The prospect of human exploration and settlement beyond Earth necessitates the development of self-sustaining capabilities. One crucial aspect of this endeavor is the construction of habitats. Traditional methods of transporting pre-fabricated modules from Earth are economically unfeasible and logistically challenging for large-scale operations. This article explores the concept of 3D printing habitats using Martian regolith, a potential avenue for in-situ resource utilization (ISRU) to reduce reliance on terrestrial supplies and facilitate long-term extraterrestrial presence.

Before delving into the specifics of 3D printing, it is essential to understand the formidable challenges presented by the Martian environment. These challenges directly influence the design and material requirements for any habitat.

Atmospheric and Pressure Considerations

Mars possesses a thin atmosphere, primarily carbon dioxide, with an average surface pressure of approximately 610 Pascals, less than 1% of Earth’s sea-level pressure. This necessitates habitats that can maintain a breathable internal atmosphere under significant pressure differentials. The structural integrity of the habitat must withstand these internal pressures, acting as a pressure vessel in a vacuum.

Radiation Exposure

The lack of a substantial magnetic field and a thin atmosphere exposes the Martian surface to high levels of cosmic radiation and solar energetic particles. This radiation poses a significant health risk to human occupants, including an increased risk of cancer, acute radiation sickness, and damage to the central nervous system. Habitats must incorporate effective radiation shielding, often requiring substantial mass.

Temperature Extremes

Mars experiences extreme temperature fluctuations. Diurnal cycles can see temperatures swing by over 100°C, with averages ranging from -63°C to -18°C. Polar regions can drop to -140°C, while equatorial summer days might briefly exceed 20°C. Habitats require robust thermal insulation and active temperature control systems to maintain habitable internal conditions.

Dust and Perchlorates

The Martian surface is covered in fine dust, which is abrasive and electrically charged, posing a threat to equipment and human health. Furthermore, perchlorates, a class of chemical compounds, are present in the regolith. These are toxic to humans and can be corrosive, necessitating careful handling and potential removal from construction materials.

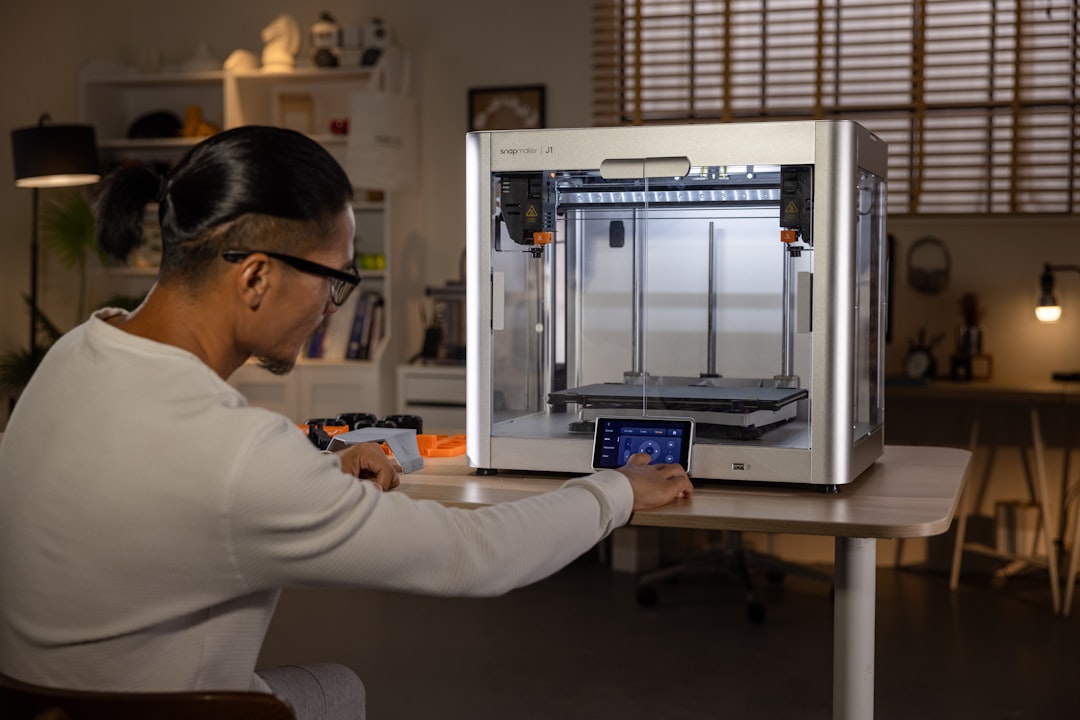

Recent advancements in 3D printing technology have opened up exciting possibilities for constructing habitats on Mars using local materials, specifically Martian regolith. An insightful article that delves into this innovative approach can be found at this link. The use of regolith not only reduces the need to transport building materials from Earth but also leverages the unique properties of Martian soil to create sustainable living environments for future astronauts.

Martian Regolith as a Resource

Martian regolith, the loose surface material covering the planet, is the primary readily available local resource for construction. Its composition and properties are critical to its utility in 3D printing.

Compositional Overview

Regolith is primarily composed of silicon dioxide (silica), iron oxides (which give Mars its reddish hue), aluminum oxides, magnesium oxides, calcium oxides, and titanium oxides. It also contains volatile elements such as sulfur, chlorine, and trace amounts of water ice, particularly in higher latitudes or beneath the surface. The exact composition can vary significantly depending on the landing site.

Mechanical and Chemical Properties

The mechanical properties of regolith, such as particle size distribution, cohesiveness, and bulk density, are crucial for its use as a building material. Its fine particulate nature, often described as similar to talcum powder but with sharp edges, makes it challenging to handle but potentially suitable for binding. Chemically, the presence of various oxides offers opportunities for sintering or chemical binding processes.

Water Extraction Potential

While not abundant, water ice exists within the Martian regolith, particularly at higher latitudes and beneath the surface in shadowed regions. The ability to extract this water could be transformative, providing not only drinking water and oxygen for life support but also a binding agent for certain 3D printing processes or as feedstock for creating geopolymers.

3D Printing Technologies for Martian Habitats

Several additive manufacturing technologies are being explored for their potential to construct habitats on Mars. Each method presents distinct advantages and limitations when applied to the unique constraints of the Martian environment and regolith.

Contour Crafting

Contour Crafting is a large-scale 3D printing process that uses a robotic gantry system to extrude layers of concrete-like material. On Earth, this technology has been demonstrated for rapid construction of terrestrial buildings. For Mars, the “ink” would need to be formulated from Martian regolith, potentially mixed with a binding agent.

Extrusion-Based Systems

These systems involve pumping a semi-liquid, high-viscosity material through a nozzle, depositing it layer by layer. The key challenge lies in developing a binder that is either readily available on Mars, extractable from regolith, or can be transported from Earth in minimal quantities. Potential binders include sulfur, polymers, or water-activated cements.

Advantages and Challenges

Contour Crafting offers the potential for rapid construction of complex geometries with high material deposition rates. It also allows for the integration of utilities (electrical conduits, plumbing) during the printing process. However, the process requires consistent material consistency and viscosity, which can be difficult to achieve with raw, unprocessed regolith. Dealing with fine dust and low gravity during extrusion also poses engineering challenges.

Solar Sintering

Solar sintering involves using concentrated solar energy to melt and fuse regolith particles together. This method leverages the abundant solar energy available on Mars, particularly when combined with parabolic mirrors or Fresnel lenses to focus sunlight.

Principle of Operation

High-intensity solar radiation heats the regolith to temperatures between 1000°C and 1500°C, causing the particles to fuse without fully melting. This process forms a ceramic-like material. The process requires precise control of temperature and exposure time to achieve desired material properties.

Material Properties and Durability

The resulting material from solar sintering is expected to be durable, dense, and resistant to radiation. It would be akin to a low-grade ceramic or brick. The porosity and strength would depend on the sintering parameters and the specific composition of the regolith. This method eliminates the need for imported binders, representing a truly in-situ resource utilization approach.

Energy Requirements and Dust Mitigation

While leveraging solar energy, the process requires efficient energy collection and focusing systems. Dust accumulation on mirrors could significantly reduce efficiency, necessitating robust cleaning mechanisms. Furthermore, the extreme temperature differentials created during sintering could induce thermal stresses in the resulting structures.

Binder Jetting

Binder jetting involves depositing a liquid binding agent onto a layer of powdered regolith. After each layer of binder is deposited, a new layer of regolith powder is spread, and the process repeats until the object is formed.

Binder Selection and Curing

The selection of a suitable binder is paramount. It needs to be effective in low gravity and potentially low temperatures. Binders could be organic polymers transported from Earth, or inorganic binders derived from Martian resources, such as sulfur or potentially even water if available. Curing mechanisms, whether thermal or chemical, would also need to be optimized for the Martian environment.

Post-Processing Requirements

Binder jetting typically produces “green” parts that are not yet fully strong. Post-processing steps, such as infiltration with a stronger material, sintering (at lower temperatures than direct solar sintering), or chemical curing, would be necessary to achieve the required structural integrity. This adds complexity to the manufacturing process.

Habitat Design Considerations

Beyond the manufacturing process, the design of habitats printed from Martian regolith must address fundamental requirements for human sustenance, protection, and operational efficiency.

Structural Integrity and Pressure Containment

A primary design consideration is the ability of the 3D-printed structure to withstand the internal pressure differential. Habitat walls must be thick enough and composed of materials with sufficient tensile and compressive strength. Double-hulled or inflatable structures within a rigid outer shell could offer redundancy and enhanced safety.

Shape and Geometry

Dome shapes, toroidal structures, or subterranean designs offer inherent mechanical advantages for pressure containment and radiation shielding. These geometries distribute stress more effectively than flat walls. Subterranean habitats, whether buried or excavated, would utilize the regolith overburden for significant radiation and micrometeoroid protection.

Reinforcement Techniques

While regolith offers bulk, its tensile strength might be limited. Integrating reinforcement materials, such as basalt fibers extracted from Martian rocks or even metallic wires if available, could significantly enhance structural integrity and crack resistance. This is akin to rebar in terrestrial concrete.

Radiation Shielding

Radiation shielding is a non-negotiable requirement. The amount of shielding needed dictates the thickness and density of the habitat walls or the depth of burial.

Layered Materials

A layered approach to shielding may be optimal. Dense materials like Martian regolith offer primary protection, while lighter, hydrogen-rich materials (if they can be manufactured or extracted) could further attenuate secondary radiation. Water, if extensively available, is an excellent radiation shield.

Subterranean and Berm Designs

Burying habitats beneath several meters of regolith or constructing berms (e.g., using contour crafting to build a protective mound around the habitat) provides the most effective passive radiation shielding due to the significant mass of overburden. This approach inherently leverages the bulk of the available regolith.

Thermal Control and Insulation

Maintaining a stable internal temperature in the face of extreme external fluctuations is critical for crew comfort and equipment operation.

Passive Insulation Strategies

Thick regolith walls themselves offer some insulative properties. Incorporating voids or creating multi-layered walls with vacuum gaps could further enhance thermal insulation, mimicking terrestrial thermos flasks.

Active Environmental Control Systems (ECLSS)

Even with passive strategies, active environmental control and life support systems (ECLSS) will be necessary. These systems will regulate temperature, humidity, and atmospheric composition, requiring efficient power supplies and closed-loop recycling of resources.

Recent advancements in the field of 3D printing have opened up exciting possibilities for constructing habitats on Mars using Martian regolith. This innovative approach not only addresses the challenges of building in an extraterrestrial environment but also utilizes local materials, making it a sustainable solution for future colonization efforts. For further insights into this groundbreaking technology and its implications for space exploration, you can read a related article on the topic at Enicomp’s blog.

Challenges and Future Outlook

| Metric | Value | Unit | Description |

|---|---|---|---|

| Printing Speed | 10 | cm/hour | Average speed of 3D printer depositing Martian regolith material |

| Layer Thickness | 5 | mm | Thickness of each printed layer in the habitat structure |

| Compressive Strength | 15 | MPa | Strength of printed regolith-based material under compression |

| Radiation Shielding Effectiveness | 70 | % | Percentage reduction of cosmic radiation through regolith walls |

| Habitat Wall Thickness | 30 | cm | Recommended thickness for adequate protection and insulation |

| Energy Consumption | 5 | kWh/m³ | Energy required to print one cubic meter of habitat material |

| Material Utilization Efficiency | 85 | % | Percentage of regolith material effectively used in printing |

| Operational Temperature Range | -20 to 30 | °C | Temperature range in which the 3D printing process is effective on Mars |

While promising, 3D printing habitats on Mars presents substantial technical, logistical, and scientific challenges that require dedicated research and development.

Material Processing and Standardization

The raw Martian regolith is not a uniform, consistent material. Developing robust processes for sieving, sorting, and potentially chemically altering the regolith to meet specific printing material requirements is crucial. Standardizing “Martian cement” or “Martian ceramic” formulations will be a significant undertaking.

Robotics and Autonomy

The long communication delays between Earth and Mars (up to 20 minutes one-way) necessitate a high degree of autonomy for robotic construction systems. These systems must be capable of operating for extended periods without direct human intervention, performing tasks like material gathering, processing, printing, and self-maintenance.

Energy Infrastructure

Large-scale 3D printing operations will require substantial power. This necessitates the development and deployment of robust Martian power infrastructure, likely involving advanced nuclear fission reactors or large-scale solar arrays with efficient energy storage solutions.

Validation and Certification

Before humans can inhabit these structures, rigorous testing and validation of the materials and construction processes in simulated Martian environments are essential. Certifying these structures for human habitation, considering long-term degradation and failure modes, will be a critical step.

Phased Deployment Strategy

A likely scenario involves a phased deployment: initial robotic missions demonstrating small-scale printing, followed by larger, more complex structures, and eventually full habitats. Early human missions might bring smaller, pre-fabricated modules for immediate shelter, while robotic construction continues, expanding living and working spaces.

In summary, 3D printing habitats using Martian regolith offers a pragmatic pathway towards sustainable extraterrestrial settlement. It represents a paradigm shift from transporting everything from Earth to leveraging available planetary resources. The metaphor of Mars as a quarry rather than just a destination encapsulates this approach. While significant challenges remain, the foundational research and technological advancements continue to pave the way for a future where human presence on Mars is not merely temporary, but enduring.

FAQs

What is Martian regolith and why is it important for 3D printing habitats?

Martian regolith is the layer of loose, fragmented material covering the solid bedrock on Mars, composed mainly of dust, soil, and broken rock. It is important for 3D printing habitats because it can be used as a raw material to create building structures directly on Mars, reducing the need to transport construction materials from Earth.

How does 3D printing technology work for building habitats on Mars?

3D printing technology for Martian habitats involves using robotic printers that layer and fuse regolith-based materials to form walls and other structural components. This additive manufacturing process allows for precise, automated construction of complex shapes and durable shelters suitable for the Martian environment.

What are the advantages of using 3D printed habitats on Mars?

The advantages include significant cost savings by minimizing payload weight from Earth, faster construction times, the ability to create customized and complex designs, and enhanced safety by providing radiation shielding and protection from harsh Martian weather conditions.

What challenges exist in 3D printing habitats with Martian regolith?

Challenges include developing binding agents or sintering techniques to solidify regolith, ensuring structural integrity under Mars’ gravity and temperature extremes, dealing with dust contamination, and creating reliable autonomous systems capable of operating in the remote and harsh Martian environment.

Are there any current projects or experiments related to 3D printing with Martian regolith?

Yes, several space agencies and research institutions are conducting experiments using simulated Martian regolith on Earth to test 3D printing methods. NASA and ESA have ongoing projects exploring regolith-based construction, and private companies are also developing technologies aimed at future Mars missions.