Artificial intelligence (AI) is transforming manufacturing operations across multiple industries. Smart manufacturing integrates technologies including the Internet of Things (IoT), big data analytics, and AI to modernize production processes. These technologies increase operational efficiency and enhance quality control capabilities.

Manufacturers implement AI systems to remain competitive in global markets. Real-time data analysis enables faster decision-making, resulting in improved product quality and customer satisfaction. Quality control maintains product standards and ensures customer requirements are met throughout manufacturing processes.

AI integration in quality control systems allows manufacturers to identify defects earlier in production cycles, reducing material waste and increasing product reliability.

These systems optimize manufacturing operations and provide data-driven insights that support continuous improvement initiatives, leading to enhanced product quality and operational performance.

Key Takeaways

- AI enhances efficiency and accuracy in manufacturing processes, leading to improved quality control.

- Real-world case studies demonstrate successful AI integration in smart manufacturing facilities.

- AI adoption offers significant benefits but also presents challenges such as implementation complexity.

- Improved product quality through AI positively impacts customer satisfaction and brand reputation.

- Future trends indicate growing AI capabilities, urging companies to strategically plan AI implementation.

The Role of AI in Improving Efficiency and Accuracy in Manufacturing Processes

AI plays a pivotal role in enhancing both efficiency and accuracy within manufacturing processes. One of the most significant contributions of AI is its ability to optimize production schedules through predictive analytics. By analyzing historical data and current production metrics, AI systems can forecast demand fluctuations and adjust manufacturing schedules accordingly.

This dynamic scheduling minimizes downtime and maximizes resource utilization, ensuring that production lines operate at peak efficiency. For instance, a manufacturer producing automotive components can use AI algorithms to predict when certain parts will be in high demand, allowing them to ramp up production in advance and avoid bottlenecks. Moreover, AI enhances accuracy in manufacturing by reducing human error through automation.

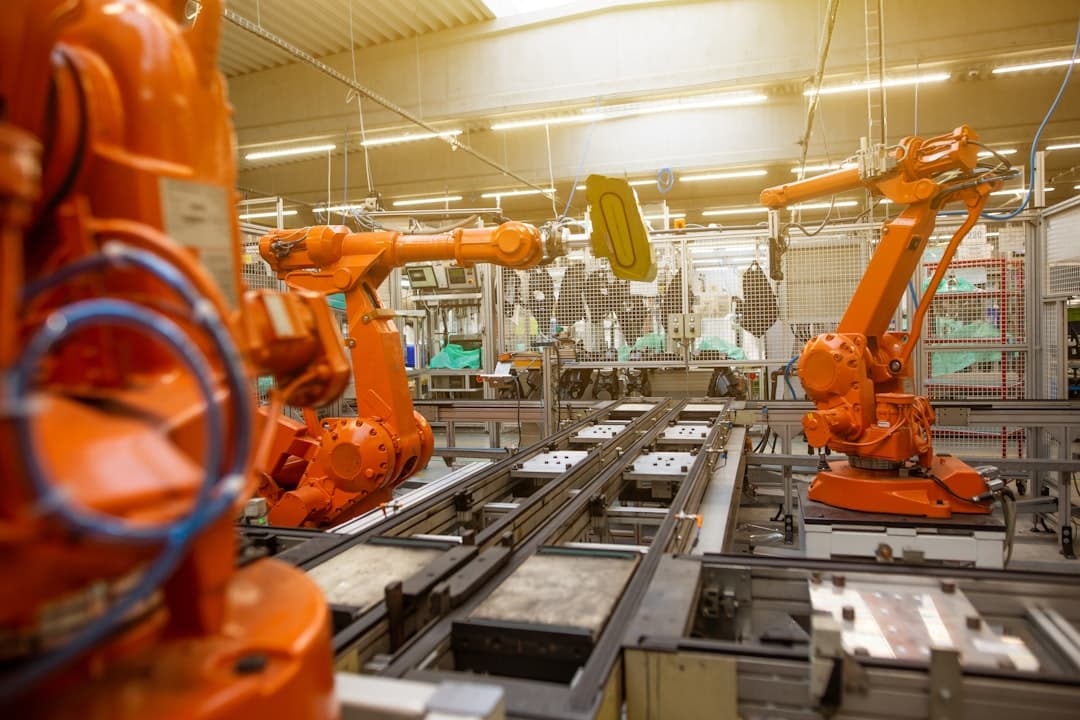

Traditional manufacturing processes often rely on manual labor for tasks such as assembly and quality inspection, which can lead to inconsistencies and defects. By implementing AI-driven robotic systems, manufacturers can achieve higher precision in repetitive tasks. For example, collaborative robots (cobots) equipped with AI capabilities can work alongside human operators to perform intricate assembly tasks with remarkable accuracy.

These robots can learn from their environment and adapt to changes in real-time, ensuring that each product meets stringent quality standards without the variability associated with human labor.

Case Study: Implementation of AI in a Smart Manufacturing Facility

A compelling example of AI implementation in smart manufacturing can be observed at Siemens’ Amberg Electronics Plant in Germany. This facility has integrated AI technologies into its production processes to enhance efficiency and quality control. The plant employs a sophisticated network of sensors and IoT devices that collect data from various stages of production.

This data is then analyzed using machine learning algorithms to identify patterns and anomalies that could indicate potential issues. One notable application of AI at the Amberg facility is its predictive maintenance program. By continuously monitoring equipment performance and analyzing historical maintenance data, the AI system can predict when a machine is likely to fail or require servicing.

This proactive approach minimizes unplanned downtime and extends the lifespan of machinery, ultimately leading to significant cost savings. Additionally, the plant utilizes AI-driven quality control systems that employ computer vision technology to inspect products at various stages of production. These systems can detect defects with a high degree of accuracy, allowing for immediate corrective actions to be taken before defective products reach the market.

Benefits and Challenges of Using AI in Quality Control

The benefits of incorporating AI into quality control processes are manifold. One of the most significant advantages is the ability to conduct real-time inspections with unparalleled speed and accuracy. Traditional quality control methods often involve manual inspections that can be time-consuming and prone to human error.

In contrast, AI-powered systems can analyze images and data instantaneously, identifying defects that may go unnoticed by the human eye. This capability not only enhances product quality but also accelerates the overall production process, allowing manufacturers to respond more swiftly to market demands. However, the implementation of AI in quality control is not without its challenges.

One major hurdle is the initial investment required for technology acquisition and integration. Many manufacturers may hesitate to adopt AI due to concerns about the costs associated with upgrading existing systems or training personnel to work with new technologies. Additionally, there is often a steep learning curve associated with deploying AI solutions effectively.

Companies must invest time and resources into understanding how to leverage these technologies fully, which can be daunting for organizations lacking technical expertise.

Impact of AI on Product Quality and Customer Satisfaction

| Metric | Description | Before AI Implementation | After AI Implementation | Improvement |

|---|---|---|---|---|

| Defect Detection Accuracy | Percentage of defects correctly identified during quality control | 85% | 97% | +12% |

| Inspection Time per Unit | Average time taken to inspect each product unit (seconds) | 45 sec | 15 sec | -66.7% |

| Production Downtime | Hours of downtime due to quality issues or machine faults per month | 20 hrs | 8 hrs | -60% |

| Yield Rate | Percentage of products passing quality control on first inspection | 92% | 98.5% | +6.5% |

| Cost of Quality Control | Cost associated with quality control processes per 1000 units | 1200 | 700 | -41.7% |

| Employee Productivity | Units inspected per employee per hour | 40 | 120 | +200% |

The impact of AI on product quality is profound, leading to enhanced customer satisfaction as a direct consequence. By utilizing AI-driven quality control systems, manufacturers can ensure that their products consistently meet or exceed industry standards. This reliability fosters trust among consumers, who are increasingly discerning about product quality in today’s competitive marketplace.

For instance, companies in the electronics sector have reported significant reductions in defect rates after implementing AI-based inspection systems, resulting in fewer returns and higher customer satisfaction ratings. Moreover, AI enables manufacturers to personalize products based on customer preferences and feedback. By analyzing consumer data and market trends, companies can tailor their offerings to better align with customer expectations.

This level of customization not only enhances product appeal but also strengthens brand loyalty. For example, a clothing manufacturer utilizing AI algorithms can analyze purchasing patterns to predict which styles will resonate with specific demographics, allowing them to produce items that are more likely to sell well.

Future Trends and Developments in AI for Smart Manufacturing and Quality Control

As technology continues to evolve, several trends are emerging that will shape the future of AI in smart manufacturing and quality control. One notable trend is the increasing use of edge computing in conjunction with AI technologies. Edge computing allows data processing to occur closer to the source of data generation—such as machines on the factory floor—rather than relying solely on centralized cloud computing resources.

This shift enables faster decision-making and reduces latency, which is crucial for real-time applications like quality control. Another significant development is the growing emphasis on explainable AI (XAI). As manufacturers adopt more complex AI systems, there is a pressing need for transparency regarding how these systems make decisions.

Explainable AI aims to provide insights into the reasoning behind AI-driven outcomes, allowing operators to understand why certain actions are taken or why specific defects are identified during inspections. This transparency not only builds trust among users but also facilitates better collaboration between human operators and AI systems.

The Potential of AI in Transforming the Manufacturing Industry

The potential of AI in transforming the manufacturing industry is immense, offering opportunities for enhanced efficiency, accuracy, and product quality. As manufacturers increasingly embrace smart technologies, they position themselves to thrive in an ever-evolving landscape characterized by rapid technological advancements and shifting consumer expectations. The integration of AI into manufacturing processes not only streamlines operations but also fosters a culture of innovation where continuous improvement becomes the norm.

As this technology continues to mature, it will undoubtedly play a pivotal role in shaping the future of manufacturing.

Recommendations for Companies Looking to Implement AI in Smart Manufacturing and Quality Control

For companies considering the implementation of AI in their smart manufacturing and quality control processes, several recommendations can facilitate a successful transition. First and foremost, it is essential to conduct a thorough assessment of existing processes and identify specific areas where AI can add value. This targeted approach ensures that investments are made strategically rather than adopting technology for technology’s sake.

Additionally, fostering a culture of collaboration between IT specialists and manufacturing personnel is crucial for successful implementation. Engaging employees at all levels in discussions about how AI can enhance their work will promote buy-in and facilitate smoother integration into existing workflows. Training programs should be established to equip staff with the necessary skills to work alongside AI systems effectively.

Finally, companies should remain agile and open to continuous learning as they navigate their AI journey. The landscape of technology is ever-changing; therefore, staying informed about emerging trends and best practices will enable organizations to adapt their strategies accordingly. By embracing innovation while remaining grounded in their core values, manufacturers can leverage AI not just as a tool but as a catalyst for transformative change within their operations.

In the realm of smart manufacturing and quality control, the integration of AI technologies is transforming traditional processes into more efficient and precise operations. For those interested in exploring the broader implications of technology advancements, a related article can be found at CNET’s coverage of the latest consumer technology breakthroughs, which highlights how innovations in various sectors, including manufacturing, are reshaping the landscape of industry standards and practices.

FAQs

What is smart manufacturing?

Smart manufacturing refers to the use of advanced technologies such as IoT, AI, robotics, and data analytics to optimize production processes, improve efficiency, and reduce costs in manufacturing environments.

How is AI used in smart manufacturing?

AI is used in smart manufacturing for predictive maintenance, process optimization, defect detection, supply chain management, and real-time decision-making to enhance productivity and product quality.

What role does AI play in quality control?

AI helps in quality control by automating inspection processes, identifying defects through image recognition, analyzing production data to detect anomalies, and ensuring consistent product standards.

What are the benefits of integrating AI in manufacturing?

Benefits include increased operational efficiency, reduced downtime, improved product quality, faster decision-making, cost savings, and enhanced flexibility in production processes.

Can AI predict equipment failures in manufacturing?

Yes, AI algorithms analyze sensor data to predict equipment failures before they occur, enabling proactive maintenance and minimizing unplanned downtime.

What types of AI technologies are commonly used in smart manufacturing?

Common AI technologies include machine learning, computer vision, natural language processing, and robotics, all of which contribute to automation and intelligent decision-making.

Is AI in manufacturing cost-effective?

While initial implementation can be costly, AI often leads to long-term cost savings through improved efficiency, reduced waste, and lower maintenance expenses.

How does AI improve product quality?

AI improves product quality by detecting defects early, optimizing manufacturing parameters, and ensuring consistent adherence to quality standards throughout the production process.

What challenges exist when implementing AI in manufacturing?

Challenges include data integration, high initial investment, workforce training, cybersecurity concerns, and ensuring AI models are accurate and reliable.

Is AI replacing human workers in manufacturing?

AI is augmenting human workers by automating repetitive tasks and providing decision support, but it generally complements rather than fully replaces human roles in manufacturing.