Augmented Reality (AR) has emerged as a transformative technology across various sectors, and the mechanical industry is no exception. By overlaying digital information onto the physical world, AR enhances the way mechanics interact with machinery, tools, and components. This technology allows for a more intuitive understanding of complex systems, enabling mechanics to visualize internal components and processes that would otherwise remain hidden.

As industries increasingly adopt AR, it is reshaping traditional practices, improving efficiency, and reducing errors in mechanical work. The integration of AR into the mechanical industry is not merely a trend; it represents a significant shift in how professionals approach their tasks. With the ability to visualize intricate details in real-time, mechanics can diagnose issues more effectively and perform repairs with greater precision.

This technology is particularly beneficial in an era where machinery is becoming increasingly sophisticated, requiring a deeper understanding of internal workings. As AR continues to evolve, its applications in the mechanical field are expanding, promising to enhance productivity and safety while minimizing downtime.

Key Takeaways

- AR technology is revolutionizing the mechanical industry by providing innovative solutions for visualizing internal components and enhancing training and education opportunities for mechanics.

- Using AR in the mechanical industry offers benefits such as improved visualization of internal components, enhanced efficiency in maintenance and repair tasks, and reduced downtime for equipment.

- AR technology works for mechanics by overlaying digital information onto the physical environment, providing real-time guidance and instructions for complex tasks, and enabling remote assistance from experts.

- Case studies of AR implementation in mechanical work demonstrate its effectiveness in improving accuracy, reducing errors, and increasing productivity in various maintenance and repair tasks.

- The future of AR in the mechanical industry holds promising opportunities for further advancements in training and education, remote assistance, and the development of more sophisticated AR applications tailored to specific mechanical tasks. However, challenges and limitations such as cost, technical complexity, and user acceptance need to be addressed for widespread adoption.

The Benefits of Using AR for Visualizing Internal Components

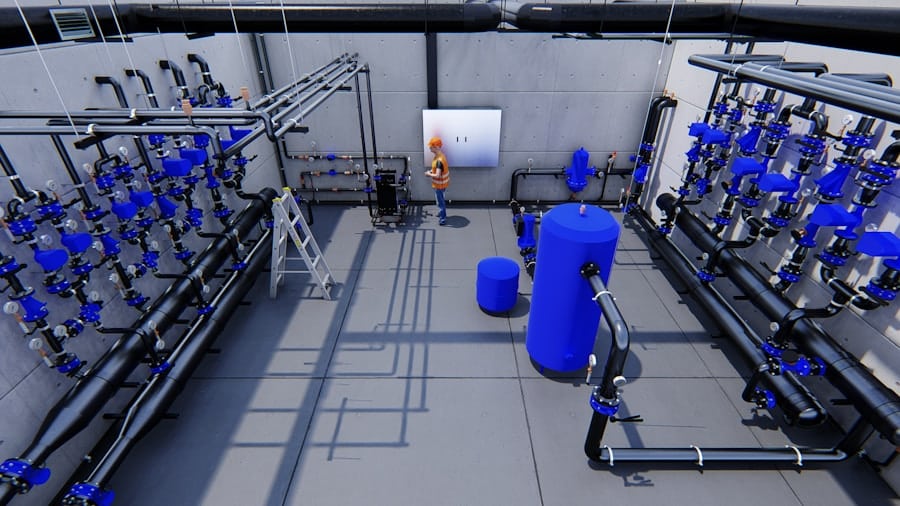

One of the most significant advantages of AR in the mechanical industry is its ability to visualize internal components without disassembling machinery. Traditional methods often require mechanics to rely on manuals or diagrams that may not accurately represent the current state of a machine. In contrast, AR provides a dynamic view of components, allowing mechanics to see how parts fit together and function in real-time.

This capability not only streamlines the diagnostic process but also enhances the accuracy of repairs. For instance, consider a scenario where a mechanic is tasked with diagnosing a malfunctioning engine. With AR technology, they can use smart glasses or mobile devices to overlay digital schematics directly onto the engine.

This visualization can highlight specific components, such as sensors or valves, that may be causing issues. By providing a clear view of the internal structure, AR reduces the time spent on troubleshooting and minimizes the risk of overlooking critical elements. Furthermore, this technology can facilitate remote assistance, where experts can guide on-site mechanics through complex repairs by sharing visual information in real-time.

How AR Technology Works for Mechanics

AR technology operates by integrating digital content with the physical environment through various devices such as smartphones, tablets, or specialized AR glasses. The core of AR involves computer vision, simultaneous localization and mapping (SLAM), and depth tracking. These technologies work together to recognize physical objects and overlay relevant digital information accurately.

For mechanics, this means that when they point their device at a machine or component, the AR system can identify it and display pertinent data, such as maintenance history, operational parameters, or assembly instructions. The process begins with capturing the environment using cameras and sensors embedded in AR devices. These devices analyze the surroundings to create a 3D map, allowing them to understand spatial relationships between objects.

Once the environment is mapped, mechanics can interact with digital overlays that provide contextual information. For example, when inspecting a hydraulic system, an AR application might display pressure readings or fluid levels directly on the corresponding components. This immediate access to data enhances decision-making and empowers mechanics to perform their tasks with greater confidence.

Case Studies of AR Implementation in Mechanical Work

Several companies have successfully implemented AR technology within their mechanical operations, showcasing its potential benefits. One notable example is Boeing, which has integrated AR into its aircraft assembly processes. By using AR headsets, technicians can access 3D models of aircraft components while working on the assembly line.

This approach has significantly reduced assembly time and errors, as workers can visualize complex wiring and component placements without needing extensive reference materials. Another compelling case is that of Ford Motor Company, which has utilized AR for vehicle maintenance training. By providing technicians with AR tools that overlay repair instructions directly onto vehicles, Ford has improved training efficiency and reduced the learning curve for new employees.

Trainees can see step-by-step procedures in real-time as they work on actual vehicles, leading to better retention of information and enhanced practical skills. These case studies illustrate how AR not only improves operational efficiency but also enhances workforce training and development within the mechanical industry.

Training and Education Opportunities for Mechanics Using AR

The educational landscape for mechanics is evolving with the introduction of AR technology. Training programs are increasingly incorporating AR simulations to provide hands-on experience without the risks associated with working on actual machinery. For instance, vocational schools and technical colleges are adopting AR platforms that allow students to practice repairs and diagnostics in a controlled environment.

This immersive learning experience helps students grasp complex concepts more effectively than traditional classroom settings. Moreover, AR can facilitate ongoing education for seasoned mechanics by providing access to updated information about new technologies and repair techniques. As machinery evolves, so too must the skills of those who maintain it.

With AR applications that deliver real-time updates and training modules directly to mechanics in the field, professionals can stay current with industry advancements without needing extensive retraining sessions. This continuous learning approach not only enhances individual skill sets but also contributes to overall workplace efficiency.

The Future of AR in the Mechanical Industry

Looking ahead, the future of AR in the mechanical industry appears promising as advancements in technology continue to unfold. The integration of artificial intelligence (AI) with AR could further enhance its capabilities by enabling predictive maintenance solutions. For example, AI algorithms could analyze data from machinery sensors and predict potential failures before they occur.

When combined with AR visualizations, mechanics could receive alerts about impending issues along with visual guidance on how to address them proactively. Additionally, as 5G technology becomes more widespread, the potential for real-time data sharing will increase significantly. Mechanics will be able to access cloud-based resources instantly, allowing for seamless collaboration with remote experts or engineers during complex repairs.

This connectivity will enhance problem-solving capabilities and reduce downtime for businesses reliant on heavy machinery.

Challenges and Limitations of AR for Mechanics

Despite its numerous advantages, the implementation of AR in the mechanical industry is not without challenges. One significant limitation is the initial cost associated with acquiring AR hardware and software solutions. For smaller businesses or workshops operating on tight budgets, investing in advanced technology may seem daunting.

Additionally, there may be resistance from employees who are accustomed to traditional methods and may require time to adapt to new technologies. Another challenge lies in ensuring that AR content remains accurate and up-to-date. As machinery evolves and new models are introduced, maintaining an extensive library of digital overlays becomes essential yet resource-intensive.

Companies must invest in continuous content development to ensure that mechanics have access to reliable information at all times. Furthermore, technical issues such as connectivity problems or software glitches can hinder the effectiveness of AR applications in critical situations.

The Impact of AR on the Mechanical Industry

The impact of augmented reality on the mechanical industry is profound and multifaceted. By enhancing visualization capabilities and streamlining processes, AR is revolutionizing how mechanics approach their work. From improving diagnostic accuracy to facilitating training opportunities, this technology is reshaping traditional practices and paving the way for a more efficient future.

As industries continue to embrace digital transformation, the role of AR will likely expand further within mechanical operations.

The ongoing evolution of AR technology promises to enhance productivity, safety, and overall effectiveness in mechanical work environments, ultimately leading to a more innovative and responsive industry landscape.

A related article to “How AR Is Helping Mechanics Visualize Internal Components of Machinery” is “Best Free Drawing Software for Digital Artists in 2023” which discusses the top tools available for digital artists to create stunning artwork. This article provides valuable insights into the latest trends in digital art software and can be found here.

FAQs

What is AR?

AR stands for Augmented Reality, which is a technology that superimposes computer-generated images onto the user’s view of the real world, providing a composite view.

How is AR being used in the field of mechanics?

AR is being used in the field of mechanics to help visualize internal components of machinery. It allows mechanics to see virtual representations of the internal parts of a machine overlaid onto the physical machine, making it easier to diagnose and repair issues.

What are the benefits of using AR for mechanics?

Using AR allows mechanics to visualize internal components without having to disassemble the machinery, saving time and reducing the risk of errors. It also provides a more intuitive way to understand complex machinery and identify potential issues.

What kind of machinery can AR be used for?

AR can be used for a wide range of machinery, including but not limited to engines, turbines, pumps, and other industrial equipment.

Are there any limitations to using AR for visualizing internal components of machinery?

One limitation of using AR for visualizing internal components of machinery is the need for compatible hardware and software. Additionally, the accuracy of the virtual representations may vary depending on the quality of the AR technology being used.