Augmented Reality (AR) has emerged as a transformative technology in various sectors, particularly in industrial settings. By overlaying digital information onto the physical world, AR enhances the way workers interact with their environment, providing real-time data and guidance that can significantly improve efficiency and accuracy. This technology is not merely a novelty; it represents a paradigm shift in how tasks are performed, especially in complex environments such as manufacturing, maintenance, and assembly lines.

The integration of AR into industrial processes allows for a more intuitive understanding of tasks, reducing the cognitive load on workers and enabling them to focus on execution rather than interpretation. The application of AR in industrial settings is particularly relevant in an era where rapid technological advancements demand a workforce that is not only skilled but also adaptable. Traditional methods of training and instruction often fall short in meeting these demands, leading to inefficiencies and increased error rates.

AR addresses these shortcomings by providing immersive experiences that can be tailored to individual learning styles and paces.

Key Takeaways

- AR in industrial settings enhances traditional instructional manuals

- Traditional instructional manuals have limitations in industrial settings

- AR provides benefits such as improved efficiency and reduced errors in industrial settings

- Successful case studies demonstrate the effectiveness of AR in industrial settings

- AR enhances training and onboarding processes in industrial settings

The Limitations of Traditional Instructional Manuals

Traditional instructional manuals have long been the cornerstone of training and operational guidance in industrial settings. However, they come with significant limitations that can hinder productivity and learning. One of the primary drawbacks is their static nature; manuals are often text-heavy and lack interactive elements that engage users.

This can lead to misunderstandings or misinterpretations of critical information, especially when dealing with complex machinery or intricate processes. Workers may struggle to visualize how components fit together or how to execute specific tasks, resulting in increased downtime and potential safety hazards. Moreover, traditional manuals are often not updated in real-time, which can lead to discrepancies between the documented procedures and the actual practices on the shop floor.

In fast-paced industrial environments, changes in processes or equipment can render manuals obsolete almost immediately. This disconnect can create confusion among employees who rely on outdated information, ultimately affecting their performance and the overall efficiency of operations. Additionally, the physical nature of printed manuals can make them cumbersome to use in dynamic work environments where hands-free operation is essential.

The Benefits of Using AR for Instructional Manuals in Industrial Settings

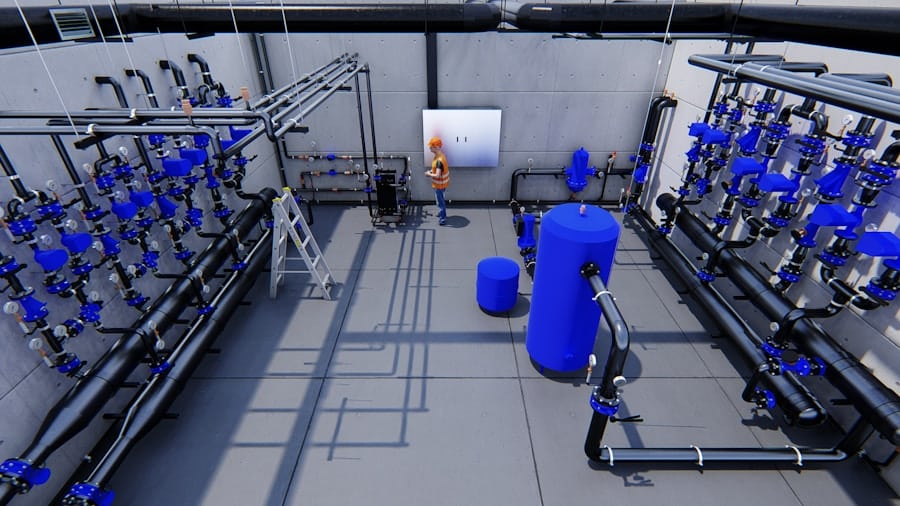

The integration of AR into instructional manuals offers a multitude of benefits that address the limitations of traditional methods. One of the most significant advantages is the ability to provide interactive, visual guidance that enhances comprehension. With AR, workers can see 3D models of equipment or processes overlaid onto their real-world environment, allowing them to visualize complex tasks in a way that static images or text cannot achieve.

This immersive experience not only aids in understanding but also boosts retention rates, as users are more likely to remember information presented in an engaging format. Furthermore, AR can facilitate real-time updates and modifications to instructional content. As processes evolve or new equipment is introduced, AR systems can be easily adjusted to reflect these changes without the need for extensive reprinting or redistribution of physical manuals.

This ensures that workers always have access to the most current information, reducing the risk of errors caused by outdated procedures. Additionally, AR can provide contextual information based on the worker’s location or task at hand, offering tailored support that enhances decision-making and problem-solving capabilities.

Case Studies of Successful Implementation of AR in Industrial Settings

Several companies have successfully implemented AR technologies in their industrial operations, showcasing the tangible benefits of this innovative approach. For instance, Boeing has utilized AR for wiring assembly in its aircraft manufacturing process. By equipping technicians with AR glasses that display step-by-step instructions and 3D visualizations directly onto the aircraft components, Boeing has reported a significant reduction in assembly time and errors.

This application not only streamlines the workflow but also enhances safety by allowing workers to focus on their tasks without constantly referring to physical manuals. Another notable example is Siemens, which has integrated AR into its maintenance procedures for gas turbines. Technicians use AR devices to access real-time data and visual instructions while performing repairs or inspections.

This approach has led to improved accuracy and efficiency, as technicians can visualize complex systems and receive immediate feedback on their actions. The success of these implementations highlights how AR can revolutionize traditional practices, leading to enhanced productivity and reduced operational costs.

How AR Enhances Training and Onboarding Processes in Industrial Settings

AR technology plays a pivotal role in enhancing training and onboarding processes within industrial environments. Traditional training methods often involve lengthy sessions that may not effectively engage new employees or provide them with practical experience. In contrast, AR allows for immersive training experiences where new hires can interact with virtual simulations of equipment or processes before they ever step onto the shop floor.

This hands-on approach not only accelerates the learning curve but also instills confidence in new employees as they become familiar with their roles. Moreover, AR can facilitate continuous learning by providing ongoing support even after initial training is complete. Workers can access AR-guided instructions during their tasks, allowing them to refresh their knowledge or learn new skills on-the-job.

This adaptability is particularly beneficial in industries where technology and processes are constantly evolving. By fostering a culture of continuous improvement and learning through AR, companies can ensure that their workforce remains skilled and capable of meeting future challenges.

The Future of AR in Instructional Manuals for Industrial Settings

The future of AR in instructional manuals for industrial settings appears promising as advancements in technology continue to unfold. With the development of more sophisticated AR devices and software, we can expect even greater levels of interactivity and immersion. For instance, the integration of artificial intelligence (AI) with AR could lead to personalized training experiences that adapt to individual learning styles and preferences.

AI algorithms could analyze a worker’s performance in real-time and adjust the instructional content accordingly, providing targeted support where it is needed most. Additionally, as 5G technology becomes more widespread, the potential for AR applications will expand significantly. Enhanced connectivity will enable real-time data sharing and collaboration among teams across different locations, allowing for remote assistance and guidance through AR interfaces.

This could be particularly beneficial for global companies with operations spread across multiple sites, as experts could provide support without being physically present. The convergence of these technologies will likely redefine how instructional manuals are created and utilized, making them more dynamic and responsive to the needs of modern industrial environments.

Overcoming Challenges and Barriers to Implementing AR in Industrial Settings

Despite its numerous advantages, the implementation of AR in industrial settings is not without challenges. One significant barrier is the initial investment required for AR technology, including hardware, software development, and training for employees on how to use these new tools effectively. Many organizations may hesitate to allocate resources toward such initiatives without clear evidence of return on investment (ROI).

To overcome this challenge, companies must conduct thorough assessments of potential benefits versus costs and consider pilot programs that demonstrate the value of AR before committing to full-scale implementation. Another challenge lies in ensuring that all employees are comfortable with using AR technology.

To address this issue, companies should prioritize comprehensive training programs that not only teach employees how to use AR tools but also emphasize the benefits they bring to daily operations. Engaging employees early in the process by soliciting their feedback and involving them in decision-making can also foster a sense of ownership and acceptance of new technologies.

Best Practices for Creating Effective AR Instructional Manuals for Industrial Settings

Creating effective AR instructional manuals requires careful consideration of several best practices to ensure they meet the needs of users while maximizing the benefits of the technology. First and foremost, content should be designed with user experience in mind; this means prioritizing clarity and simplicity over complexity. Visual elements should be intuitive and easy to navigate, allowing users to quickly access relevant information without feeling overwhelmed.

Additionally, incorporating feedback mechanisms within AR applications can enhance their effectiveness. Users should have the ability to provide input on their experiences with the instructional content, allowing organizations to make continuous improvements based on real-world usage. Furthermore, it is essential to ensure that AR content is regularly updated to reflect any changes in processes or equipment accurately.

By following these best practices, companies can create AR instructional manuals that not only enhance learning but also drive operational efficiency in industrial settings.

A related article to How AR Is Improving Instructional Manuals in Industrial Settings is “What Is Special About the iPhone 14 Pro?” This article discusses the latest features and advancements in the iPhone 14 Pro, highlighting how technology continues to evolve and improve user experiences. To read more about the latest trends in technology, check out this article.

FAQs

What is AR?

AR stands for Augmented Reality, which is a technology that superimposes digital information such as images, videos, or 3D models onto the real world environment.

How is AR improving instructional manuals in industrial settings?

AR is improving instructional manuals in industrial settings by providing workers with real-time, interactive guidance and information overlaid onto the physical equipment they are working on. This can help improve efficiency, accuracy, and safety in industrial operations.

What are the benefits of using AR in instructional manuals for industrial settings?

Some benefits of using AR in instructional manuals for industrial settings include improved training and onboarding processes, reduced errors and downtime, increased productivity, and enhanced safety for workers.

How does AR technology work in instructional manuals for industrial settings?

AR technology works in instructional manuals for industrial settings by using devices such as smart glasses or tablets to display digital information and instructions overlaid onto the physical equipment or machinery being worked on. This information can include step-by-step guides, 3D models, or real-time data.

Are there any challenges or limitations to using AR in instructional manuals for industrial settings?

Some challenges or limitations to using AR in instructional manuals for industrial settings include the initial cost of implementing the technology, potential technical issues or compatibility with existing systems, and the need for proper training and support for workers to effectively use AR technology.