The pharmaceutical industry is undergoing a transformative shift, driven by the integration of artificial intelligence (AI) and robotics into manufacturing processes. This convergence of technologies is not merely a trend; it represents a fundamental change in how drugs are produced, tested, and delivered to patients. AI-powered robotics combines the precision and efficiency of robotic systems with the analytical capabilities of AI, enabling manufacturers to optimize production lines, enhance quality control, and reduce operational costs.

As the demand for pharmaceuticals continues to rise, fueled by an aging population and increasing prevalence of chronic diseases, the need for innovative manufacturing solutions becomes ever more critical. AI-powered robotics in pharmaceutical manufacturing encompasses a wide range of applications, from automating repetitive tasks to sophisticated data analysis that informs decision-making. These technologies can streamline processes such as drug formulation, packaging, and distribution, while also ensuring compliance with stringent regulatory standards.

The integration of AI allows for real-time monitoring and predictive analytics, which can significantly enhance the agility and responsiveness of manufacturing operations. As pharmaceutical companies strive to meet the challenges posed by global health crises and rapidly changing market dynamics, the adoption of AI-powered robotics emerges as a strategic imperative.

Key Takeaways

- AI-powered robotics in pharmaceutical manufacturing combines artificial intelligence with robotic technology to improve efficiency and accuracy in the production process.

- Advantages of AI-powered robotics in pharmaceutical manufacturing include increased productivity, reduced errors, improved quality control, and enhanced safety for workers.

- Applications of AI-powered robotics in pharmaceutical manufacturing range from drug discovery and development to packaging and labeling, as well as quality control and inspection.

- Challenges and limitations of AI-powered robotics in pharmaceutical manufacturing include high initial investment costs, potential job displacement, and the need for ongoing maintenance and updates.

- Integration of AI-powered robotics with existing manufacturing processes requires careful planning, training, and collaboration between human workers and automated systems to ensure seamless operation and maximum benefits.

Advantages of AI-Powered Robotics in Pharmaceutical Manufacturing

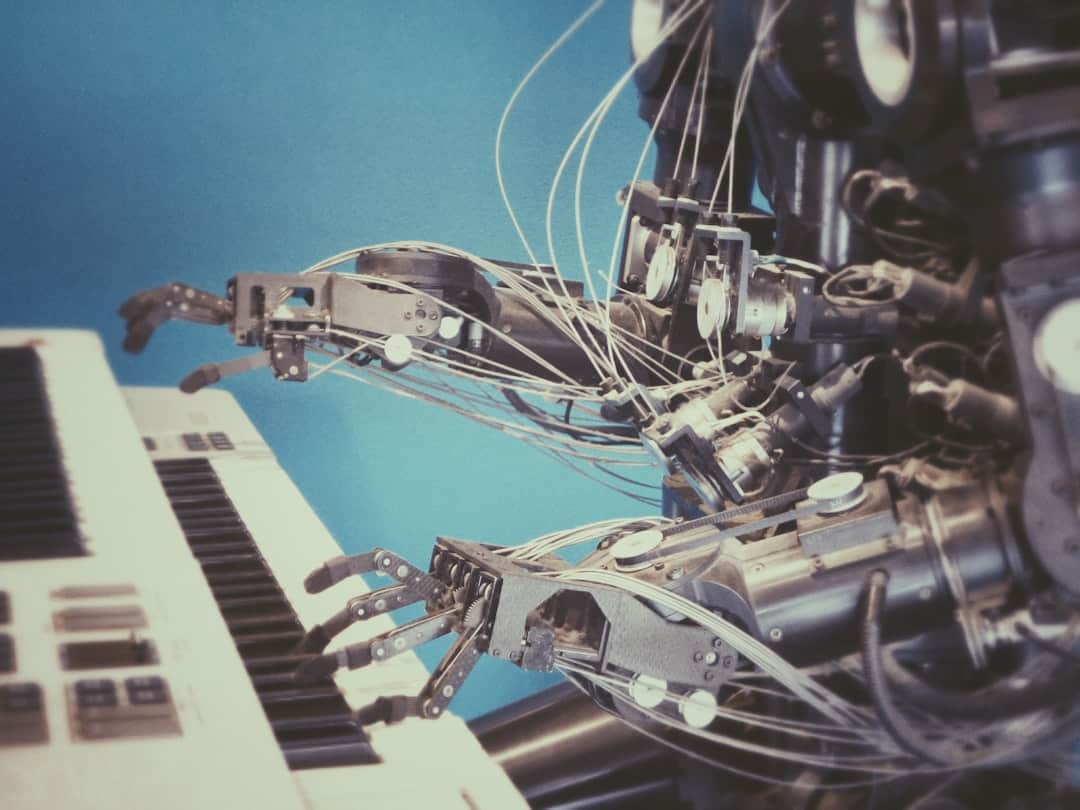

One of the most significant advantages of AI-powered robotics in pharmaceutical manufacturing is the enhancement of operational efficiency. Traditional manufacturing processes often involve manual labor, which can be time-consuming and prone to human error. By automating these tasks with robotics, companies can achieve higher throughput rates and reduce production times.

For instance, robotic systems can handle repetitive tasks such as filling vials or labeling packages with remarkable speed and accuracy, minimizing the risk of contamination or mislabeling that could lead to costly recalls. Moreover, AI algorithms can analyze vast amounts of data generated during the manufacturing process to identify inefficiencies and optimize workflows. This data-driven approach enables manufacturers to make informed decisions about resource allocation, equipment maintenance, and process improvements.

For example, predictive maintenance powered by AI can forecast equipment failures before they occur, allowing for timely interventions that prevent costly downtime. The result is a more streamlined operation that not only saves time but also reduces waste and lowers production costs.

Applications of AI-Powered Robotics in Pharmaceutical Manufacturing

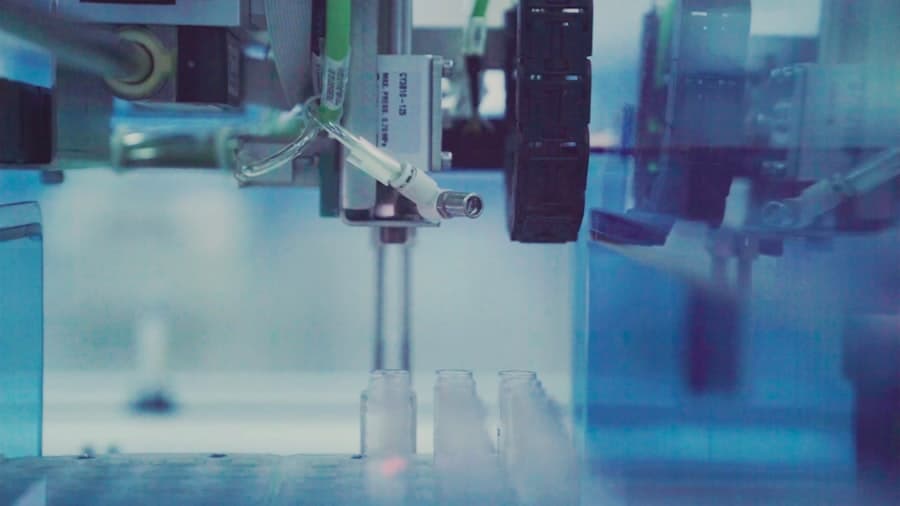

The applications of AI-powered robotics in pharmaceutical manufacturing are diverse and impactful. One prominent area is in drug formulation, where robotic systems equipped with AI can assist in the precise mixing of ingredients to create formulations that meet specific therapeutic requirements. These systems can adjust parameters in real-time based on feedback from sensors monitoring the mixing process, ensuring consistency and quality in the final product.

Another critical application is in quality control and assurance. AI-powered vision systems can inspect products at various stages of production, identifying defects or deviations from specifications with a level of accuracy that surpasses human inspectors. For instance, these systems can detect minute particles or inconsistencies in packaging that could compromise product integrity.

Additionally, AI can analyze historical quality data to predict potential quality issues before they arise, allowing manufacturers to implement corrective actions proactively. Robotics also plays a vital role in logistics and supply chain management within pharmaceutical manufacturing. Automated guided vehicles (AGVs) can transport materials between different areas of a facility, optimizing workflow and reducing the risk of contamination during manual handling.

Furthermore, AI algorithms can enhance inventory management by predicting demand patterns and optimizing stock levels, ensuring that production lines are never halted due to material shortages.

Challenges and Limitations of AI-Powered Robotics in Pharmaceutical Manufacturing

Despite the numerous advantages offered by AI-powered robotics, several challenges and limitations must be addressed for successful implementation in pharmaceutical manufacturing. One significant hurdle is the high initial investment required for advanced robotic systems and AI technologies. Many pharmaceutical companies operate on tight margins, making it difficult to justify the upfront costs associated with upgrading existing infrastructure or integrating new technologies.

Additionally, there is a steep learning curve associated with deploying AI-powered robotics. Employees must be trained not only to operate these advanced systems but also to understand the underlying AI algorithms that drive decision-making processes. This necessitates a cultural shift within organizations, as staff must adapt to new roles that focus on oversight and collaboration with machines rather than traditional manual tasks.

Resistance to change can hinder the adoption of these technologies, particularly in organizations with established practices. Another challenge lies in data management and cybersecurity. The integration of AI into manufacturing processes generates vast amounts of data that must be stored, analyzed, and protected.

Ensuring data integrity and security is paramount, especially given the sensitive nature of pharmaceutical products and patient information. Companies must invest in robust cybersecurity measures to safeguard against potential breaches that could compromise both operational efficiency and regulatory compliance.

Integration of AI-Powered Robotics with Existing Manufacturing Processes

Integrating AI-powered robotics into existing pharmaceutical manufacturing processes requires careful planning and execution. A phased approach is often recommended, allowing companies to gradually introduce automation while minimizing disruption to ongoing operations. This may involve piloting specific applications before scaling up across the entire production line.

For example, a company might start by automating a single task—such as packaging—before expanding automation efforts to other areas like quality control or inventory management. Collaboration between IT and operational teams is crucial during this integration process. IT professionals must ensure that the necessary infrastructure is in place to support AI algorithms and robotic systems, including data storage solutions and network capabilities.

Meanwhile, operational teams must provide insights into existing workflows and identify areas where automation can deliver the most significant benefits. This cross-functional collaboration fosters a holistic understanding of how AI-powered robotics can enhance overall productivity while maintaining compliance with industry regulations. Moreover, integrating these technologies requires a focus on interoperability.

Many pharmaceutical manufacturers utilize legacy systems that may not be compatible with modern AI solutions. To address this challenge, companies may need to invest in middleware or custom software solutions that facilitate communication between disparate systems. Ensuring seamless integration not only enhances operational efficiency but also allows for better data sharing across departments, leading to more informed decision-making.

Future Trends in AI-Powered Robotics for Pharmaceutical Manufacturing

As technology continues to evolve, several trends are emerging that will shape the future of AI-powered robotics in pharmaceutical manufacturing. One notable trend is the increasing use of collaborative robots, or cobots, which are designed to work alongside human operators rather than replace them. These robots can assist with tasks that require precision while allowing human workers to focus on more complex responsibilities that require critical thinking and problem-solving skills.

Another trend is the growing emphasis on personalized medicine, which necessitates more flexible manufacturing processes capable of producing small batches tailored to individual patient needs. AI-powered robotics can facilitate this shift by enabling rapid reconfiguration of production lines to accommodate varying product specifications without significant downtime. This adaptability will be essential as pharmaceutical companies strive to meet the demands of personalized therapies while maintaining efficiency.

Furthermore, advancements in machine learning algorithms will enhance the capabilities of AI-powered robotics in predictive analytics and decision-making. As these algorithms become more sophisticated, they will enable manufacturers to anticipate market trends, optimize supply chains dynamically, and improve overall operational resilience. The ability to leverage real-time data for strategic decision-making will be a game-changer for pharmaceutical manufacturers navigating an increasingly complex landscape.

Regulatory Considerations for AI-Powered Robotics in Pharmaceutical Manufacturing

The integration of AI-powered robotics into pharmaceutical manufacturing raises important regulatory considerations that must be addressed to ensure compliance with industry standards. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) have established guidelines governing the use of automation and AI in drug production processes.

Manufacturers must navigate these regulations carefully to avoid potential pitfalls that could lead to delays in product approval or costly fines. One key regulatory consideration is validation. Pharmaceutical manufacturers are required to validate their processes to ensure consistent product quality and safety.

When implementing AI-powered robotics, companies must demonstrate that these systems perform reliably under various conditions and produce outputs that meet established specifications. This validation process can be complex and time-consuming, requiring extensive documentation and testing. Additionally, manufacturers must consider data integrity when utilizing AI technologies.

Regulatory agencies expect companies to maintain accurate records throughout the manufacturing process, including data generated by robotic systems and AI algorithms. Implementing robust data management practices is essential for ensuring compliance with regulations such as 21 CFR Part 11 in the United States, which outlines requirements for electronic records and signatures.

Case Studies of Successful Implementation of AI-Powered Robotics in Pharmaceutical Manufacturing

Several pharmaceutical companies have successfully implemented AI-powered robotics into their manufacturing processes, showcasing the potential benefits of this technology. One notable example is Amgen’s use of robotic systems for drug formulation and packaging at its facility in Rhode Island. By integrating advanced robotics into its production line, Amgen has achieved significant improvements in efficiency while maintaining stringent quality standards.

The company reported a reduction in cycle times by over 30%, allowing it to respond more rapidly to market demands. Another compelling case study comes from Novartis, which has embraced AI-driven automation at its production site in Switzerland. The company implemented an intelligent robotic system capable of performing multiple tasks across different stages of production—from material handling to quality inspection—without requiring extensive reprogramming between batches.

This flexibility has enabled Novartis to produce a wider range of products while minimizing downtime associated with changeovers. These case studies illustrate not only the operational advantages gained through the adoption of AI-powered robotics but also highlight the potential for enhanced product quality and regulatory compliance. As more pharmaceutical manufacturers explore these technologies, it becomes increasingly clear that AI-powered robotics will play a pivotal role in shaping the future landscape of drug production.

If you are interested in exploring the intersection of technology and innovation in various industries, you may also enjoy reading about the best laptops for Blender in 2023. This article provides top picks and reviews for laptops that are ideal for running Blender, a popular 3D modeling software. Check it out here.

FAQs

What is AI-powered robotics in pharmaceutical manufacturing?

AI-powered robotics in pharmaceutical manufacturing refers to the use of advanced robotics technology that is integrated with artificial intelligence (AI) to automate and streamline various processes in the pharmaceutical production line. This technology can perform tasks such as drug discovery, quality control, packaging, and logistics with greater efficiency and accuracy.

How does AI-powered robotics simplify pharmaceutical manufacturing?

AI-powered robotics simplifies pharmaceutical manufacturing by automating repetitive and labor-intensive tasks, reducing human error, and increasing overall efficiency. This technology can also analyze large volumes of data to optimize production processes, improve quality control, and accelerate drug development timelines.

What are the benefits of using AI-powered robotics in pharmaceutical manufacturing?

Some of the benefits of using AI-powered robotics in pharmaceutical manufacturing include increased productivity, improved product quality, reduced production costs, enhanced safety for workers, and the ability to adapt to changing production demands. Additionally, AI-powered robotics can help pharmaceutical companies bring new drugs to market faster and more efficiently.

Are there any challenges or limitations associated with AI-powered robotics in pharmaceutical manufacturing?

While AI-powered robotics offers numerous advantages, there are also challenges and limitations to consider. These may include the initial investment required for implementing the technology, the need for specialized training for personnel, potential job displacement for certain roles, and the ongoing need to ensure regulatory compliance and cybersecurity measures. Additionally, integrating AI-powered robotics into existing manufacturing processes may require careful planning and coordination.