Hazardous work environments are defined by the presence of conditions that pose significant risks to the health and safety of workers. These environments can be found in various industries, including construction, mining, chemical manufacturing, and waste management. The dangers inherent in these settings can range from exposure to toxic substances and extreme temperatures to the risk of physical injury from heavy machinery or unstable structures.

The Occupational Safety and Health Administration (OSHA) has established guidelines to help mitigate these risks, but the reality remains that many workers face daily threats to their well-being. The need for effective solutions to enhance safety in hazardous work environments has led to the exploration of advanced technologies, particularly robotics. As industries evolve and the demand for efficiency increases, the integration of robots into these settings has gained traction.

Robots can perform tasks that are too dangerous for humans, thereby reducing the likelihood of accidents and injuries. This shift not only protects workers but also improves productivity and operational efficiency. The intersection of robotics and hazardous work environments presents a compelling narrative about innovation, safety, and the future of work.

Key Takeaways

- Hazardous work environments pose significant risks to human workers

- Robots play a crucial role in performing tasks in hazardous work environments

- Case study demonstrates successful implementation of robots in hazardous work environments

- Benefits of using robots include increased safety and efficiency

- Challenges and limitations include high initial costs and potential job displacement

The Role of Robots in Hazardous Work Environments

Robots are increasingly being deployed in hazardous work environments to perform a variety of tasks that would otherwise expose human workers to danger. These tasks can include material handling, inspection, maintenance, and even emergency response. For instance, in the nuclear industry, robots are utilized to inspect and repair equipment in radioactive environments where human presence is limited due to safety concerns.

These robots are equipped with specialized sensors and cameras that allow them to gather data and perform necessary functions without risking human life. In addition to inspection and maintenance roles, robots are also being used in environments where chemical exposure is a significant risk. In chemical manufacturing plants, for example, robots can handle toxic substances during production processes, minimizing the risk of spills or leaks that could endanger human workers.

Furthermore, autonomous drones are being employed in hazardous areas such as oil rigs or disaster zones to conduct aerial surveys and gather critical information without putting personnel at risk.

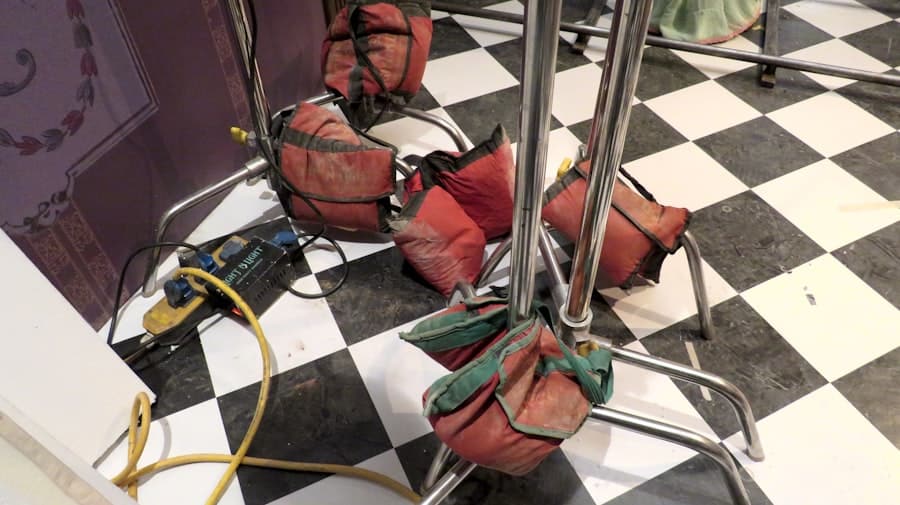

Case Study: Implementing Robots in Hazardous Work Environments

A notable example of successful robot implementation in a hazardous work environment can be found in the Fukushima Daiichi Nuclear Power Plant disaster response. Following the catastrophic earthquake and tsunami in 2011, which led to a nuclear meltdown, the Japanese government and Tokyo Electric Power Company (TEPCO) turned to robotics to assist in the cleanup and decommissioning efforts. Robots such as the PackBot and the Quince were deployed to navigate the highly radioactive environment, performing tasks such as debris removal and radiation measurement.

The PackBot, designed for military applications, was adapted for use in Fukushima due to its ability to traverse rough terrain and withstand radiation levels that would be lethal to humans. Equipped with cameras and radiation sensors, it provided real-time data on conditions within the plant, allowing engineers to make informed decisions about cleanup strategies. Similarly, the Quince robot was utilized for its ability to maneuver through tight spaces and collect samples from contaminated areas.

This case study illustrates not only the effectiveness of robots in hazardous environments but also their adaptability to meet specific challenges posed by unique situations.

Benefits of Using Robots in Hazardous Work Environments

The integration of robots into hazardous work environments offers numerous benefits that extend beyond mere safety enhancements. One of the most significant advantages is the reduction of workplace injuries and fatalities. By delegating dangerous tasks to robots, companies can significantly lower the risk of accidents that could result in serious harm or loss of life.

This shift not only protects employees but also fosters a culture of safety within organizations, which can lead to improved morale and productivity. Moreover, robots can operate continuously without the need for breaks or rest periods, leading to increased efficiency and productivity. In industries where time is critical—such as emergency response or disaster recovery—robots can perform tasks more quickly than human workers while maintaining a high level of precision.

For instance, in mining operations, autonomous vehicles can transport materials from hazardous areas without exposing human operators to potential dangers such as cave-ins or toxic gas exposure. This capability not only streamlines operations but also allows human workers to focus on more complex tasks that require critical thinking and problem-solving skills.

Challenges and Limitations of Using Robots in Hazardous Work Environments

Despite the numerous advantages associated with robotic integration into hazardous work environments, several challenges and limitations must be addressed. One significant concern is the high initial cost of implementing robotic systems. The investment required for advanced robotics technology can be substantial, particularly for small to medium-sized enterprises that may struggle to allocate resources for such innovations.

Additionally, ongoing maintenance and updates are necessary to ensure that robotic systems remain functional and effective over time. Another challenge lies in the complexity of programming robots to operate safely and effectively in unpredictable environments. While advancements in artificial intelligence have improved robotic capabilities, there are still limitations regarding their ability to adapt to unforeseen circumstances or make real-time decisions based on changing conditions.

For example, a robot deployed in a disaster zone may encounter obstacles or hazards that were not accounted for during its programming, potentially leading to operational failures or safety risks. Ensuring that robots can navigate these complexities requires ongoing research and development efforts.

Safety Measures and Regulations for Robots in Hazardous Work Environments

The deployment of robots in hazardous work environments necessitates stringent safety measures and adherence to regulations designed to protect both human workers and robotic systems. Regulatory bodies such as OSHA have established guidelines that govern the use of robotics in various industries, emphasizing the importance of risk assessments and safety protocols. These regulations often require companies to conduct thorough evaluations of their work environments before integrating robotic systems, ensuring that potential hazards are identified and mitigated.

In addition to regulatory compliance, organizations must implement comprehensive training programs for employees who will interact with robotic systems. This training should cover not only how to operate the robots but also how to respond effectively in case of malfunctions or emergencies. Furthermore, regular maintenance checks and updates are essential to ensure that robotic systems remain safe and reliable over time.

By prioritizing safety measures and adhering to regulations, companies can create a safer work environment while maximizing the benefits of robotic technology.

Future Outlook for Robots in Hazardous Work Environments

The future outlook for robots in hazardous work environments is promising, with ongoing advancements in technology poised to further enhance their capabilities. As artificial intelligence continues to evolve, robots will become increasingly adept at performing complex tasks autonomously while adapting to dynamic conditions. This evolution will likely lead to broader applications across various industries, including construction, mining, healthcare, and emergency response.

The integration of robotics into hazardous work environments aligns with this trend by providing a means to reduce risks while maintaining productivity levels. As industries continue to embrace automation and robotics, we can expect a significant transformation in how hazardous tasks are approached, ultimately leading to safer workplaces for all.

The Impact of Robots in Hazardous Work Environments

The impact of robots in hazardous work environments is profound and multifaceted. By taking on dangerous tasks traditionally performed by humans, robots not only enhance safety but also improve operational efficiency across various industries. The successful implementation of robotic systems in challenging settings—such as nuclear disaster recovery—demonstrates their potential to revolutionize how we approach workplace hazards.

As technology continues to advance and regulatory frameworks evolve, the role of robots in hazardous work environments will likely expand further. The ongoing development of smarter, more adaptable robotic systems will enable industries to tackle increasingly complex challenges while prioritizing worker safety. Ultimately, the integration of robotics into hazardous work environments represents a significant step forward in creating safer workplaces for future generations.

In the realm of technology and innovation, robots are increasingly being utilized to support hazardous work environments, as highlighted in the “Case Study: Robots Supporting Hazardous Work Environments.” A related article that delves into the technological advancements and their implications in various fields is “Discover the Best Paying Jobs in Tech 2023.” This article explores the evolving landscape of tech jobs, many of which are driven by advancements in robotics and automation. For more insights, you can read the full article here.

FAQs

What are hazardous work environments?

Hazardous work environments are workplaces where employees are exposed to conditions that could cause harm, injury, illness, or death. These environments can include exposure to chemicals, extreme temperatures, high noise levels, radiation, and other dangerous conditions.

How can robots support hazardous work environments?

Robots can support hazardous work environments by performing tasks that are too dangerous for humans to do safely. They can be used for tasks such as handling hazardous materials, working in extreme temperatures, and performing tasks in areas with high levels of radiation.

What are the benefits of using robots in hazardous work environments?

Using robots in hazardous work environments can help to protect human workers from dangerous conditions and reduce the risk of injury or illness. Robots can also improve efficiency and productivity in these environments by performing tasks more quickly and accurately than humans.

What are some examples of robots used in hazardous work environments?

Some examples of robots used in hazardous work environments include remotely operated vehicles (ROVs) for underwater tasks, robotic arms for handling hazardous materials, and drones for inspecting and monitoring hazardous areas.

What are the challenges of using robots in hazardous work environments?

Challenges of using robots in hazardous work environments include the high cost of acquiring and maintaining robotic systems, the need for specialized training to operate and maintain the robots, and the limitations of current robotic technology in certain hazardous conditions.