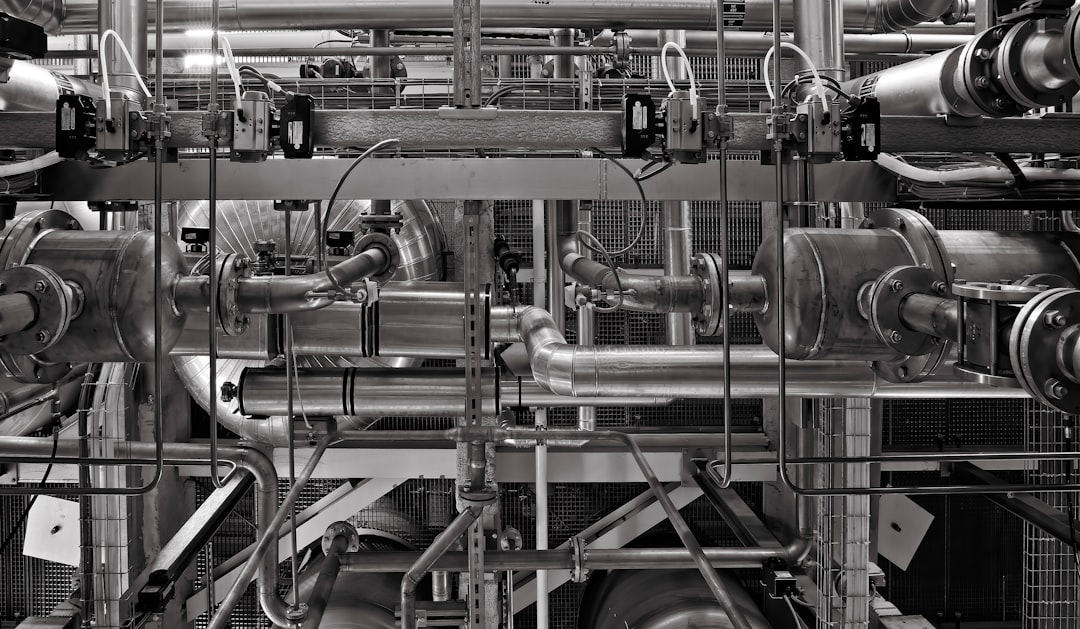

The advent of artificial intelligence (AI) has ushered in a transformative era for various industries, with manufacturing standing out as a sector ripe for innovation. Smart manufacturing, characterized by the integration of advanced technologies such as AI, the Internet of Things (IoT), and big data analytics, is revolutionizing traditional production methods. This paradigm shift not only enhances operational efficiency but also significantly improves quality control processes.

By leveraging AI, manufacturers can analyze vast amounts of data in real-time, enabling them to make informed decisions that optimize production lines and ensure product quality. AI’s role in smart manufacturing extends beyond mere automation; it encompasses predictive analytics, machine learning, and advanced robotics. These technologies work in concert to create a more agile and responsive manufacturing environment.

For instance, AI algorithms can predict equipment failures before they occur, allowing for proactive maintenance that minimizes downtime. Furthermore, AI-driven quality control systems can identify defects in products at an unprecedented speed and accuracy, ensuring that only the highest quality items reach consumers. As industries continue to embrace these innovations, the potential for AI to reshape manufacturing processes and quality assurance becomes increasingly evident.

Key Takeaways

- AI enhances manufacturing processes by enabling smarter, automated quality control systems.

- Implementation of AI involves integrating machine learning and data analytics into production lines.

- Benefits include improved defect detection, reduced waste, and increased production efficiency.

- Case studies show significant performance gains and cost savings after AI adoption.

- Challenges remain in data quality, system integration, and adapting to evolving manufacturing needs.

Implementation of AI in Manufacturing Processes

The implementation of AI in manufacturing processes involves a multifaceted approach that integrates various technologies and methodologies. One of the primary applications of AI is in predictive maintenance, where machine learning algorithms analyze historical data from equipment sensors to forecast potential failures. This proactive approach not only reduces unplanned downtime but also extends the lifespan of machinery.

For example, a manufacturer might employ AI to monitor vibration patterns in motors; deviations from normal patterns can trigger alerts for maintenance before a breakdown occurs. Another significant area where AI is making strides is in supply chain optimization. By utilizing AI algorithms to analyze market trends, inventory levels, and production schedules, manufacturers can streamline their supply chains to reduce costs and improve efficiency.

For instance, an automotive manufacturer might use AI to predict demand for specific vehicle models based on historical sales data and current market conditions. This allows them to adjust production schedules accordingly, minimizing excess inventory and ensuring that they meet customer demand without overextending resources.

Benefits of AI in Quality Control

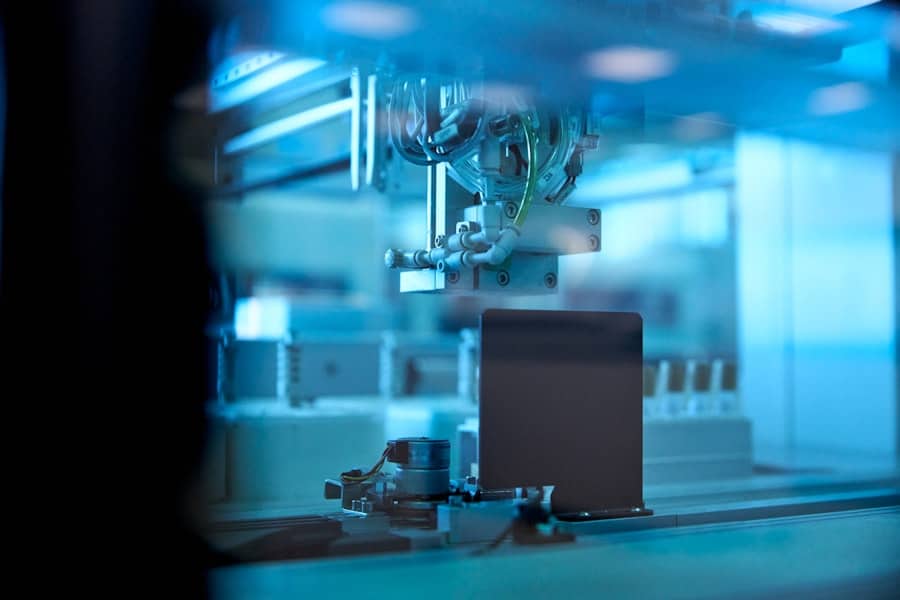

The integration of AI into quality control processes offers numerous advantages that enhance product reliability and customer satisfaction. One of the most notable benefits is the ability to conduct real-time inspections using computer vision technology. AI-powered cameras can analyze products on the assembly line at high speeds, identifying defects that human inspectors might miss.

This level of precision not only improves the overall quality of products but also reduces the likelihood of costly recalls due to defective items reaching consumers.

Machine learning algorithms can adapt to new types of defects or changes in production processes, ensuring that quality control measures remain effective even as manufacturing conditions evolve.

For example, a food processing plant might implement an AI system that learns to detect subtle changes in product color or texture that indicate spoilage or contamination. This capability not only enhances food safety but also builds consumer trust in the brand.

Case Study: AI Implementation in a Manufacturing Plant

A compelling case study illustrating the successful implementation of AI in manufacturing is that of Siemens’ Amberg Electronics Plant in Germany. This facility has integrated AI-driven technologies into its production processes, resulting in significant improvements in efficiency and quality control. The plant employs a sophisticated system that utilizes machine learning algorithms to monitor production lines and analyze data from various sensors embedded in machinery.

One notable application at the Amberg plant is the use of AI for real-time quality assurance. The system continuously evaluates product quality during assembly by comparing real-time data against predefined standards. If a deviation is detected, the system can automatically adjust parameters or alert operators to take corrective action.

This proactive approach has led to a remarkable reduction in defect rates, with the plant achieving an impressive 99.99885% quality rate for its products.

Results and Impact of AI in Smart Manufacturing

| Metric | Description | Before AI Implementation | After AI Implementation | Improvement |

|---|---|---|---|---|

| Defect Detection Accuracy | Percentage of defects correctly identified during quality control | 85% | 97% | +12% |

| Inspection Time per Unit | Average time taken to inspect each product unit (seconds) | 45 | 15 | -66.7% |

| Production Downtime | Hours of downtime due to quality issues or machine faults per month | 20 | 8 | -60% |

| Yield Rate | Percentage of products meeting quality standards on first pass | 92% | 98% | +6% |

| Cost of Quality Control | Resources spent on quality control per 1000 units | 1200 | 700 | -41.7% |

| Operator Intervention | Number of manual inspections required per shift | 50 | 10 | -80% |

The results of implementing AI in smart manufacturing are profound and far-reaching. Companies that have adopted these technologies report not only enhanced operational efficiency but also significant cost savings. For instance, manufacturers have observed reductions in production cycle times due to optimized workflows driven by AI insights.

By analyzing data from various stages of production, companies can identify bottlenecks and streamline processes, leading to faster turnaround times and increased output. Additionally, the impact on product quality cannot be overstated. With AI systems capable of detecting defects early in the production process, manufacturers can address issues before they escalate into larger problems.

This proactive approach not only minimizes waste but also enhances customer satisfaction by ensuring that only high-quality products reach the market. As a result, companies experience improved brand reputation and customer loyalty, which are critical factors for long-term success in a competitive landscape.

Challenges and Limitations of AI in Quality Control

Despite the numerous benefits associated with AI in quality control, several challenges and limitations must be addressed for successful implementation. One significant hurdle is the initial investment required for integrating AI technologies into existing manufacturing systems. Many companies may find it challenging to allocate resources for advanced technologies, particularly small to medium-sized enterprises (SMEs) that operate on tighter budgets.

Moreover, there is often a skills gap when it comes to managing and interpreting data generated by AI systems. Manufacturers may struggle to find personnel with the necessary expertise in data science and machine learning to effectively utilize these technologies. This lack of skilled labor can hinder the full realization of AI’s potential benefits in quality control processes.

Additionally, concerns regarding data privacy and security must be addressed as manufacturers increasingly rely on interconnected systems that share sensitive information across networks.

Future Trends and Developments in AI for Smart Manufacturing

Looking ahead, several trends are poised to shape the future of AI in smart manufacturing and quality control. One emerging trend is the increasing adoption of edge computing, which allows data processing to occur closer to the source rather than relying solely on centralized cloud systems. This shift enables real-time decision-making and reduces latency, making it particularly beneficial for applications requiring immediate responses, such as quality inspections on fast-moving assembly lines.

Another significant development is the growing emphasis on collaborative robots (cobots) that work alongside human operators on the factory floor. These robots are equipped with AI capabilities that allow them to learn from human actions and adapt their behavior accordingly. As cobots become more prevalent, they will enhance productivity while ensuring that human workers can focus on more complex tasks that require critical thinking and creativity.

The Role of AI in Driving Efficiency and Quality in Manufacturing

The integration of artificial intelligence into smart manufacturing represents a pivotal shift towards more efficient and high-quality production processes. By harnessing the power of AI technologies, manufacturers can optimize operations, enhance quality control measures, and ultimately deliver superior products to consumers. As industries continue to evolve and embrace these innovations, the role of AI will undoubtedly become increasingly central to driving efficiency and maintaining competitive advantage in the global marketplace.

In summary, while challenges remain regarding implementation costs and skills gaps, the potential benefits of AI in manufacturing are too significant to overlook. As companies navigate this transformative landscape, those that invest in AI technologies will likely emerge as leaders in their respective fields, setting new standards for quality and operational excellence. The future of manufacturing is undoubtedly intertwined with advancements in artificial intelligence, paving the way for smarter factories that are more responsive to market demands and consumer expectations.

In the realm of smart manufacturing and quality control, the integration of advanced technologies is crucial for optimizing processes and enhancing productivity. A related article that delves into the importance of innovative tools in various fields is the Ultimate Guide to the Best Lighting Design Software of 2023, which explores how cutting-edge software can improve design efficiency and accuracy, paralleling the advancements seen in AI applications within manufacturing.

FAQs

What is smart manufacturing?

Smart manufacturing refers to the use of advanced technologies such as IoT, AI, robotics, and data analytics to optimize production processes, improve efficiency, and reduce costs in manufacturing environments.

How is AI used in smart manufacturing?

AI is used in smart manufacturing for predictive maintenance, process optimization, defect detection, supply chain management, and real-time decision-making to enhance productivity and product quality.

What role does AI play in quality control?

AI helps in quality control by automating inspection processes, identifying defects through image recognition, analyzing production data to detect anomalies, and ensuring consistent product standards.

What are the benefits of integrating AI in manufacturing?

Benefits include increased operational efficiency, reduced downtime, improved product quality, faster decision-making, cost savings, and enhanced flexibility in production processes.

Can AI systems predict equipment failures?

Yes, AI systems use predictive analytics and sensor data to forecast equipment failures before they occur, enabling proactive maintenance and minimizing unplanned downtime.

What types of AI technologies are commonly used in manufacturing?

Common AI technologies include machine learning, computer vision, natural language processing, robotics, and deep learning algorithms.

Is AI in manufacturing cost-effective?

While initial implementation can be costly, AI often leads to long-term cost savings through improved efficiency, reduced waste, and lower maintenance expenses.

How does AI improve defect detection?

AI uses computer vision and machine learning models to analyze images and sensor data, identifying defects more accurately and faster than traditional manual inspection methods.

What challenges exist in implementing AI in manufacturing?

Challenges include data quality and integration, high initial investment, workforce training, cybersecurity concerns, and the need for ongoing system maintenance.

How does AI contribute to sustainability in manufacturing?

AI optimizes resource usage, reduces waste, improves energy efficiency, and supports sustainable supply chain management, contributing to greener manufacturing practices.