The Internet of Things (IoT) has emerged as a transformative force in various industries, and consumer electronics manufacturing is no exception. By connecting devices and systems through the internet, IoT enables real-time data exchange and communication, leading to enhanced operational efficiency, improved product quality, and a more personalized customer experience. The integration of IoT technologies into manufacturing processes allows companies to gather vast amounts of data from machines, sensors, and products, which can be analyzed to optimize production workflows and drive innovation.

As consumer expectations evolve, manufacturers are increasingly leveraging IoT to stay competitive in a rapidly changing market. In the realm of consumer electronics, where product lifecycles are short and innovation is paramount, the adoption of IoT technologies is not merely advantageous; it is essential. Manufacturers are now able to monitor equipment performance, track inventory levels, and analyze consumer behavior in real-time.

This connectivity fosters a more agile manufacturing environment, enabling companies to respond swiftly to market demands and consumer preferences. As a result, IoT is reshaping the landscape of consumer electronics manufacturing, paving the way for smarter factories and more intelligent products.

Key Takeaways

- IoT is revolutionizing consumer electronics manufacturing by enabling connected devices and data-driven insights.

- IoT is transforming supply chain management in consumer electronics manufacturing by providing real-time visibility and predictive analytics.

- IoT is enhancing product quality and efficiency in consumer electronics manufacturing through remote monitoring and automation.

- IoT-enabled predictive maintenance is reducing downtime and costs in consumer electronics manufacturing by predicting equipment failures.

- IoT is improving customer experience in consumer electronics manufacturing through personalized products and proactive support.

Impact of IoT on Supply Chain Management in Consumer Electronics Manufacturing

The integration of IoT into supply chain management has revolutionized how consumer electronics manufacturers operate. By utilizing connected devices and sensors throughout the supply chain, companies can achieve unprecedented visibility into their operations. For instance, RFID tags and GPS tracking systems allow manufacturers to monitor the location and condition of raw materials and finished products in real-time.

This level of transparency not only enhances inventory management but also reduces the risk of stockouts or overstock situations, which can be detrimental to profitability. Moreover, IoT facilitates better collaboration among supply chain partners. With real-time data sharing, manufacturers can coordinate more effectively with suppliers and distributors, leading to improved demand forecasting and reduced lead times.

For example, if a manufacturer notices a spike in demand for a particular electronic device, they can quickly communicate this information to their suppliers to ensure that the necessary components are available for production. This responsiveness is crucial in an industry characterized by rapid technological advancements and shifting consumer preferences.

Improving Product Quality and Efficiency with IoT in Consumer Electronics Manufacturing

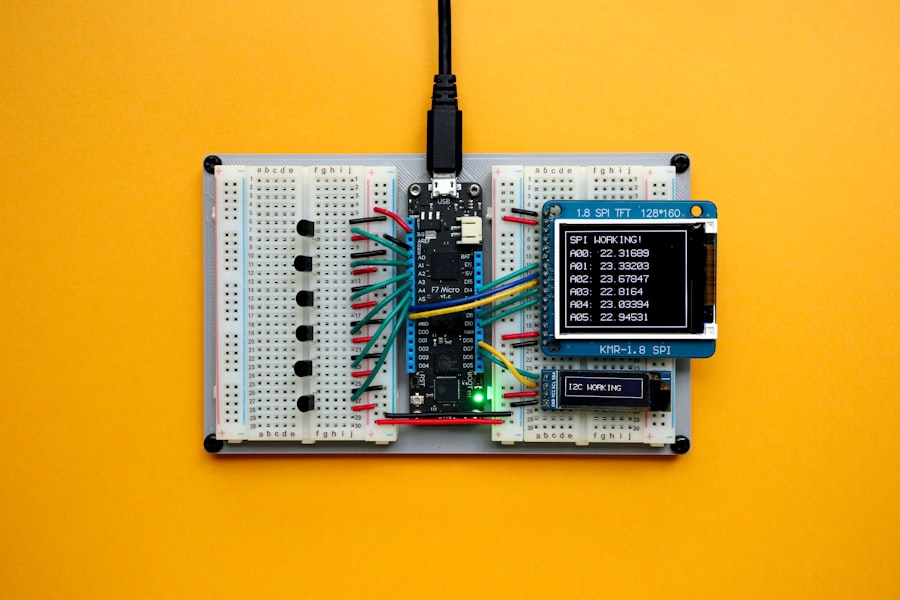

IoT technologies play a pivotal role in enhancing product quality and operational efficiency within consumer electronics manufacturing. By deploying sensors on production lines, manufacturers can collect data on various parameters such as temperature, humidity, and machine performance. This data can be analyzed to identify patterns and anomalies that may indicate potential quality issues.

For instance, if a particular machine consistently produces components that fall outside of specified tolerances, manufacturers can take corrective action before defective products reach the market. Additionally, IoT enables manufacturers to implement advanced quality control measures through automation. Automated inspection systems equipped with machine vision technology can detect defects in real-time during the production process.

This not only reduces the likelihood of faulty products being shipped to customers but also minimizes waste and rework costs. By ensuring that only high-quality products reach consumers, manufacturers can enhance their brand reputation and foster customer loyalty.

IoT-enabled Predictive Maintenance in Consumer Electronics Manufacturing

Predictive maintenance is one of the most significant applications of IoT in consumer electronics manufacturing. Traditional maintenance practices often rely on scheduled inspections or reactive measures after equipment failure occurs. However, with IoT-enabled predictive maintenance, manufacturers can leverage data analytics to anticipate equipment failures before they happen.

Sensors installed on machinery continuously monitor performance metrics such as vibration, temperature, and operational hours. This data is then analyzed using machine learning algorithms to predict when maintenance is required. For example, if a machine shows signs of excessive vibration that deviates from its normal operating range, the system can alert maintenance personnel to investigate further.

This proactive approach not only minimizes downtime but also extends the lifespan of equipment by preventing catastrophic failures. As a result, manufacturers can maintain higher levels of productivity while reducing maintenance costs associated with unplanned repairs.

Enhancing Customer Experience through IoT in Consumer Electronics Manufacturing

The impact of IoT extends beyond manufacturing processes; it also significantly enhances the customer experience in the consumer electronics sector. Smart devices equipped with IoT capabilities can provide users with personalized experiences tailored to their preferences and behaviors.

This level of personalization fosters a deeper connection between consumers and their devices. Furthermore, IoT enables manufacturers to gather valuable feedback from customers through connected products. By analyzing usage data and customer interactions, companies can gain insights into how their products are being used in real-world scenarios.

This information can inform future product development efforts, allowing manufacturers to create devices that better meet consumer needs. Additionally, manufacturers can offer remote troubleshooting and support services through IoT connectivity, enhancing customer satisfaction by resolving issues quickly and efficiently.

IoT and Data Analytics in Consumer Electronics Manufacturing

The synergy between IoT and data analytics is a game-changer for consumer electronics manufacturing. The vast amounts of data generated by connected devices provide manufacturers with a wealth of information that can be harnessed for strategic decision-making. Advanced analytics tools enable companies to process this data effectively, uncovering insights that drive operational improvements and innovation.

For instance, predictive analytics can help manufacturers identify trends in consumer behavior or anticipate shifts in market demand. By analyzing historical sales data alongside real-time information from connected devices, companies can make informed decisions about product development, marketing strategies, and inventory management. Additionally, data analytics can enhance supply chain efficiency by optimizing logistics routes based on real-time traffic conditions or weather patterns.

Challenges and Opportunities of Implementing IoT in Consumer Electronics Manufacturing

While the benefits of IoT in consumer electronics manufacturing are substantial, there are also significant challenges that companies must navigate during implementation. One major concern is cybersecurity; as devices become increasingly interconnected, the risk of cyberattacks grows. Manufacturers must invest in robust security measures to protect sensitive data and ensure the integrity of their systems.

This includes implementing encryption protocols, conducting regular security audits, and training employees on best practices for cybersecurity. Another challenge lies in the integration of legacy systems with new IoT technologies. Many manufacturers operate with established processes and equipment that may not be compatible with modern IoT solutions.

Transitioning to an IoT-enabled environment requires careful planning and investment in new infrastructure. However, these challenges also present opportunities for innovation. Companies that successfully implement IoT solutions can gain a competitive edge by improving efficiency, reducing costs, and enhancing customer satisfaction.

Future Trends in IoT for Consumer Electronics Manufacturing

Looking ahead, several trends are poised to shape the future of IoT in consumer electronics manufacturing. One notable trend is the increasing adoption of edge computing, which allows data processing to occur closer to the source rather than relying solely on centralized cloud servers. This shift enables faster decision-making and reduces latency in real-time applications such as autonomous quality control systems.

Additionally, advancements in artificial intelligence (AI) will further enhance the capabilities of IoT systems in manufacturing. AI algorithms can analyze complex datasets generated by connected devices to identify patterns that humans may overlook. This will lead to more accurate predictive maintenance models and improved quality control processes.

Moreover, sustainability will become a central focus for manufacturers as consumers increasingly demand environmentally friendly products. IoT technologies can facilitate more efficient resource management by optimizing energy consumption during production processes or enabling circular economy practices through better tracking of product lifecycles.

From supply chain management to customer experience enhancement, the potential applications are vast and varied. As technology continues to evolve, manufacturers must remain agile and proactive in adopting these innovations to thrive in an increasingly competitive landscape.

One related article to How IoT is Changing Consumer Electronics Manufacturing is “Unlock a New World of Possibilities with Samsung Galaxy Z Fold4.” This article discusses the innovative features and capabilities of the latest Samsung Galaxy Z Fold4 smartphone. With advancements in IoT technology, devices like the Galaxy Z Fold4 are able to offer users a seamless and connected experience. To learn more about this cutting-edge device, check out the article here.

FAQs

What is IoT?

IoT stands for Internet of Things, which refers to the network of physical devices, vehicles, home appliances, and other items embedded with electronics, software, sensors, actuators, and connectivity which enables these things to connect and exchange data.

How is IoT impacting consumer electronics manufacturing?

IoT is revolutionizing consumer electronics manufacturing by enabling the creation of smart, connected devices that can communicate with each other and with users. This has led to the development of innovative products such as smart home devices, wearable technology, and connected appliances.

What are the benefits of IoT in consumer electronics manufacturing?

Some of the benefits of IoT in consumer electronics manufacturing include improved product functionality, enhanced user experience, predictive maintenance, remote monitoring and control, and the ability to gather and analyze data for product improvement and innovation.

What are some examples of IoT-enabled consumer electronics products?

Examples of IoT-enabled consumer electronics products include smart thermostats, connected home security systems, wearable fitness trackers, smart refrigerators, and voice-activated smart speakers.

How is IoT changing the production process in consumer electronics manufacturing?

IoT is changing the production process in consumer electronics manufacturing by enabling the use of advanced automation, predictive maintenance, real-time monitoring of production lines, and the ability to gather and analyze data to optimize manufacturing processes.

What are the challenges of implementing IoT in consumer electronics manufacturing?

Challenges of implementing IoT in consumer electronics manufacturing include data security and privacy concerns, interoperability issues, the need for skilled personnel to manage IoT systems, and the cost of implementing IoT technology.