The advent of artificial intelligence (AI) has revolutionized various sectors, and manufacturing is no exception.

These factories leverage AI to enhance operational efficiency, reduce costs, and improve product quality.

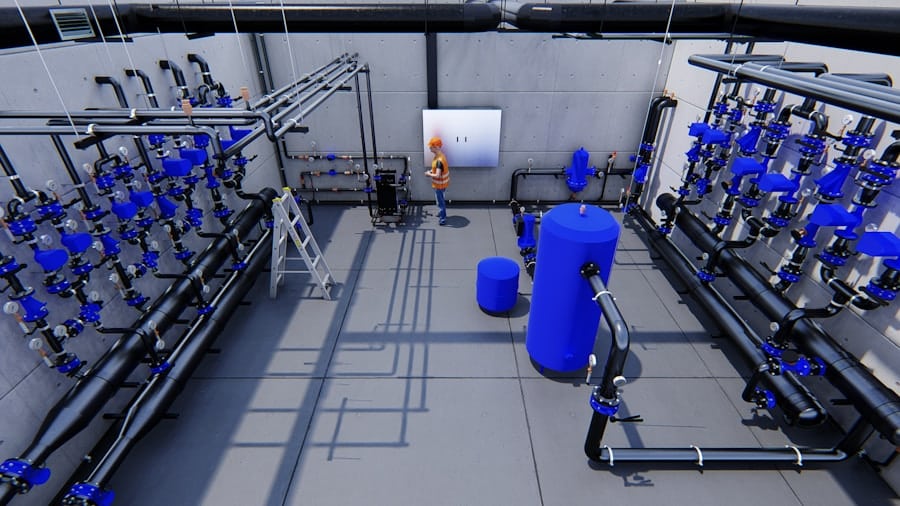

By harnessing vast amounts of data generated from machines and processes, AI algorithms can identify patterns, predict outcomes, and facilitate decision-making in real time. In smart factory operations, AI serves as the backbone for achieving a high level of automation and connectivity. The integration of AI technologies enables machines to communicate with each other and with human operators, creating a seamless flow of information.

This interconnectedness allows for more agile responses to changes in production demands and market conditions. As industries strive for greater competitiveness, the implementation of AI in smart factories is not merely an option but a necessity for staying relevant in an increasingly digital landscape.

Key Takeaways

- AI plays a crucial role in optimizing smart factory operations by enabling real-time monitoring, predictive maintenance, quality control, inventory management, energy efficiency, workforce management, and adaptive production planning.

- Real-time monitoring and predictive maintenance powered by AI help in identifying and addressing equipment issues before they lead to costly downtime, ensuring smooth and uninterrupted operations.

- AI-driven quality control and defect detection systems enhance product quality and reduce waste by identifying and addressing defects in real-time, leading to improved customer satisfaction and cost savings.

- AI-based inventory management and supply chain optimization systems help in minimizing stockouts, reducing excess inventory, and optimizing supply chain processes, leading to improved efficiency and cost savings.

- AI enables smart factories to optimize energy usage and resource utilization, leading to reduced operational costs and environmental impact, while also ensuring a sustainable and efficient production process.

Real-Time Monitoring and Predictive Maintenance

One of the most significant applications of AI in smart factories is real-time monitoring and predictive maintenance. Traditional maintenance practices often rely on scheduled inspections or reactive measures after equipment failure occurs. However, these methods can lead to unplanned downtime and increased operational costs.

AI-driven predictive maintenance shifts the focus from reactive to proactive strategies by utilizing machine learning algorithms to analyze data from sensors embedded in machinery. This analysis helps predict when a machine is likely to fail, allowing for timely interventions that minimize disruptions. For instance, a manufacturing plant producing automotive components may implement AI systems that continuously monitor the performance of critical machinery.

By analyzing vibration patterns, temperature fluctuations, and operational metrics, the AI can identify anomalies that indicate potential failures. This predictive capability enables maintenance teams to address issues before they escalate into costly breakdowns. As a result, manufacturers can optimize their maintenance schedules, reduce downtime, and extend the lifespan of their equipment.

Quality Control and Defect Detection

Quality control is paramount in manufacturing, where even minor defects can lead to significant financial losses and damage to brand reputation. AI enhances quality control processes through advanced defect detection techniques that surpass traditional methods. Machine vision systems powered by AI can inspect products at high speeds with remarkable accuracy.

These systems utilize deep learning algorithms trained on vast datasets of images to recognize defects that may be invisible to the human eye. For example, in the electronics manufacturing sector, AI-driven visual inspection systems can detect minute defects on circuit boards during production. By analyzing images captured by high-resolution cameras, these systems can identify issues such as soldering defects or component misalignments in real time.

The ability to catch defects early in the production process not only reduces waste but also ensures that only high-quality products reach customers. This level of precision contributes to enhanced customer satisfaction and loyalty.

Inventory Management and Supply Chain Optimization

Efficient inventory management is crucial for maintaining production flow and minimizing costs in smart factories. AI plays a pivotal role in optimizing inventory levels by analyzing historical data, market trends, and demand forecasts. Machine learning algorithms can predict fluctuations in demand with remarkable accuracy, allowing manufacturers to adjust their inventory accordingly.

This dynamic approach helps prevent overstocking or stockouts, both of which can disrupt production schedules. In addition to inventory management, AI enhances supply chain optimization by providing insights into supplier performance and logistics efficiency. For instance, a manufacturer may use AI to analyze data from various suppliers regarding delivery times, quality metrics, and pricing trends.

By evaluating this information, the manufacturer can make informed decisions about which suppliers to prioritize or negotiate with for better terms. Furthermore, AI can optimize transportation routes based on real-time traffic data and weather conditions, ensuring timely deliveries while minimizing transportation costs.

Energy Efficiency and Resource Utilization

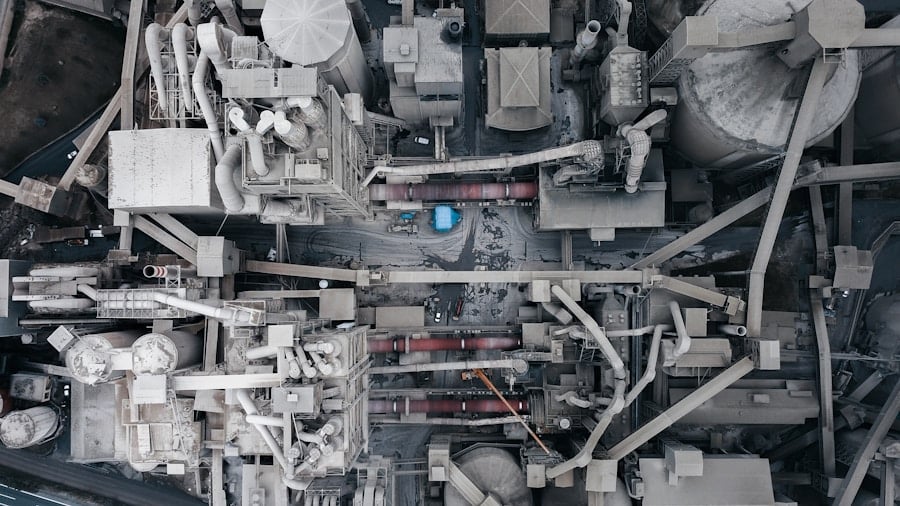

Energy consumption is a significant concern for manufacturers seeking to reduce operational costs and minimize their environmental impact. AI technologies contribute to energy efficiency by analyzing energy usage patterns and identifying opportunities for optimization. Smart factories equipped with AI can monitor energy consumption across various processes and machinery, enabling manufacturers to pinpoint inefficiencies.

For example, an AI system may analyze energy usage data from different production lines and identify that one line consumes significantly more energy than others due to outdated machinery or inefficient processes. Armed with this information, manufacturers can take corrective actions such as upgrading equipment or implementing energy-saving practices. Additionally, AI can facilitate demand response strategies by adjusting production schedules based on energy pricing fluctuations during peak hours, further enhancing resource utilization.

Workforce Management and Safety

Enhancing Workplace Safety

Safety is a paramount concern in manufacturing environments where heavy machinery operates. AI technologies contribute to workplace safety by monitoring conditions in real time and identifying potential hazards. For instance, computer vision systems can detect unsafe behaviors or conditions, such as workers not wearing proper safety gear or equipment operating outside safe parameters.

Real-time Hazard Identification

By alerting supervisors or automatically shutting down machinery when unsafe conditions are detected, AI helps create a safer work environment.

Adaptive Production Planning and Scheduling

In an era where consumer preferences are constantly evolving, adaptive production planning and scheduling have become essential for manufacturers aiming to remain competitive. AI enables smart factories to respond swiftly to changes in demand by analyzing real-time data from various sources, including sales forecasts, market trends, and production capabilities. This adaptability allows manufacturers to adjust their production schedules dynamically without compromising efficiency.

For instance, a clothing manufacturer may utilize AI algorithms to analyze sales data from retail partners and social media trends to predict which styles will be in demand next season. Based on these insights, the manufacturer can adjust its production schedule accordingly, prioritizing certain designs while scaling back on others that are projected to be less popular. This level of responsiveness not only minimizes excess inventory but also aligns production closely with market demands.

Future Trends and Implications for Smart Factory Operations

As technology continues to advance at an unprecedented pace, the future of smart factory operations will likely be shaped by several emerging trends driven by AI. One significant trend is the increasing integration of edge computing with AI technologies. By processing data closer to where it is generated—on the factory floor—manufacturers can achieve faster response times and reduce latency in decision-making processes.

Another trend is the growing emphasis on sustainability within manufacturing operations. As environmental concerns become more pressing, manufacturers are turning to AI not only for efficiency gains but also for reducing their carbon footprint. AI can help optimize resource usage and minimize waste throughout the production cycle, aligning with global sustainability goals.

Furthermore, the rise of collaborative robots (cobots) powered by AI will redefine human-machine interactions in smart factories. These robots are designed to work alongside human operators safely and efficiently, enhancing productivity while allowing workers to focus on more complex tasks that require creativity and problem-solving skills. In conclusion, the integration of AI into smart factory operations is not merely a technological upgrade; it represents a fundamental shift in how manufacturing processes are conceived and executed.

As industries continue to embrace these advancements, the potential for increased efficiency, improved quality control, optimized resource utilization, and enhanced workforce management will redefine the landscape of manufacturing for years to come.

If you are interested in learning more about how technology is revolutionizing various industries, you may want to check out this article on Screpy Reviews 2023. This article discusses how a new tool called Screpy is helping businesses improve their online presence and optimize their websites for better performance. Just like AI is optimizing smart factory operations in real time, Screpy is helping companies stay ahead of the curve in the digital world.

FAQs

What is AI in the context of smart factory operations?

AI, or artificial intelligence, refers to the simulation of human intelligence processes by machines, particularly computer systems. In the context of smart factory operations, AI is used to optimize and automate processes, make real-time decisions, and improve overall efficiency.

How is AI being used to optimize smart factory operations in real time?

AI is being used in smart factories to collect and analyze large amounts of data from various sources, such as sensors and machines, in real time. This data is then used to make predictive and prescriptive decisions, optimize production processes, and identify potential issues before they occur.

What are the benefits of using AI to optimize smart factory operations?

Some of the benefits of using AI to optimize smart factory operations include improved efficiency, reduced downtime, predictive maintenance, better resource allocation, and the ability to adapt to changing production demands in real time.

What are some examples of AI applications in smart factory operations?

Some examples of AI applications in smart factory operations include predictive maintenance, quality control, demand forecasting, supply chain optimization, autonomous robots, and real-time production scheduling.

What are the challenges of implementing AI in smart factory operations?

Challenges of implementing AI in smart factory operations include data integration and quality, cybersecurity risks, workforce training, and the initial investment required for AI technology and infrastructure.