The advent of artificial intelligence (AI) has revolutionized numerous sectors, with manufacturing being one of the most significantly impacted. AI-driven robots are at the forefront of this transformation, integrating advanced algorithms and machine learning capabilities to enhance operational efficiency and productivity. These robots are not merely programmed machines; they possess the ability to learn from their environment, adapt to new tasks, and make decisions based on real-time data.

This evolution marks a departure from traditional automation, which relied heavily on fixed programming and repetitive tasks. In the context of assembly lines, AI-driven robots are reshaping how products are manufactured. They can perform complex tasks that require precision and adaptability, such as assembling intricate components or adjusting to variations in product design.

The integration of AI allows these robots to analyze vast amounts of data, optimizing their performance and improving overall workflow. As industries strive for greater efficiency and flexibility, the role of AI-driven robots becomes increasingly critical, paving the way for smarter manufacturing processes that can respond dynamically to market demands.

Key Takeaways

- AI-driven robots are revolutionizing the manufacturing industry by increasing efficiency and flexibility in assembly lines.

- AI has a significant impact on assembly line flexibility, allowing for quick reconfiguration and adaptation to changing production needs.

- The advantages of using AI-driven robots in assembly lines include increased productivity, improved quality control, and reduced operational costs.

- Challenges and limitations of AI-driven robots in assembly lines include high initial investment, potential job displacement, and the need for continuous maintenance and updates.

- Case studies of successful implementation of AI-driven robots demonstrate their ability to streamline production, enhance safety, and meet increasing consumer demands.

The Impact of AI on Assembly Line Flexibility

AI has fundamentally altered the landscape of assembly line operations by introducing a level of flexibility that was previously unattainable. Traditional assembly lines were characterized by rigid processes that could not easily accommodate changes in product design or production volume. However, with the introduction of AI-driven robots, manufacturers can now adapt their assembly lines to meet fluctuating demands without significant downtime or reconfiguration costs.

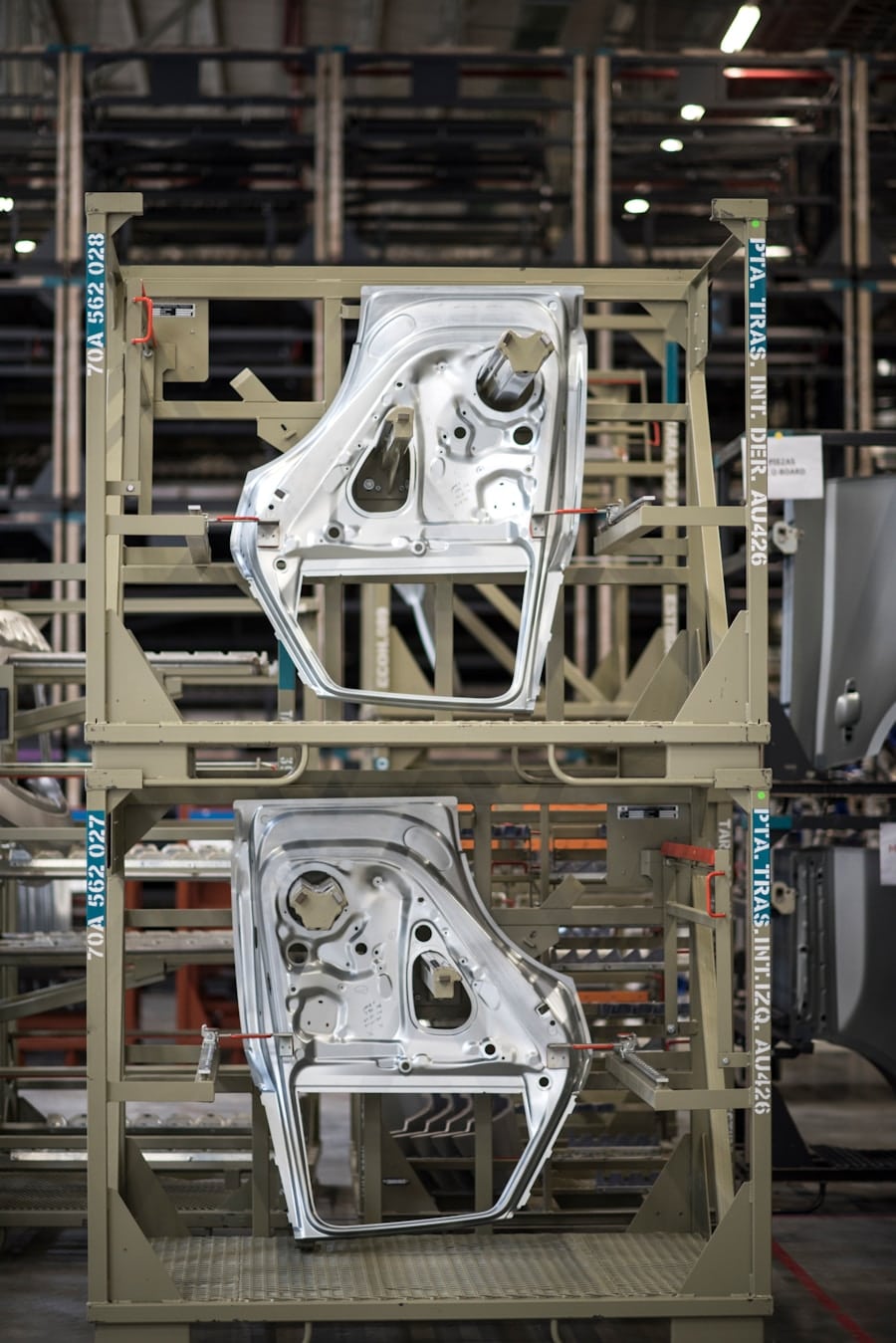

These robots can be reprogrammed or trained to handle different tasks, allowing for rapid shifts in production focus. For instance, in the automotive industry, manufacturers often face varying consumer preferences and regulatory requirements that necessitate quick changes in vehicle design. AI-driven robots can seamlessly transition from assembling one model to another, adjusting their operations based on real-time data inputs.

This adaptability not only enhances production efficiency but also reduces waste and lowers costs associated with overproduction or underutilization of resources. The ability to pivot quickly in response to market trends is a game-changer for companies striving to maintain a competitive edge.

Advantages of Using AI-Driven Robots in Assembly Lines

The advantages of incorporating AI-driven robots into assembly lines are manifold, extending beyond mere operational efficiency. One of the most significant benefits is the enhancement of precision and quality control. AI algorithms can analyze data from sensors embedded in robots to detect anomalies or deviations from standard operating procedures.

This capability allows for immediate corrective actions, reducing defects and ensuring that products meet stringent quality standards. Moreover, AI-driven robots can operate continuously without fatigue, unlike human workers who may experience declines in performance over time due to exhaustion or monotony. This continuous operation capability leads to increased throughput and reduced cycle times, enabling manufacturers to meet tight deadlines and respond swiftly to customer demands.

Additionally, the integration of AI can lead to improved safety on the assembly line.

Challenges and Limitations of AI-Driven Robots in Assembly Lines

Despite the numerous advantages, the implementation of AI-driven robots in assembly lines is not without its challenges and limitations. One significant hurdle is the initial investment required for integrating advanced robotics and AI technologies into existing manufacturing systems. The costs associated with purchasing sophisticated robots, upgrading infrastructure, and training personnel can be substantial, particularly for small and medium-sized enterprises (SMEs) that may lack the financial resources to make such investments.

Furthermore, there are technical challenges related to the integration of AI systems with legacy equipment. Many manufacturing facilities still rely on older machinery that may not be compatible with modern AI technologies. This incompatibility can lead to disruptions during the transition phase as companies work to ensure that new systems can communicate effectively with existing processes.

Additionally, there is a learning curve associated with deploying AI-driven robots; employees must be trained not only to operate these machines but also to understand how to interpret the data they generate.

Case Studies of Successful Implementation of AI-Driven Robots

Several companies have successfully implemented AI-driven robots in their assembly lines, showcasing the transformative potential of this technology. One notable example is Tesla, which has integrated advanced robotics into its production processes to enhance efficiency and scalability. Tesla’s Gigafactory employs a range of AI-driven robots that handle everything from battery cell production to vehicle assembly.

By utilizing machine learning algorithms, these robots can optimize their operations based on real-time data, significantly reducing production times while maintaining high-quality standards. Another compelling case study is that of Siemens, which has adopted AI-driven robotics in its electronics manufacturing division. Siemens implemented a system where robots equipped with AI capabilities could autonomously adjust their tasks based on variations in component sizes and types.

This flexibility allowed Siemens to streamline its production processes while minimizing waste and maximizing resource utilization. The success of these implementations demonstrates how AI-driven robots can lead to substantial improvements in productivity and operational efficiency across various industries.

Future Trends and Developments in AI-Driven Robots for Assembly Lines

As technology continues to evolve, the future of AI-driven robots in assembly lines looks promising. One emerging trend is the increasing use of collaborative robots, or cobots, which are designed to work alongside human operators rather than replace them. These cobots leverage AI to enhance human-robot collaboration, allowing for more complex tasks that require both human intuition and robotic precision.

This trend is particularly relevant in industries where human oversight is crucial for quality assurance. Additionally, advancements in machine learning and computer vision are expected to further enhance the capabilities of AI-driven robots. Future robots may be equipped with more sophisticated sensors that enable them to perceive their environment more accurately and make real-time adjustments based on visual feedback.

This could lead to even greater levels of automation and efficiency in assembly lines, as robots become capable of handling an even wider range of tasks with minimal human intervention.

Ethical and Social Implications of AI-Driven Robots in Manufacturing

The rise of AI-driven robots in manufacturing raises important ethical and social considerations that must be addressed as industries continue to evolve. One primary concern is the potential displacement of human workers due to increased automation. While AI-driven robots can enhance productivity and reduce costs, there is a legitimate fear that they may replace jobs traditionally held by humans, leading to unemployment and economic disparity.

Moreover, there are ethical questions surrounding decision-making processes within AI systems. As robots become more autonomous, issues related to accountability arise—who is responsible when an AI-driven robot makes a mistake or causes harm? Establishing clear guidelines and regulations will be essential to ensure that the deployment of these technologies aligns with societal values and ethical standards.

The Role of AI-Driven Robots in the Future of Assembly Line Flexibility

AI-driven robots are poised to play a pivotal role in shaping the future of assembly line flexibility and efficiency. Their ability to adapt quickly to changing demands, coupled with enhanced precision and continuous operation capabilities, positions them as invaluable assets in modern manufacturing environments. While challenges remain regarding implementation costs and ethical considerations, the potential benefits far outweigh these obstacles.

As industries continue to embrace digital transformation, the integration of AI-driven robotics will likely become a standard practice rather than an exception. The ongoing development of collaborative robots and advancements in machine learning will further enhance their capabilities, leading to smarter manufacturing processes that can respond dynamically to market needs. Ultimately, the successful integration of AI-driven robots into assembly lines will not only redefine operational efficiency but also contribute significantly to economic growth and innovation across various sectors.

A related article discussing the latest Samsung Galaxy S21 can be found here. This article explores the features and capabilities of the new smartphone, highlighting how advancements in technology are shaping the way we interact with devices. Just as AI-driven robots are revolutionizing assembly line flexibility, smartphones like the Galaxy S21 are pushing the boundaries of what is possible in the world of technology.

FAQs

What are AI-driven robots?

AI-driven robots are robots that are equipped with artificial intelligence (AI) technology, allowing them to perform tasks and make decisions without human intervention. These robots can learn from their experiences and adapt to new situations, making them more flexible and efficient in various applications.

How are AI-driven robots improving assembly line flexibility?

AI-driven robots are improving assembly line flexibility by being able to handle a wider range of tasks and adapt to changes in production requirements. They can be reprogrammed and retrained to perform different assembly tasks, making it easier for manufacturers to switch between different products and production processes.

What are the benefits of using AI-driven robots in assembly line operations?

The benefits of using AI-driven robots in assembly line operations include increased flexibility, improved efficiency, and reduced downtime. These robots can handle complex tasks with precision and speed, leading to higher productivity and lower production costs. Additionally, they can work alongside human workers, enhancing overall production capabilities.

How do AI-driven robots learn and adapt to new tasks?

AI-driven robots learn and adapt to new tasks through machine learning algorithms and sensor data. They can analyze and interpret information from their surroundings, allowing them to make decisions and adjust their actions accordingly. Over time, they can improve their performance and efficiency through continuous learning and experience.

What industries can benefit from the use of AI-driven robots in assembly line operations?

Various industries can benefit from the use of AI-driven robots in assembly line operations, including automotive, electronics, consumer goods, and pharmaceuticals. These robots can be deployed in manufacturing facilities to handle assembly, packaging, and quality control tasks, providing greater flexibility and productivity in production processes.