Additive manufacturing (AM), commonly referred to as 3D printing, has emerged as a transformative technology within the aerospace sector. This innovative approach to production allows for the layer-by-layer construction of components, enabling the creation of complex geometries that were previously unattainable through traditional manufacturing methods. The aerospace industry, characterized by its stringent safety standards and the need for lightweight yet durable materials, has found a natural ally in additive manufacturing.

As the demand for more efficient and cost-effective production methods grows, AM is increasingly being integrated into the design and manufacturing processes of aircraft and spacecraft. The adoption of additive manufacturing in aerospace design is not merely a trend; it represents a paradigm shift in how engineers and designers conceptualize and produce components. The ability to rapidly prototype parts, iterate designs, and produce small batches of highly specialized components has significant implications for the industry.

This technology facilitates innovation by allowing for more creative freedom in design, ultimately leading to enhanced performance and efficiency in aerospace applications. As we delve deeper into the advantages, impacts, and future trends of additive manufacturing in aerospace design, it becomes clear that this technology is reshaping the landscape of the industry.

Key Takeaways

- Additive manufacturing is revolutionizing aerospace design by allowing for the creation of complex and lightweight parts that were previously impossible to produce.

- The advantages of additive manufacturing in aerospace design include reduced material waste, faster production times, and the ability to create highly customized and optimized parts.

- Additive manufacturing has had a significant impact on aerospace design processes, leading to more efficient and cost-effective production methods.

- Case studies have shown how additive manufacturing has revolutionized aerospace design by enabling the creation of intricate and lightweight components, leading to improved performance and fuel efficiency.

- While additive manufacturing offers many benefits, there are still challenges and limitations to consider, such as material limitations, quality control, and the need for specialized expertise.

The Advantages of Additive Manufacturing in Aerospace Design

One of the most significant advantages of additive manufacturing in aerospace design is its ability to reduce weight without compromising structural integrity. Traditional manufacturing methods often require additional material to ensure strength, leading to heavier components. In contrast, AM allows for the optimization of designs through topology optimization and lattice structures, which can significantly reduce weight while maintaining strength.

For instance, components such as brackets and support structures can be designed with intricate internal geometries that minimize material usage while maximizing performance. Another key benefit of additive manufacturing is the reduction in lead times associated with production. In conventional manufacturing processes, creating molds or tooling can be time-consuming and costly.

AM eliminates much of this overhead by allowing direct production from digital files. This capability is particularly advantageous for the aerospace industry, where rapid prototyping can accelerate the development cycle of new aircraft or spacecraft. Companies can quickly iterate on designs based on testing and feedback, leading to faster innovation cycles and a more agile response to market demands.

The Impact of Additive Manufacturing on Aerospace Design Processes

The integration of additive manufacturing into aerospace design processes has fundamentally altered how engineers approach product development. Traditional design methodologies often involve a linear progression from concept to production, with multiple stages of prototyping and testing. However, AM enables a more iterative approach, where designs can be continuously refined based on real-time data and performance metrics.

This shift not only enhances collaboration among teams but also fosters a culture of innovation within organizations. Moreover, additive manufacturing facilitates the customization of components to meet specific requirements or preferences. In aerospace applications, where each aircraft may have unique specifications based on its intended use or mission profile, AM allows for tailored solutions that traditional methods cannot easily accommodate.

For example, a military aircraft may require specialized components that enhance stealth capabilities or improve aerodynamics. With AM, these bespoke parts can be produced efficiently without the need for extensive retooling or redesign.

Case Studies: How Additive Manufacturing Has Revolutionized Aerospace Design

Several notable case studies illustrate the profound impact of additive manufacturing on aerospace design. One prominent example is Boeing’s use of 3D printing for producing parts for its 787 Dreamliner. Boeing has successfully implemented AM to manufacture over 60 different parts for this aircraft model, including brackets and ducting systems.

By utilizing additive manufacturing, Boeing has achieved significant weight savings and reduced production costs while maintaining high safety standards. Another compelling case is that of GE Aviation, which has pioneered the use of additive manufacturing in jet engine production. The company has developed a fuel nozzle for its LEAP engine using 3D printing techniques.

This nozzle combines 18 individual parts into a single component, resulting in a lighter and more efficient design. The use of AM not only streamlined the manufacturing process but also improved performance by enhancing fuel efficiency and reducing emissions. Such innovations underscore how additive manufacturing is not just a supplementary tool but a core component of modern aerospace engineering.

Challenges and Limitations of Additive Manufacturing in Aerospace Design

Despite its numerous advantages, additive manufacturing in aerospace design is not without challenges and limitations. One significant hurdle is the certification process for AM-produced components.

The certification process for traditional components is well-established; however, AM introduces complexities due to the variability in production methods and materials. Establishing standardized testing protocols for AM parts remains an ongoing challenge that must be addressed to facilitate broader adoption. Additionally, material limitations pose another obstacle for additive manufacturing in aerospace applications.

While there has been significant progress in developing high-performance materials suitable for AM, such as titanium alloys and advanced polymers, the range of materials available is still limited compared to traditional manufacturing methods. This limitation can restrict design options and may necessitate compromises in performance or cost-effectiveness. As research continues into new materials and processes, overcoming these challenges will be crucial for realizing the full potential of additive manufacturing in aerospace design.

Future Trends and Innovations in Additive Manufacturing for Aerospace Design

Looking ahead, several trends and innovations are poised to shape the future of additive manufacturing in aerospace design. One notable trend is the increasing integration of artificial intelligence (AI) and machine learning into the design process. These technologies can analyze vast amounts of data to optimize designs for performance and manufacturability, enabling engineers to create more efficient components with less trial and error.

AI-driven generative design tools are already being explored by companies like Airbus to enhance their design capabilities. Another promising area of development is the advancement of multi-material printing technologies. The ability to print with multiple materials simultaneously opens up new possibilities for creating complex components with varying properties within a single part.

This capability could lead to innovations such as hybrid structures that combine lightweight materials with high-strength alloys, further pushing the boundaries of what is achievable in aerospace design.

The Role of Additive Manufacturing in Sustainable Aerospace Design

Sustainability is becoming an increasingly critical consideration in aerospace design, and additive manufacturing plays a vital role in this shift toward greener practices. By enabling lightweight designs that improve fuel efficiency, AM contributes directly to reducing carbon emissions associated with air travel. Furthermore, the ability to produce parts on-demand reduces waste associated with excess inventory and material scrap common in traditional manufacturing processes.

Additionally, additive manufacturing allows for localized production, which can significantly decrease transportation emissions associated with shipping parts across long distances. This localized approach not only supports sustainability goals but also enhances supply chain resilience by reducing dependency on global supply networks. As the aerospace industry continues to prioritize sustainability initiatives, additive manufacturing will be instrumental in driving these efforts forward.

The Future of Additive Manufacturing in Aerospace Design

As we look toward the future, it is evident that additive manufacturing will play an increasingly central role in shaping aerospace design and production processes. The technology’s ability to foster innovation through rapid prototyping, customization, and lightweighting aligns perfectly with the industry’s evolving demands for efficiency and sustainability. While challenges remain—particularly regarding certification and material limitations—the ongoing advancements in AM technology promise to overcome these hurdles.

The integration of AI, multi-material printing capabilities, and a focus on sustainable practices will further enhance the potential of additive manufacturing within aerospace design. As companies continue to explore new applications and refine their processes, it is clear that AM will not only revolutionize how aircraft and spacecraft are designed but also contribute significantly to a more sustainable future for aviation as a whole. The journey toward fully realizing the potential of additive manufacturing in aerospace is just beginning, but its trajectory suggests a future filled with innovation and opportunity.

Additive manufacturing, commonly known as 3D printing, is revolutionizing the aerospace industry by enabling more complex and lightweight designs that were previously impossible with traditional manufacturing methods. This transformation is not only enhancing the performance and efficiency of aerospace components but also reducing production costs and lead times. A related article that delves into the broader implications of technological advancements in different sectors is com/owned-by-vox-media-recode-is-a-technology-news-website/’>Owned by Vox Media, Recode is a Technology News Website.

This article provides insights into how technology is continuously reshaping industries, much like how additive manufacturing is impacting aerospace design.

FAQs

What is additive manufacturing?

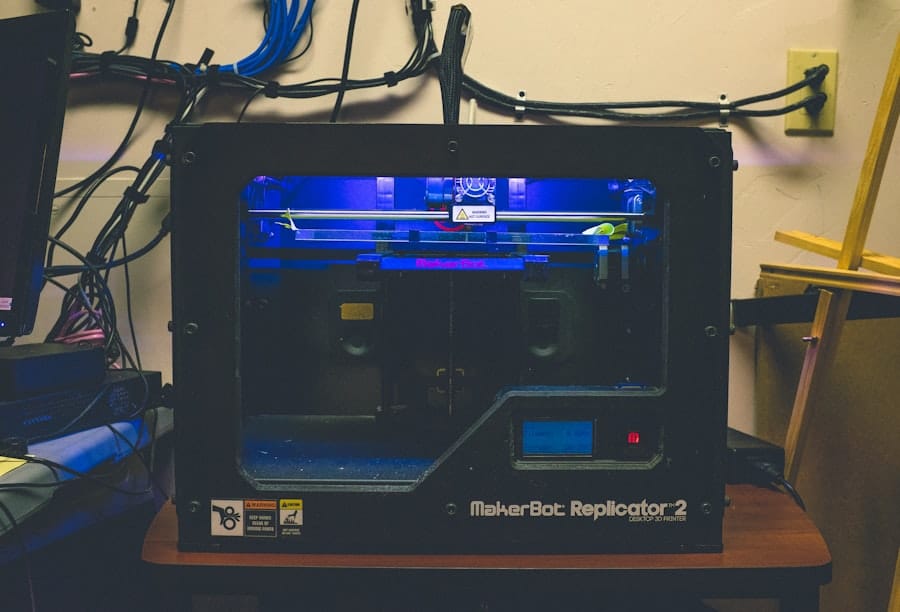

Additive manufacturing, also known as 3D printing, is a process of creating three-dimensional objects by adding material layer by layer based on a digital model.

How is additive manufacturing reshaping aerospace design?

Additive manufacturing is reshaping aerospace design by allowing for the creation of complex and lightweight parts that were previously impossible to produce using traditional manufacturing methods. This enables the design of more efficient and optimized aerospace components.

What are the benefits of using additive manufacturing in aerospace design?

Some benefits of using additive manufacturing in aerospace design include reduced weight, improved fuel efficiency, faster prototyping, and the ability to create complex geometries that improve performance.

What are some examples of aerospace components that can be produced using additive manufacturing?

Aerospace components that can be produced using additive manufacturing include engine parts, brackets, ducting, and even entire structural components such as wings and fuselage sections.

What are the challenges of using additive manufacturing in aerospace design?

Challenges of using additive manufacturing in aerospace design include the need for stringent quality control, material certification, and the development of new design and manufacturing standards to ensure the reliability and safety of printed components.