compacting recyclables.

Can robotics handle different types of recyclable materials?

Yes, advanced robotics systems use machine learning and sensor technology to identify and sort various materials such as plastics, metals, paper, and glass with high precision.

Do robotics reduce contamination in recycling streams?

Yes, by accurately sorting materials, robots help minimize contamination, which improves the quality of recycled products and increases the value of recycled materials.

Are robotics cost-effective for recycling facilities?

While initial investment can be high, robotics often lead to long-term cost savings through increased efficiency, reduced labor costs, and improved material recovery rates.

How do robotics impact worker safety in recycling operations?

Robotics reduce the need for humans to perform hazardous tasks, lowering the risk of injuries and exposure to harmful substances in recycling facilities.

Is artificial intelligence used in recycling robotics?

Yes, AI enables robots to learn and improve sorting accuracy over time by recognizing patterns and adapting to new types of materials.

What challenges exist in implementing robotics in recycling?

Challenges include high upfront costs, the need for specialized maintenance, integration with existing systems, and adapting to the variability of waste streams.

How do robotics contribute to sustainability in recycling?

By improving sorting accuracy and processing efficiency, robotics increase the amount of material that can be recycled, reducing landfill waste and conserving natural resources.