The advent of 3D printing technology has revolutionized the manufacturing landscape, offering innovative solutions that align with the growing demand for sustainability. This additive manufacturing process allows for the creation of three-dimensional objects from digital models, layer by layer, using various materials. Unlike traditional subtractive manufacturing methods, which often involve cutting away material from a solid block, 3D printing minimizes waste and optimizes resource use.

As industries grapple with the pressing need to reduce their environmental footprint, 3D printing emerges as a beacon of hope, promising not only efficiency but also a pathway toward more sustainable practices. The integration of 3D printing into manufacturing processes is not merely a trend; it represents a paradigm shift in how products are designed, produced, and distributed. By enabling localized production, 3D printing reduces the need for extensive supply chains and transportation, which are significant contributors to carbon emissions.

Furthermore, the technology allows for rapid prototyping and customization, empowering manufacturers to respond swiftly to market demands while minimizing excess inventory. As businesses increasingly recognize the importance of sustainability, 3D printing stands at the forefront of this transformation, offering a compelling alternative that aligns economic viability with environmental stewardship.

Key Takeaways

- 3D printing offers a sustainable alternative to traditional manufacturing methods by reducing waste and energy consumption.

- The environmental benefits of 3D printing include lower carbon emissions, reduced material usage, and the ability to recycle and reuse materials.

- 3D printing plays a crucial role in reducing waste in manufacturing by enabling on-demand production, customization, and the use of biodegradable materials.

- 3D printing materials such as bioplastics, recycled plastics, and bio-based materials offer sustainable properties that contribute to environmentally friendly manufacturing.

- Case studies demonstrate the potential of 3D printing for sustainable manufacturing, including the production of lightweight, energy-efficient parts and the creation of complex, optimized designs.

The Environmental Benefits of 3D Printing

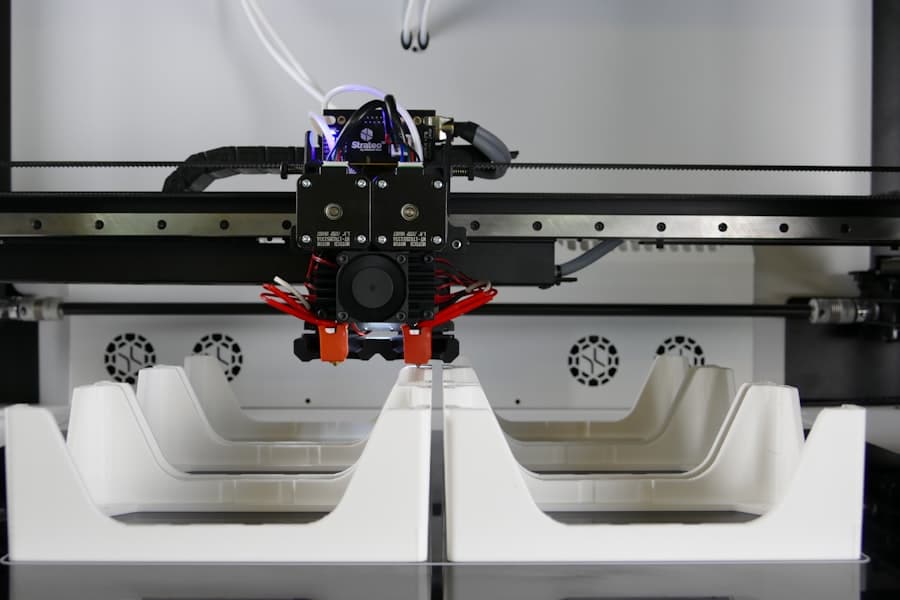

One of the most significant environmental benefits of 3D printing is its ability to drastically reduce material waste. Traditional manufacturing processes often result in substantial scrap material, as excess material is removed during production. In contrast, 3D printing is an additive process that builds objects layer by layer, using only the material necessary to create the final product.

This efficiency not only conserves resources but also reduces the energy consumption associated with material extraction and processing. For instance, studies have shown that 3D printing can reduce material waste by up to 90% compared to conventional methods, making it an attractive option for environmentally conscious manufacturers. Additionally, 3D printing facilitates the use of sustainable materials that can further enhance its environmental benefits.

Many companies are exploring bioplastics and recycled materials as viable options for 3D printing. These materials not only reduce reliance on fossil fuels but also contribute to a circular economy by repurposing waste into new products.

By utilizing such materials, manufacturers can significantly lower their carbon footprint while still achieving high-quality outputs.

The Role of 3D Printing in Reducing Waste in Manufacturing

The role of 3D printing in waste reduction extends beyond just material savings; it also encompasses the entire lifecycle of a product.

In contrast, 3D printing streamlines this process by allowing for rapid prototyping and iterative design directly within the production environment.

This capability enables designers to test and refine their products quickly, reducing the likelihood of producing flawed items that would ultimately be discarded. Moreover, 3D printing supports on-demand production, which significantly mitigates overproduction—a common issue in traditional manufacturing. By producing items only as needed, manufacturers can avoid excess inventory that may go unsold and eventually end up in landfills.

This just-in-time approach not only conserves resources but also enhances operational efficiency. For instance, companies like Adidas have adopted 3D printing technology to create customized footwear on demand, ensuring that each pair is tailored to individual customer preferences while minimizing waste associated with unsold stock.

3D Printing Materials and their Sustainable Properties

The choice of materials in 3D printing plays a crucial role in its sustainability profile. Traditional plastics used in manufacturing are often derived from non-renewable fossil fuels and can take centuries to decompose in landfills. However, advancements in material science have led to the development of eco-friendly alternatives that are both functional and sustainable.

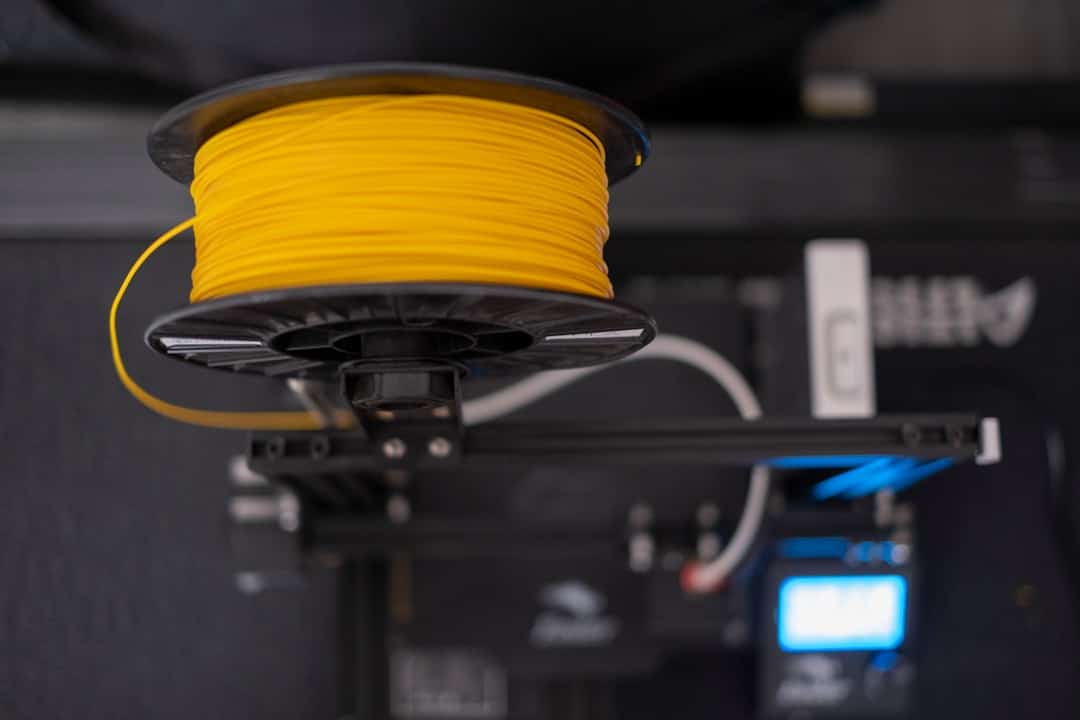

Biodegradable materials such as polylactic acid (PLA), derived from renewable resources like corn starch or sugarcane, are increasingly popular in 3D printing applications. PLA not only offers excellent printability but also breaks down more quickly than conventional plastics when exposed to composting conditions. In addition to biodegradable options, there is a growing interest in recycled materials for 3D printing.

Companies are now producing filaments made from post-consumer waste, such as discarded plastic bottles or industrial scrap. These recycled materials not only divert waste from landfills but also reduce the energy consumption associated with producing new plastic. For example, the company Refil offers filaments made from recycled PETG (polyethylene terephthalate glycol), which is known for its durability and versatility in various applications.

By utilizing these sustainable materials, manufacturers can significantly enhance the environmental performance of their products while maintaining high standards of quality.

Case Studies of Sustainable Manufacturing with 3D Printing

Several companies have successfully integrated 3D printing into their manufacturing processes to achieve sustainability goals. One notable example is General Electric (GE), which has embraced additive manufacturing for producing components in its jet engines. By utilizing 3D printing technology, GE has been able to reduce the weight of engine parts while simultaneously improving fuel efficiency.

The company estimates that its use of additive manufacturing has led to a reduction in material waste by approximately 90%, showcasing how traditional industries can leverage modern technology for sustainable outcomes. Another compelling case study is that of IKEA, which has explored 3D printing as a means to create sustainable furniture solutions. The company has experimented with producing components using recycled plastics and bioplastics, aiming to minimize its environmental impact while meeting consumer demand for customizable products.

By adopting 3D printing technology, IKEA not only enhances its design capabilities but also aligns its operations with its commitment to sustainability. This approach allows the company to offer innovative products while reducing reliance on virgin materials and decreasing overall waste.

Challenges and Limitations of Sustainable Manufacturing with 3D Printing

Despite its numerous advantages, sustainable manufacturing through 3D printing is not without challenges and limitations. One significant hurdle is the current state of material technology; while there are promising biodegradable and recycled materials available, they may not always match the performance characteristics of traditional plastics. This limitation can hinder their adoption in certain applications where strength, durability, or heat resistance is critical.

Manufacturers must carefully evaluate material properties to ensure that they meet industry standards while still prioritizing sustainability. Another challenge lies in the scalability of 3D printing technology for mass production. While additive manufacturing excels in creating customized or low-volume products efficiently, scaling up production to meet high demand can be complex and costly.

The speed of 3D printers varies significantly depending on the technology used and the complexity of the design, which can lead to longer lead times compared to traditional manufacturing methods. As industries seek to balance sustainability with economic viability, finding ways to optimize production processes while maintaining quality remains a key challenge.

The Future of 3D Printing in Sustainable Manufacturing

Looking ahead, the future of 3D printing in sustainable manufacturing appears promising as technological advancements continue to emerge. Innovations in material science are likely to yield even more sustainable options that offer enhanced performance characteristics while minimizing environmental impact. Researchers are actively exploring new biopolymers and composite materials that could expand the range of applications for sustainable 3D printing.

Moreover, as industries increasingly prioritize sustainability in their operations, regulatory frameworks may evolve to support and incentivize the adoption of eco-friendly practices. Governments and organizations may implement policies that encourage manufacturers to invest in sustainable technologies like 3D printing through grants or tax incentives. This shift could accelerate the transition toward more responsible manufacturing practices across various sectors.

The Potential of 3D Printing for Sustainable Manufacturing

The potential of 3D printing for sustainable manufacturing is vast and multifaceted. As industries face mounting pressure to reduce their environmental impact and embrace circular economy principles, additive manufacturing offers a viable solution that aligns economic interests with ecological responsibility. By minimizing waste, optimizing resource use, and enabling innovative design approaches, 3D printing stands poised to transform traditional manufacturing paradigms into more sustainable practices.

As we move forward into an era where sustainability is paramount, embracing technologies like 3D printing will be essential for manufacturers seeking to thrive in a competitive landscape while contributing positively to the planet’s health. The journey toward sustainable manufacturing is ongoing, but with continued investment in research and development, collaboration across sectors, and a commitment to innovation, the future looks bright for 3D printing as a cornerstone of sustainable industry practices.

In the pursuit of sustainable manufacturing, 3D printing has emerged as a revolutionary technology that offers significant environmental benefits. A related article that delves into the innovative aspects of digital assets is