The landscape of supply chain management has undergone a significant transformation in recent years, primarily driven by advancements in technology and the increasing complexity of global trade. Automation has emerged as a pivotal force in this evolution, reshaping how businesses operate and manage their supply chains. By integrating automated systems and processes, organizations can enhance efficiency, reduce costs, and improve overall service delivery.

The shift towards automation is not merely a trend; it represents a fundamental change in how supply chains are designed and executed. As companies strive to remain competitive in an ever-evolving marketplace, the adoption of automation technologies has become essential. From inventory management to order fulfillment, automation streamlines operations, minimizes human error, and accelerates decision-making processes.

This article delves into the multifaceted role of automation in supply chain management, exploring its benefits, key technologies, successful case studies, challenges, best practices for integration, and future trends that promise to further revolutionize the field.

Key Takeaways

- Automation in supply chain management involves the use of technology to streamline and optimize the flow of goods and services from the point of origin to the point of consumption.

- The benefits of automation in supply chain management include increased efficiency, reduced costs, improved accuracy, better inventory management, and enhanced customer satisfaction.

- Key technologies used in automation for supply chain management include artificial intelligence, robotics, Internet of Things (IoT), blockchain, and advanced analytics.

- Case studies of successful implementation of automation in supply chain management include companies like Amazon, Walmart, and UPS, who have leveraged automation to improve their operations and customer experience.

- Challenges and considerations for implementing automation in supply chain management include initial investment costs, integration with existing systems, workforce training, cybersecurity risks, and potential job displacement.

Benefits of Automation in Supply Chain Management

The benefits of automation in supply chain management are manifold, significantly impacting operational efficiency and cost-effectiveness. One of the most notable advantages is the enhancement of speed and accuracy in various processes. Automated systems can process orders, manage inventory levels, and track shipments with remarkable precision, reducing the likelihood of errors that can arise from manual handling.

For instance, automated inventory management systems can provide real-time data on stock levels, enabling businesses to make informed decisions about reordering and stock allocation. Moreover, automation facilitates better resource allocation by optimizing labor costs and minimizing waste. By automating repetitive tasks such as data entry or order processing, companies can redirect human resources towards more strategic activities that require critical thinking and creativity.

This not only boosts employee morale but also enhances productivity across the organization. Additionally, automation can lead to significant cost savings by reducing operational overheads associated with manual processes and improving supply chain visibility, which allows for more effective demand forecasting and inventory management.

Key Technologies Used in Automation for Supply Chain Management

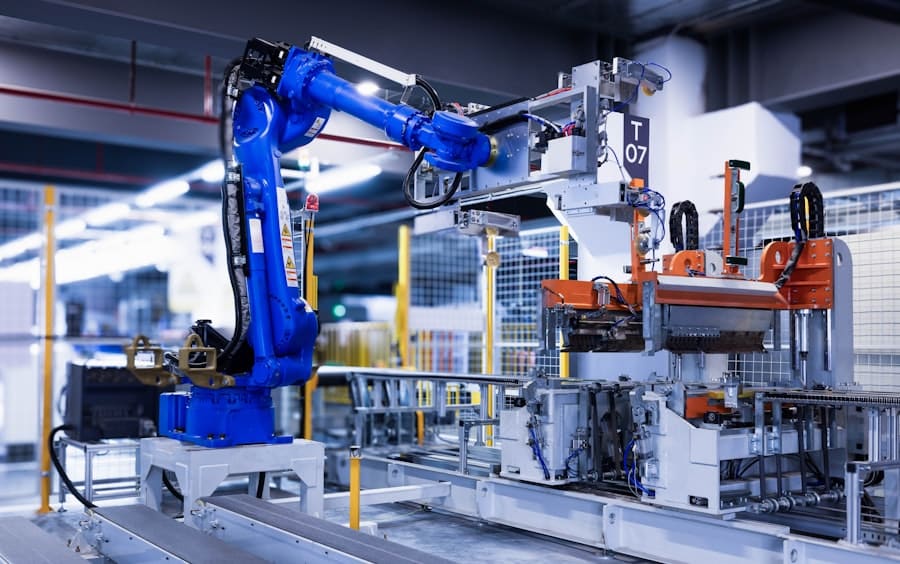

Several key technologies underpin the automation of supply chain management, each contributing unique capabilities that enhance operational efficiency. One of the most prominent technologies is robotics process automation (RPA), which enables organizations to automate routine tasks through software bots. RPA can be employed in various areas such as order processing, invoicing, and data reconciliation, allowing for faster turnaround times and reduced human intervention.

Another critical technology is the Internet of Things (IoT), which connects devices and sensors across the supply chain to collect and analyze data in real time. IoT devices can monitor equipment performance, track shipments, and provide insights into inventory levels, enabling businesses to respond swiftly to changes in demand or supply disruptions. Furthermore, artificial intelligence (AI) and machine learning algorithms are increasingly being integrated into supply chain operations to enhance decision-making processes.

These technologies can analyze vast amounts of data to identify patterns, predict trends, and optimize logistics routes, ultimately leading to more efficient supply chain management.

Case Studies of Successful Implementation of Automation in Supply Chain Management

Numerous organizations have successfully implemented automation within their supply chains, yielding impressive results that serve as benchmarks for others. One notable example is Amazon, which has revolutionized e-commerce through its extensive use of automation technologies. The company employs a sophisticated network of robots in its fulfillment centers to assist with picking and packing orders.

These robots work alongside human employees to streamline operations, significantly reducing order processing times and enhancing overall efficiency. Another compelling case is that of Walmart, which has integrated automation into its supply chain management through advanced inventory management systems. By utilizing RFID technology and automated data collection methods, Walmart can maintain accurate inventory levels across its vast network of stores and distribution centers.

This level of visibility allows the company to optimize stock replenishment processes and reduce instances of stockouts or overstock situations. The result is a more agile supply chain that can respond effectively to customer demands while minimizing excess inventory costs.

Challenges and Considerations for Implementing Automation in Supply Chain Management

Despite the numerous advantages associated with automation in supply chain management, organizations must navigate several challenges when implementing these technologies. One significant hurdle is the initial investment required for automation solutions. The costs associated with acquiring new technologies, training employees, and integrating systems can be substantial, particularly for small to medium-sized enterprises (SMEs).

As a result, businesses must carefully assess their return on investment (ROI) before committing to automation initiatives. Additionally, there are concerns related to workforce displacement as automation takes over tasks traditionally performed by humans. While automation can enhance productivity and efficiency, it may also lead to job losses or require employees to adapt to new roles that necessitate different skill sets.

Organizations must address these concerns by investing in employee training programs that equip workers with the skills needed to thrive in an increasingly automated environment. Furthermore, fostering a culture of adaptability and continuous learning will be crucial for ensuring a smooth transition to automated processes.

Best Practices for Integrating Automation into Supply Chain Management

To maximize the benefits of automation in supply chain management, organizations should adhere to several best practices during the integration process. First and foremost, it is essential to conduct a thorough assessment of existing processes to identify areas where automation can deliver the most value. This involves analyzing workflows, pinpointing bottlenecks, and determining which tasks are most suitable for automation.

This approach enables businesses to evaluate the effectiveness of automation solutions while minimizing risks associated with large-scale changes. Additionally, involving employees in the decision-making process can foster buy-in and ensure that their insights are considered when selecting automation tools.

Another critical best practice is to establish clear metrics for measuring the success of automation initiatives. By defining key performance indicators (KPIs) related to efficiency gains, cost savings, and customer satisfaction, organizations can track progress and make data-driven adjustments as needed.

Future Trends and Innovations in Automation for Supply Chain Management

As technology continues to advance at a rapid pace, several future trends are poised to shape the landscape of automation in supply chain management. One such trend is the increasing adoption of autonomous vehicles for transportation and logistics operations. Companies are exploring the use of drones for last-mile delivery and self-driving trucks for long-haul transportation.

These innovations promise to enhance delivery speed while reducing labor costs associated with traditional transportation methods. Additionally, advancements in AI and machine learning will further refine predictive analytics capabilities within supply chains. As these technologies evolve, organizations will be able to leverage more sophisticated algorithms that analyze historical data alongside real-time information to forecast demand with greater accuracy.

This enhanced forecasting ability will enable businesses to optimize inventory levels and reduce waste while ensuring they meet customer expectations. Furthermore, blockchain technology is gaining traction as a means of enhancing transparency and traceability within supply chains. By providing a secure and immutable ledger for transactions, blockchain can facilitate better collaboration among supply chain partners while reducing fraud and errors associated with manual record-keeping.

As more organizations recognize the value of blockchain in automating processes such as contract management and payment reconciliation, its adoption is expected to grow significantly.

The Impact of Automation on the Future of Supply Chain Management

The impact of automation on supply chain management is profound and far-reaching. As businesses continue to embrace technological advancements, they are not only improving operational efficiency but also redefining their competitive strategies in an increasingly complex global marketplace. The integration of automation technologies enables organizations to respond swiftly to market changes while enhancing customer satisfaction through improved service delivery.

Looking ahead, it is clear that automation will play an integral role in shaping the future of supply chains across various industries. As companies navigate the challenges associated with implementation and strive for continuous improvement, those that successfully leverage automation will position themselves as leaders in their respective markets. The journey towards fully automated supply chains may be fraught with obstacles; however, the potential rewards—greater efficiency, reduced costs, and enhanced agility—make it a pursuit worth undertaking for organizations committed to thriving in the digital age.

In the rapidly evolving world of supply chain management, automation plays a crucial role in enhancing efficiency and reducing operational costs. By integrating advanced technologies, businesses can streamline their processes, leading to improved productivity and customer satisfaction. For those interested in exploring how technology can optimize other areas, such as user experience design, the article on Best Software for UX provides valuable insights into selecting the right tools to enhance user interactions and design workflows. Both automation in supply chain management and UX design software highlight the transformative power of technology in modern business operations.

FAQs

What is supply chain management?

Supply chain management is the process of overseeing and optimizing the flow of goods, services, and information from the initial production stage to the final delivery to the customer.

What is automation in supply chain management?

Automation in supply chain management involves the use of technology and software to streamline and optimize various processes such as inventory management, order fulfillment, and logistics.

How does automation streamline supply chain management?

Automation streamlines supply chain management by reducing manual tasks, improving accuracy, increasing efficiency, and providing real-time visibility into the entire supply chain.

What are some examples of automation in supply chain management?

Examples of automation in supply chain management include automated inventory tracking systems, robotic process automation for order processing, and automated transportation management systems.

What are the benefits of automation in supply chain management?

The benefits of automation in supply chain management include cost savings, improved accuracy, faster order processing, better inventory management, and enhanced overall efficiency.

What are the challenges of implementing automation in supply chain management?

Challenges of implementing automation in supply chain management may include initial investment costs, integration with existing systems, and the need for employee training on new technologies.