Augmented Reality (AR) technology has emerged as a transformative force across various industries, and inventory management is no exception. By overlaying digital information onto the physical world, AR devices provide a unique interface that enhances the way businesses track, manage, and optimize their inventory. The integration of AR into inventory management systems allows for real-time data visualization, improved accuracy, and streamlined processes, ultimately leading to increased efficiency and reduced operational costs.

As companies strive to keep pace with the demands of modern supply chains, the adoption of AR devices is becoming increasingly prevalent. The evolution of AR technology has been driven by advancements in hardware and software capabilities, making it more accessible and practical for businesses. From smart glasses to mobile applications, AR devices can cater to various operational needs within inventory management.

This technology not only aids in the physical handling of goods but also enhances decision-making processes by providing critical information at the point of need. As organizations seek to leverage these innovations, understanding the role of AR devices in inventory management becomes essential for staying competitive in a rapidly changing marketplace.

Key Takeaways

- AR devices improve inventory tracking by providing real-time data and hands-free operation.

- Enhanced accuracy in inventory counts is achieved through AR-assisted scanning and verification.

- AR technology streamlines inventory replenishment by alerting staff to low stock levels promptly.

- Visualization features of AR help organize inventory more efficiently and reduce errors.

- Integration with existing management systems enables seamless data flow and better decision-making.

The Role of AR Devices in Streamlining Inventory Tracking

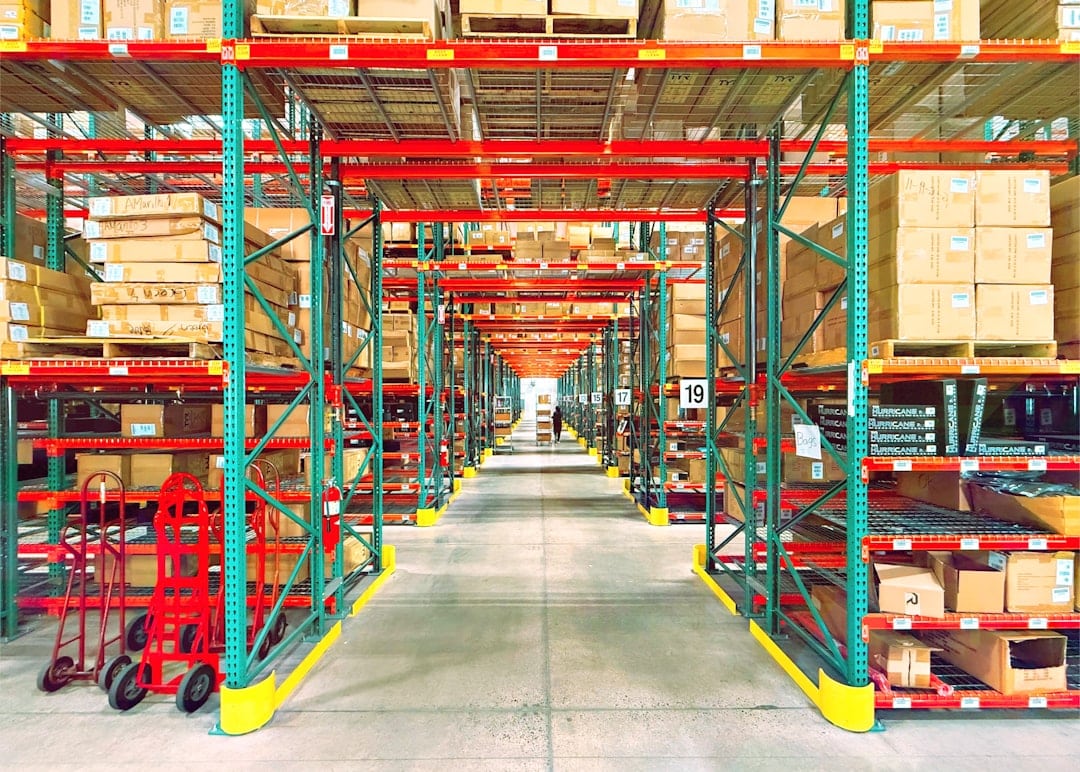

AR devices play a pivotal role in streamlining inventory tracking by providing real-time data and visual cues that enhance operational efficiency. Traditional inventory tracking methods often rely on manual processes, which can be time-consuming and prone to human error. In contrast, AR technology enables workers to visualize inventory data directly in their field of view, allowing them to quickly locate items, verify stock levels, and update records without the need for cumbersome paperwork or handheld scanners.

For instance, a warehouse employee equipped with AR glasses can see an overlay of item locations and quantities as they navigate through aisles, significantly reducing the time spent searching for products. Moreover, AR devices facilitate better communication among team members by providing a shared visual context. When multiple employees are involved in inventory management tasks, AR can help synchronize their efforts by displaying real-time updates on stock levels and locations.

This collaborative approach minimizes misunderstandings and ensures that everyone is on the same page regarding inventory status. For example, if one employee is restocking shelves while another is picking items for shipment, both can benefit from the same AR interface that highlights which products need attention and where they are located within the warehouse.

How AR Devices Are Enhancing Inventory Accuracy

One of the most significant advantages of using AR devices in inventory management is the enhancement of accuracy in stock counts and data entry. Traditional methods often lead to discrepancies due to human error during manual counting or data input. However, AR technology mitigates these risks by providing visual confirmations and prompts that guide users through the inventory process.

For instance, when scanning items for restocking or shipping, AR devices can display visual indicators that confirm whether the correct item is being handled, thereby reducing the likelihood of mispicks. Additionally, AR devices can integrate with barcode scanning technology to automate data capture.

This immediate feedback loop not only enhances accuracy but also allows for more efficient inventory audits. Companies can conduct cycle counts more frequently and with greater confidence, knowing that their data is up-to-date and reliable. As a result, businesses can maintain optimal stock levels and reduce instances of stockouts or overstock situations.

The Impact of AR Devices on Inventory Replenishment

The impact of AR devices on inventory replenishment processes is profound, as they enable organizations to respond more swiftly to changing demand patterns. With real-time visibility into stock levels and sales trends, businesses can make informed decisions about when and how much inventory to reorder. AR technology can provide alerts when stock levels fall below predefined thresholds, prompting timely replenishment actions that prevent disruptions in supply chains.

For example, a retail store using AR devices can receive notifications on low-selling items that need restocking or high-demand products that require immediate attention. Furthermore, AR devices can assist in optimizing order quantities by analyzing historical sales data and predicting future demand. By overlaying this analytical information onto the physical inventory space, employees can make better decisions regarding which items to prioritize for replenishment.

This proactive approach not only enhances customer satisfaction by ensuring product availability but also minimizes excess inventory costs associated with overstocking. As businesses increasingly adopt data-driven strategies, the role of AR in facilitating smarter replenishment practices will continue to grow.

Utilizing AR Devices for Inventory Visualization and Organization

| Metric | Before AR Implementation | After AR Implementation | Improvement |

|---|---|---|---|

| Inventory Counting Time | 8 hours per cycle | 3 hours per cycle | 62.5% reduction |

| Picking Accuracy | 92% | 98.5% | 6.5% increase |

| Training Time for New Employees | 5 days | 2 days | 60% reduction |

| Order Fulfillment Speed | 24 hours | 16 hours | 33.3% faster |

| Error Rate in Inventory Data | 7% | 1.5% | 78.6% reduction |

| Employee Productivity (Items Picked per Hour) | 50 items/hour | 80 items/hour | 60% increase |

AR devices excel at enhancing inventory visualization and organization by transforming how employees interact with their surroundings. In a warehouse or retail environment, cluttered aisles and disorganized shelves can lead to inefficiencies and lost productivity. However, with AR technology, employees can visualize optimal storage layouts and item placements directly through their devices.

For instance, an employee wearing AR glasses may see a digital overlay indicating where each product should be stored based on its sales velocity or size, allowing for more efficient use of space. Moreover, AR can assist in creating dynamic visualizations that adapt to changing inventory conditions. As items are added or removed from stock, the AR system can update its visual cues accordingly, ensuring that employees always have access to accurate information about product locations and quantities.

This capability not only streamlines picking processes but also enhances overall organization within the facility. By reducing the time spent searching for items or navigating through cluttered spaces, businesses can significantly improve their operational efficiency.

The Integration of AR Devices with Inventory Management Systems

The successful implementation of AR devices in inventory management hinges on their integration with existing inventory management systems (IMS). This integration allows for seamless data exchange between the physical and digital realms, enabling organizations to leverage the full potential of both technologies.

This level of automation reduces administrative burdens and minimizes errors associated with data entry. Furthermore, integrating AR devices with IMS enables businesses to harness advanced analytics capabilities. By collecting data on employee interactions with inventory through AR interfaces, organizations can gain insights into workflow efficiencies and identify areas for improvement.

For example, analytics may reveal that certain products consistently take longer to locate or restock than others, prompting a reevaluation of storage practices or employee training programs. This data-driven approach empowers businesses to continuously refine their inventory management processes and adapt to evolving market demands.

Overcoming Challenges and Limitations of AR Devices in Inventory Management

Despite the numerous benefits associated with AR devices in inventory management, several challenges and limitations must be addressed for successful implementation. One significant hurdle is the initial investment required for acquiring AR hardware and software solutions. While prices have decreased over time, organizations may still face budget constraints that limit their ability to adopt this technology fully.

Additionally, training employees to effectively use AR devices can be time-consuming and may require ongoing support as technology evolves. Another challenge lies in ensuring compatibility between AR devices and existing inventory management systems. Organizations may encounter difficulties integrating new technologies with legacy systems that were not designed to accommodate such innovations.

This lack of interoperability can hinder the effectiveness of AR solutions and lead to frustration among employees who rely on these tools for their daily tasks. To overcome these challenges, businesses must carefully evaluate their technological infrastructure and invest in training programs that empower employees to embrace new tools confidently.

The Future of AR Devices in Revolutionizing Inventory Management

Looking ahead, the future of AR devices in inventory management appears promising as technology continues to advance at an unprecedented pace. Emerging trends such as artificial intelligence (AI) integration with AR systems are likely to enhance decision-making capabilities further. For instance, AI algorithms could analyze vast amounts of historical sales data alongside real-time inventory information to provide predictive insights that guide replenishment strategies more effectively than ever before.

Moreover, as 5G technology becomes more widespread, the potential for real-time data transmission will significantly enhance the functionality of AR devices in inventory management settings. With faster connectivity speeds and reduced latency, employees will be able to access critical information instantaneously while navigating through warehouses or retail spaces. This capability will not only improve operational efficiency but also enable organizations to respond more agilely to market fluctuations.

In conclusion, as businesses continue to explore innovative solutions for optimizing their inventory management processes, the role of AR devices will undoubtedly expand. By enhancing tracking accuracy, streamlining replenishment practices, and improving overall organization within facilities, these technologies are poised to revolutionize how companies manage their inventories in an increasingly complex supply chain landscape. As organizations embrace this technological shift, they will be better equipped to meet customer demands while maintaining operational excellence.

In the realm of inventory management, augmented reality (AR) devices are revolutionizing efficiency by providing real-time data and enhancing visualizations. For a deeper understanding of how technology is shaping our daily lives, you might find the article on the Google Pixel phone particularly interesting, as it explores the unique features that set this device apart, showcasing how advanced technology can streamline various tasks, including inventory management.

FAQs

What are AR devices?

AR devices, or Augmented Reality devices, are wearable or handheld technologies that overlay digital information onto the real-world environment, enhancing the user’s perception and interaction with their surroundings.

How do AR devices improve inventory management?

AR devices improve inventory management by providing real-time data visualization, hands-free access to inventory information, streamlined picking and packing processes, and enhanced accuracy in locating and tracking items.

What types of AR devices are commonly used in inventory management?

Common AR devices used in inventory management include smart glasses, head-mounted displays, and handheld AR scanners, which enable workers to view digital instructions and inventory data while performing tasks.

Can AR devices reduce errors in inventory management?

Yes, AR devices help reduce errors by providing precise, real-time information and guidance, minimizing manual data entry mistakes and improving the accuracy of stock counts and order fulfillment.

Do AR devices increase productivity in warehouses?

AR devices increase productivity by enabling faster navigation through warehouses, optimizing picking routes, and allowing workers to perform tasks hands-free, which speeds up inventory processes.

Are AR devices cost-effective for inventory management?

While initial investment in AR technology can be significant, the long-term benefits such as reduced errors, improved efficiency, and faster training often result in cost savings and a positive return on investment.

Is training required to use AR devices for inventory management?

Yes, some training is typically required to familiarize employees with AR device operation and software interfaces, but many systems are designed to be user-friendly and intuitive.

Can AR devices integrate with existing inventory management systems?

Most AR devices can integrate with existing warehouse management systems (WMS) and enterprise resource planning (ERP) software to provide seamless data synchronization and enhanced operational workflows.

Are AR devices suitable for all types of inventory environments?

AR devices are versatile and can be adapted to various inventory environments, including warehouses, retail stores, and manufacturing facilities, though the specific device and software may vary based on operational needs.

What future developments are expected in AR for inventory management?

Future developments may include more advanced AI integration, improved device ergonomics, enhanced data analytics, and greater automation capabilities to further streamline inventory management processes.