The advent of artificial intelligence (AI) has revolutionized numerous industries, and warehousing and logistics are no exceptions. AI-driven robots are increasingly becoming integral components of supply chain operations, enhancing efficiency, accuracy, and productivity. These robots leverage advanced algorithms, machine learning, and real-time data analytics to perform tasks that were traditionally labor-intensive.

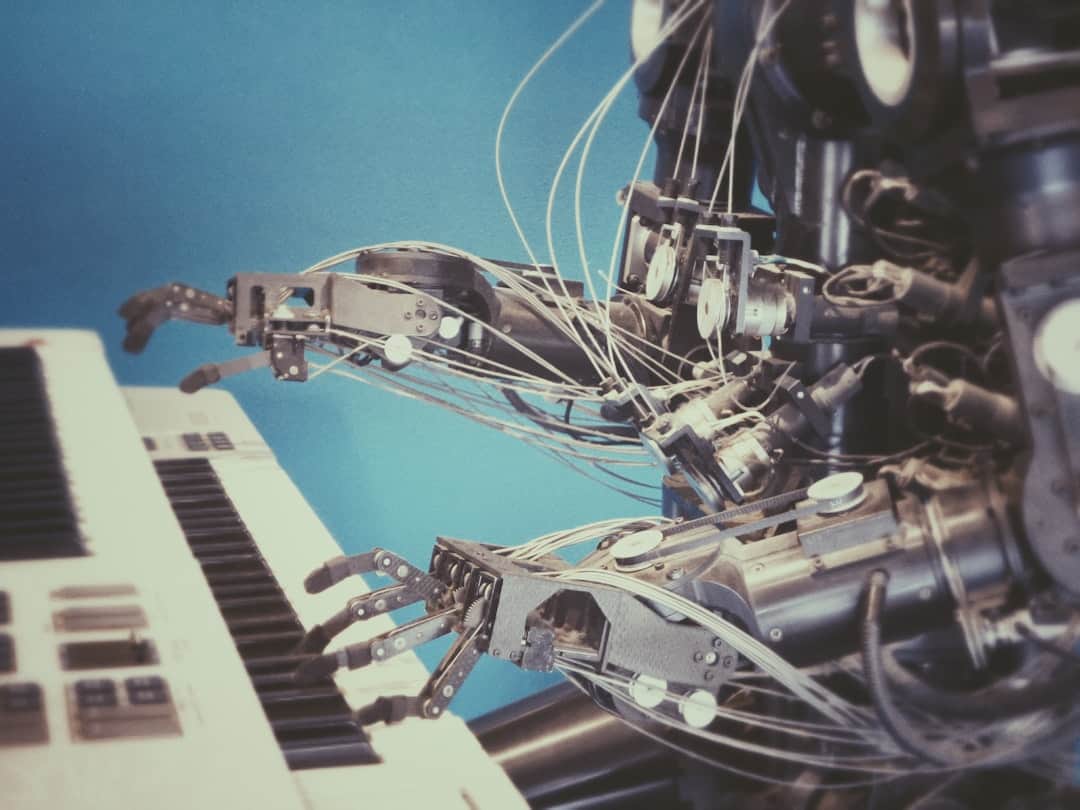

As businesses strive to meet the growing demands of e-commerce and global trade, the integration of AI-driven robots into warehousing and logistics operations is not merely a trend but a necessity. The deployment of AI-driven robots in these sectors is transforming how goods are stored, retrieved, and shipped. From autonomous mobile robots (AMRs) that navigate warehouse floors to robotic arms that handle packaging and sorting, these technologies are designed to optimize workflows and reduce human error.

The ability of AI-driven robots to learn from their environment and adapt to changing conditions allows them to operate efficiently in dynamic settings. As a result, companies are witnessing significant improvements in operational performance, cost savings, and customer satisfaction.

Key Takeaways

- AI-driven robots are revolutionizing warehousing and logistics by improving efficiency and accuracy in inventory management, order fulfillment, and space utilization.

- AI-driven robots play a crucial role in inventory management by automating tasks such as stock counting, tracking, and replenishment, leading to reduced human error and improved inventory accuracy.

- AI-driven robots streamline order fulfillment processes by automating picking, packing, and shipping tasks, resulting in faster and more accurate order processing.

- AI-driven robots improve safety and accuracy in warehousing and logistics by handling repetitive and physically demanding tasks, reducing the risk of injuries and human errors.

- AI-driven robots maximize space utilization in warehouses by efficiently organizing and storing inventory, optimizing storage capacity and reducing the need for additional space.

The Role of AI-Driven Robots in Inventory Management

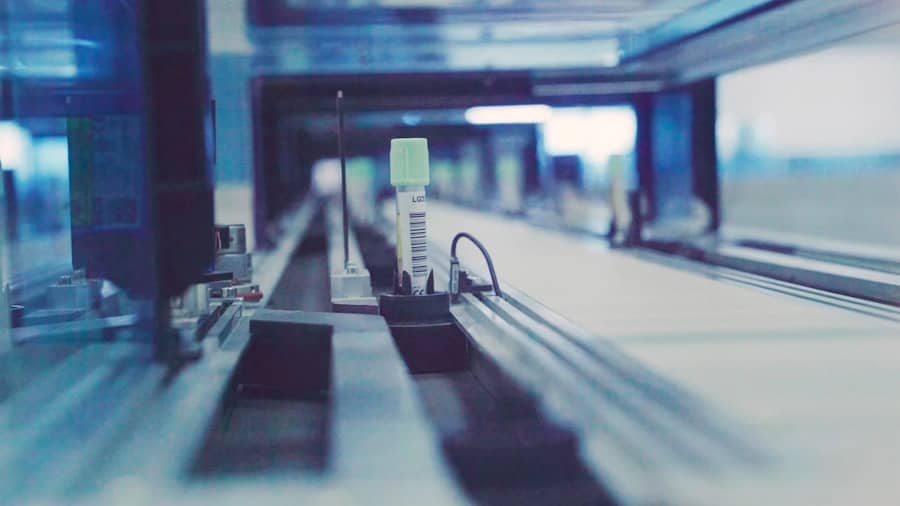

Inventory management is a critical aspect of warehousing that directly impacts a company’s bottom line. AI-driven robots play a pivotal role in this domain by automating the tracking and management of stock levels. Equipped with sophisticated sensors and cameras, these robots can scan barcodes or RFID tags to monitor inventory in real-time.

This capability not only reduces the time spent on manual stock checks but also minimizes the risk of human error, ensuring that inventory records are accurate and up-to-date. Moreover, AI-driven robots can analyze historical data to predict inventory needs based on trends and seasonal fluctuations. For instance, during peak shopping seasons, such as Black Friday or holiday sales, these robots can adjust their operations to accommodate increased demand.

By optimizing stock levels and reducing excess inventory, businesses can improve cash flow and reduce storage costs. The integration of AI in inventory management also facilitates better decision-making, as companies can rely on data-driven insights to inform their purchasing strategies.

How AI-Driven Robots Streamline Order Fulfillment Processes

Order fulfillment is a complex process that involves multiple steps, from picking items off shelves to packing them for shipment. AI-driven robots streamline this process by automating various tasks, thereby reducing the time it takes to fulfill orders. For example, robotic picking systems can identify and retrieve items from shelves with remarkable speed and precision.

These systems utilize computer vision and machine learning algorithms to recognize products and navigate through the warehouse efficiently. In addition to picking, AI-driven robots also enhance packing operations. Automated packing machines can assess the dimensions and weight of items to determine the most efficient packaging solutions.

This not only speeds up the packing process but also reduces material waste by ensuring that the right-sized boxes are used. Furthermore, AI-driven robots can communicate with warehouse management systems to prioritize orders based on delivery deadlines, ensuring that high-priority shipments are processed first. This level of automation leads to faster turnaround times and improved customer satisfaction.

Improving Safety and Accuracy with AI-Driven Robots

Safety is a paramount concern in warehousing environments where heavy machinery and large volumes of goods are handled daily. AI-driven robots contribute significantly to enhancing safety by taking on hazardous tasks that would otherwise pose risks to human workers. For instance, robots can be deployed for repetitive lifting or transporting heavy items across the warehouse floor, reducing the likelihood of workplace injuries related to manual handling.

In addition to improving safety, AI-driven robots also enhance accuracy in operations. The precision with which these robots perform tasks minimizes errors associated with manual processes. For example, when picking items for orders, robotic systems equipped with advanced sensors can ensure that the correct products are selected every time.

This level of accuracy not only reduces returns due to incorrect shipments but also fosters trust between businesses and their customers. As a result, companies can maintain a strong reputation for reliability in their logistics operations.

Maximizing Space Utilization with AI-Driven Robots

Space utilization is a critical factor in warehousing efficiency. With real estate costs rising, businesses are increasingly looking for ways to maximize their storage capacity without expanding their physical footprint. AI-driven robots play a crucial role in optimizing space utilization by enabling more efficient storage solutions.

For instance, autonomous mobile robots can navigate narrow aisles and reach high shelves that may be difficult for human workers to access safely. These robots can also facilitate dynamic storage systems where items are stored based on demand rather than fixed locations. By analyzing data on product turnover rates, AI algorithms can determine the optimal placement of goods within the warehouse.

High-demand items can be stored closer to packing areas for quicker access, while slower-moving products can be placed further away. This strategic organization not only maximizes available space but also enhances overall operational efficiency.

Enhancing Supply Chain Visibility and Transparency with AI-Driven Robots

In today’s fast-paced business environment, supply chain visibility is essential for effective decision-making and risk management. AI-driven robots contribute to this visibility by providing real-time data on inventory levels, order status, and shipment tracking. With integrated sensors and communication systems, these robots can relay information back to centralized management platforms, allowing stakeholders to monitor operations from anywhere.

This enhanced visibility enables companies to respond quickly to disruptions or changes in demand. For example, if a shipment is delayed due to unforeseen circumstances, businesses can adjust their logistics plans accordingly to minimize impact on customers. Additionally, the transparency provided by AI-driven robots fosters collaboration among supply chain partners.

When all parties have access to accurate data, they can work together more effectively to optimize processes and improve overall performance.

The Future of AI-Driven Robots in Warehousing and Logistics

The future of AI-driven robots in warehousing and logistics is poised for significant advancements as technology continues to evolve. Emerging trends such as collaborative robotics—where humans and robots work side by side—are expected to gain traction in warehouses. These collaborative robots (cobots) can assist human workers with physically demanding tasks while allowing them to focus on more complex activities that require critical thinking and problem-solving skills.

Furthermore, advancements in machine learning algorithms will enable robots to become even more autonomous over time. As they gather more data from their environments, they will be able to make informed decisions without human intervention. This could lead to fully automated warehouses where AI-driven robots manage all aspects of operations—from inventory management to order fulfillment—resulting in unprecedented levels of efficiency and productivity.

Case Studies: Successful Implementation of AI-Driven Robots in Warehousing and Logistics

Several companies have successfully implemented AI-driven robots in their warehousing and logistics operations, showcasing the transformative potential of this technology. One notable example is Amazon, which has integrated thousands of Kiva robots into its fulfillment centers. These autonomous mobile robots transport shelves filled with products directly to human workers for picking, significantly reducing the time required for order fulfillment while increasing overall throughput.

Another case study involves Walmart’s use of robotic systems for inventory management. The retail giant has deployed shelf-scanning robots that autonomously navigate store aisles to monitor stock levels and identify misplaced items. This initiative has not only improved inventory accuracy but has also freed up employees to focus on customer service rather than manual stock checks.

These examples illustrate how AI-driven robots are reshaping the landscape of warehousing and logistics by enhancing efficiency, accuracy, and safety while providing valuable insights into operational performance. As more companies recognize the benefits of automation through AI technologies, the adoption of these systems is likely to accelerate across the industry.

A related article to How AI-Driven Robots Improve Efficiency in Warehousing and Logistics is Best Software to Clone HDD to SSD. This article discusses the importance of using the right software to efficiently transfer data from a hard disk drive to a solid-state drive. Just like how AI-driven robots are revolutionizing the warehousing and logistics industry, having the best software for cloning HDD to SSD can greatly improve the speed and accuracy of data transfer processes. Both articles highlight the significance of leveraging technology to enhance efficiency in different sectors.

FAQs

What are AI-driven robots in warehousing and logistics?

AI-driven robots in warehousing and logistics are robotic systems equipped with artificial intelligence technology to perform tasks such as picking, packing, sorting, and transporting goods in a warehouse or distribution center. These robots are designed to work alongside human workers to improve efficiency and productivity in the supply chain.

How do AI-driven robots improve efficiency in warehousing and logistics?

AI-driven robots improve efficiency in warehousing and logistics by automating repetitive and time-consuming tasks, reducing errors, and increasing the speed and accuracy of order fulfillment. These robots can also optimize warehouse layout and inventory management, leading to cost savings and improved operational performance.

What are the benefits of using AI-driven robots in warehousing and logistics?

Some of the benefits of using AI-driven robots in warehousing and logistics include increased productivity, reduced labor costs, improved order accuracy, faster order fulfillment, enhanced safety for workers, and the ability to adapt to changing demand and seasonal fluctuations in the supply chain.

What types of AI-driven robots are commonly used in warehousing and logistics?

Common types of AI-driven robots used in warehousing and logistics include autonomous mobile robots (AMRs) for material handling, robotic arms for picking and packing, automated guided vehicles (AGVs) for transportation, and drones for inventory management and surveillance. These robots are equipped with sensors, cameras, and AI algorithms to navigate and perform tasks in a warehouse environment.

What are the challenges of implementing AI-driven robots in warehousing and logistics?

Challenges of implementing AI-driven robots in warehousing and logistics include the initial investment cost, integration with existing warehouse systems, training and re-skilling of workers, maintenance and technical support, as well as regulatory and safety considerations. However, the potential benefits of using AI-driven robots often outweigh these challenges in the long run.