3D printing, also known as additive manufacturing, is a revolutionary technology that creates three-dimensional objects from digital files. The process involves layering materials to build an object from the ground up, which contrasts sharply with traditional subtractive manufacturing methods that cut away material from a solid block. The origins of 3D printing date back to the 1980s when Chuck Hull invented stereolithography, a technique that uses ultraviolet light to cure liquid resin into solid forms.

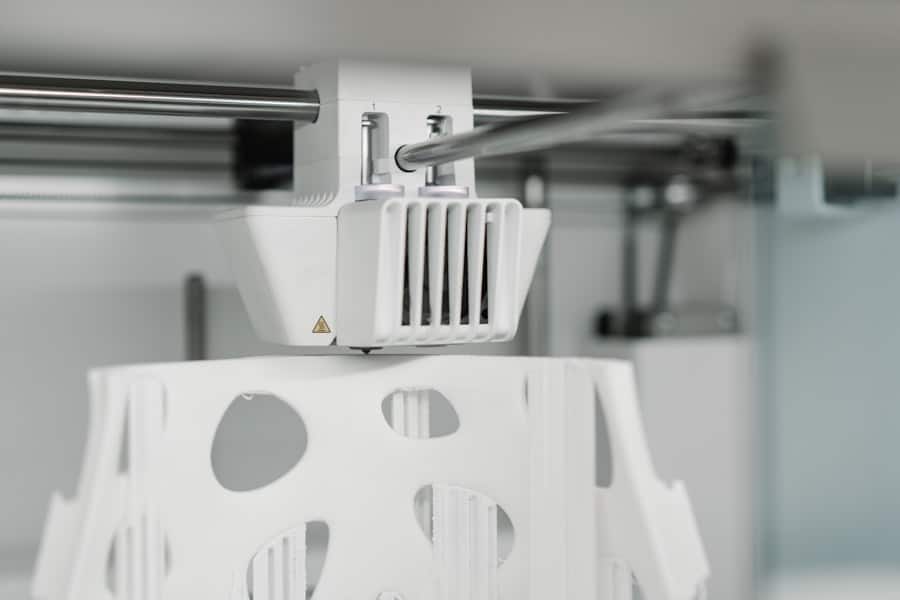

Since then, the technology has evolved significantly, leading to various methods such as Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). At its core, 3D printing operates on a simple principle: a digital model is sliced into thin horizontal layers, which the printer then reproduces one layer at a time. This process allows for intricate designs and complex geometries that would be difficult or impossible to achieve with traditional manufacturing techniques.

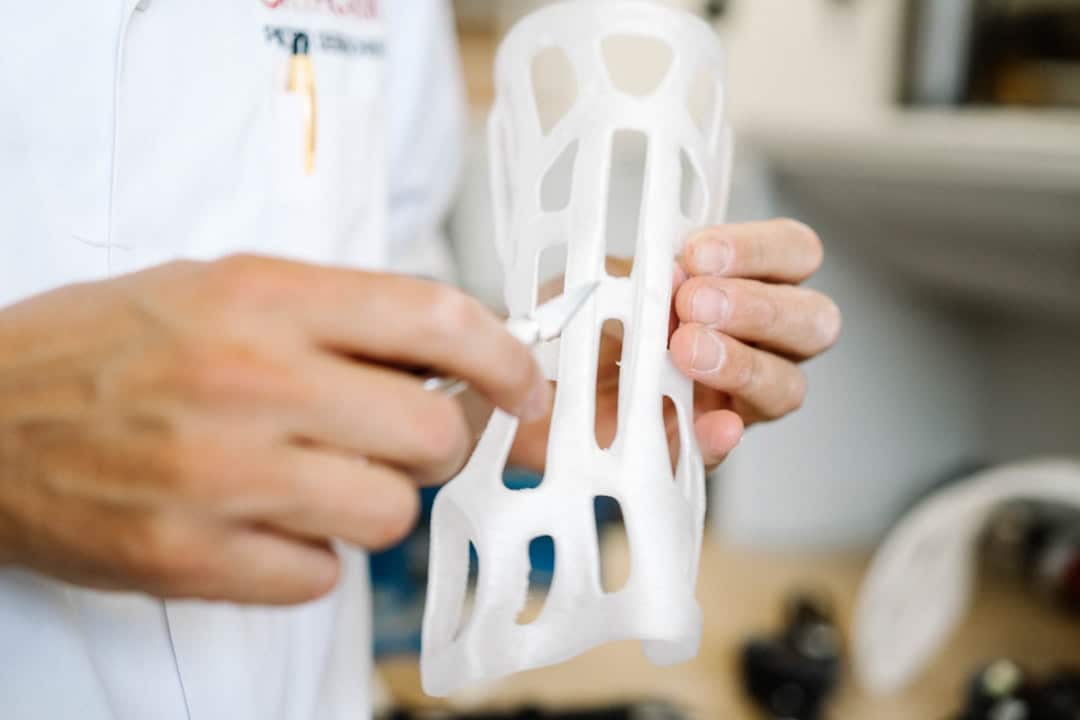

The versatility of 3D printing has made it applicable across numerous industries, including aerospace, automotive, healthcare, and consumer goods. As the technology continues to advance, it opens up new avenues for innovation, customization, and efficiency in production.

Key Takeaways

- 3D printing is a process of creating three-dimensional objects from a digital file using a 3D printer.

- Consider factors such as print quality, build volume, and material compatibility when choosing the right 3D printer for your needs.

- Essential software and tools for 3D printing include CAD software for designing, slicing software for preparing the 3D model for printing, and a 3D printer.

- Materials for 3D printing include filaments (PLA, ABS, PETG), resins (SLA, DLP), and more, each with unique properties and applications.

- Getting started with 3D printing involves steps such as designing or downloading a 3D model, slicing it, and then printing it using a 3D printer.

Choosing the Right 3D Printer for Your Needs

Selecting the appropriate 3D printer is crucial for achieving desired results, whether for personal projects or professional applications. The first step in this decision-making process is to identify the primary purpose of the printer. For hobbyists and beginners, entry-level FDM printers are often the most accessible and affordable option.

These printers use thermoplastic filaments and are known for their ease of use and wide availability of materials. Popular models like the Creality Ender 3 or Prusa Mini offer a good balance of quality and cost, making them ideal for those just starting in the world of 3D printing. For more advanced users or specific applications, such as prototyping or industrial production, one might consider higher-end options like SLA or SLS printers.

SLA printers utilize a laser to cure resin layer by layer, resulting in high-resolution prints with smooth finishes. On the other hand, SLS printers use a laser to fuse powdered materials, allowing for complex geometries and functional parts. Brands like Formlabs and EOS are well-regarded in these categories, providing machines that cater to professional needs.

Ultimately, understanding your requirements—be it print size, material compatibility, or resolution—will guide you toward the right choice.

Essential Software and Tools for 3D Printing

The journey into 3D printing does not end with selecting a printer; it also involves utilizing software tools that facilitate design and preparation of models for printing. CAD (Computer-Aided Design) software is essential for creating custom designs. Programs like Tinkercad are user-friendly and suitable for beginners, while more advanced software like SolidWorks or Autodesk Fusion 360 offers extensive features for professional designers.

These tools allow users to create intricate models tailored to their specific needs. Once a model is designed, it must be sliced into layers using slicing software before it can be printed. Slicing software translates the 3D model into G-code, which contains instructions for the printer on how to build each layer.

Popular slicing programs include Cura and PrusaSlicer, both of which offer customizable settings for print speed, layer height, and infill density. Additionally, many slicers provide previews of the print path, allowing users to visualize how the printer will execute the job. Familiarity with these software tools is essential for optimizing print quality and ensuring successful outcomes.

Materials for 3D Printing: Filaments, Resins, and More

The choice of materials in 3D printing significantly impacts the final product’s properties and applications. For FDM printers, thermoplastic filaments are the most common materials used. PLA (Polylactic Acid) is a popular choice among beginners due to its ease of use and biodegradable nature.

It prints at lower temperatures and adheres well to the print bed, making it ideal for various projects. ABS (Acrylonitrile Butadiene Styrene) is another widely used filament known for its strength and durability but requires higher temperatures and proper ventilation due to fumes released during printing. In contrast, resin-based printers utilize photopolymer resins that cure under UV light.

These resins can produce highly detailed prints with smooth surfaces but often require post-processing steps such as washing and curing under UV light after printing. There are various types of resins available, including standard resins for general use, flexible resins for creating bendable parts, and castable resins designed for jewelry making or dental applications. Understanding the properties of different materials allows users to select the best option for their specific projects.

Getting Started with 3D Printing: Step-by-Step Guide

Embarking on your 3D printing journey can be an exciting yet daunting task. To simplify the process, it’s helpful to follow a step-by-step guide that covers everything from setup to execution. First, begin by assembling your 3D printer according to the manufacturer’s instructions.

This may involve attaching components such as the print bed and extruder or calibrating the printer’s axes to ensure accurate movement.

You can either create your own model using CAD software or download pre-made designs from repositories like Thingiverse or MyMiniFactory.

Finally, save the G-code file onto an SD card or send it directly to your printer if it supports USB connectivity. With everything prepared, load your filament into the printer and start the print job.

It’s advisable to monitor the initial layers closely to ensure proper adhesion to the print bed and detect any potential issues early on. Once completed, allow the print to cool before removing it from the bed to avoid warping or damage.

Troubleshooting Common Issues in 3D Printing

Despite its many advantages, 3D printing can present various challenges that may hinder successful prints. One common issue is warping, which occurs when corners of a print lift off the bed during printing due to uneven cooling or poor adhesion. To mitigate this problem, ensure that your print bed is level and properly heated if using materials prone to warping like ABS.

Additionally, using adhesives such as glue sticks or specialized bed adhesives can enhance adhesion. Another frequent issue is stringing, where thin strands of filament are left between parts of a print due to oozing during travel moves. This can be addressed by adjusting retraction settings in your slicing software—specifically increasing retraction distance or speed can help minimize this effect.

Cleaning the nozzle regularly also prevents clogs that can lead to inconsistent extrusion and other printing problems.

Expanding Your Skills: Advanced Techniques and Tips

As you become more comfortable with basic 3D printing techniques, there are numerous advanced methods you can explore to enhance your skills further. One such technique is multi-material printing, which allows you to combine different filaments in a single print job. This can be achieved using dual-extruder printers or by manually swapping filaments during printing.

Multi-material prints enable you to create objects with varying colors or properties—such as combining flexible TPU with rigid PLA for functional prototypes. Another advanced technique is post-processing, which involves refining your printed objects after they come off the printer. This can include sanding surfaces for a smoother finish, painting models for aesthetic appeal, or even using chemical smoothing methods with acetone vapor for ABS prints to achieve a glossy look.

Learning about these techniques not only improves the quality of your prints but also expands your creative possibilities in 3D design.

Exploring the Possibilities: Fun Projects and Ideas for 3D Printing

The versatility of 3D printing opens up a world of creative projects that cater to various interests and skill levels. For beginners looking for fun yet manageable projects, creating custom phone cases or simple toys can be an excellent starting point. These projects allow you to practice design skills while producing functional items that can be personalized according to individual preferences.

For those with more experience, consider tackling more complex projects such as designing intricate jewelry pieces or creating custom mechanical parts for robotics applications. The ability to produce unique items tailored specifically to your needs is one of the most exciting aspects of 3D printing. Additionally, community challenges such as designing items for local charities or participating in themed contests can inspire creativity while contributing positively to society.

As you delve deeper into this fascinating technology, you will discover endless possibilities limited only by your imagination and willingness to experiment with new ideas and techniques in 3D printing.

If you’re diving into the world of 3D printing as a hobbyist, you might also be interested in exploring other tech innovations that can complement your creative journey. A related article that could pique your interest is about unlocking your creative potential with the Samsung Galaxy Book Flex2 Alpha. This device offers powerful features that can enhance your design and modeling tasks, making it a great companion for 3D printing enthusiasts. You can read more about it in the article titled “Unlock Your Creative Potential with the Samsung Galaxy Book Flex2 Alpha.” This article provides insights into how this versatile laptop can support your creative projects, from concept to creation.

FAQs

What is 3D printing?

3D printing is a manufacturing process that creates a physical object from a digital design. It works by adding material layer by layer to build up the final product.

What are the different types of 3D printing technologies?

There are several types of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP).

What materials can be used for 3D printing?

Common materials used for 3D printing include thermoplastics like PLA and ABS, as well as metals, ceramics, and even food-grade materials for edible creations.

What are some popular 3D printing software programs?

Popular 3D printing software programs include Tinkercad, Fusion 360, SolidWorks, and Blender. These programs are used to create and modify 3D models before sending them to the 3D printer.

What are some common applications of 3D printing for hobbyists?

Hobbyists use 3D printing for a wide range of applications, including creating custom figurines, cosplay props, replacement parts for household items, and prototypes for personal projects.

What are some important considerations for beginners getting into 3D printing?

Beginners should consider factors such as the type of 3D printer to purchase, the cost of materials, the learning curve of 3D modeling software, and the time required for printing and post-processing.